1770

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

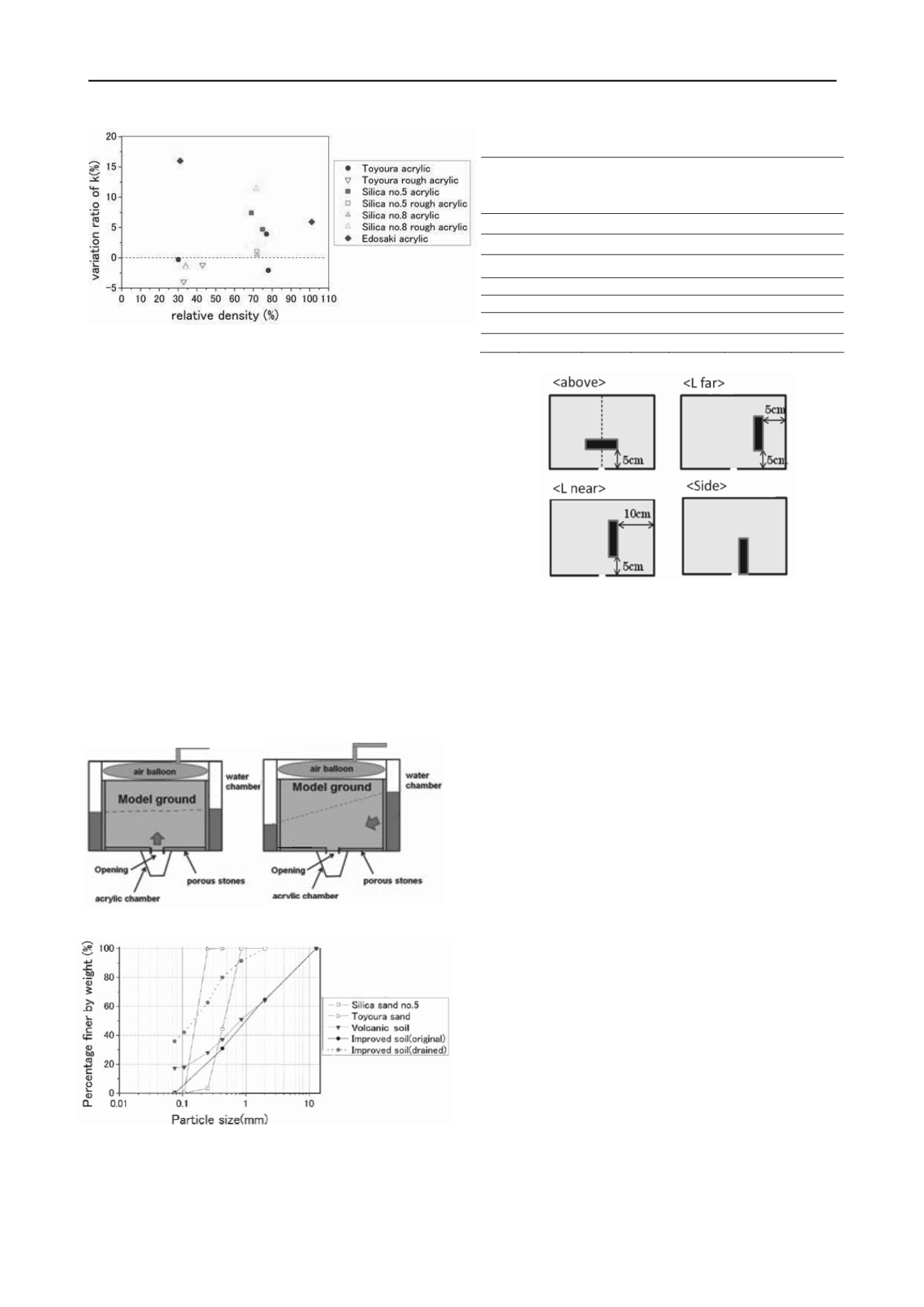

3 MODEL TEST WITH CONSTANT WATER LEVEL

3.1

Test apparatus and conditions

Test apparatus is schematically shown in Figure 3. This

apparatus is composed of three parts: center soil chamber, right

and left side water chambers. Porous stones were put between

the soil chamber and water chambers, and bottom plate of the

soil chamber. Through the porous stone, water was penetrated

freely. There was a 5mm width opening at the center of the

bottom plate of the soil chamber, which was closed initially. A

wooden block (2.1cm length, 10cm height, 8cm width) was put

into the ground with various positions, which simulated a buried

structure. It was painted and water penetration was prevented.

Positions of the block were shown in Figure 5. Overburden

weight was equivalent to the weight at 100cm deep of the

ground. Toyoura sand, silica sand no.5, improved soil and

volcanic soil were used. The improved soil was utilized at

construction site, and the volcanic sand caused a sinkhole

accident Particle size distributions of tested materials are shown

in Figure 4. All test cases are shown in Table 1.

3.2

Test procedure

The model ground was compacted on around optimum water

content. Water was penetrated from the bottom porous stone

plate or side water chamber, until horizontal or inclined water

level was kept steadily. After the model ground became stable,

opening was released and then water and soil was flown out

from the opening

3.3

Test result

Position of the block changed the situation of the cavity

formation. Dotted line in Figure 6 represented the water level

just before the opening released. When water level was inclined

and water was flown from right to left as shown in Figure 7,

cavity was generated below the block but overall tendency of

the formation was similar as the case without the block. From

Figure 7, it was suggested that water was penetrated around the

block by putting blue ink to water.

Improved soil prevented soil outflow in dense condition but

a cavity was expanded in loose condition. Particle size

distribution of drained soil was investigated and the result was

shown in Figure 4. It was suggested that drained soil contained

much more fines than original material. The amount of fines in

drained soil of case InL was 50% of whole amount of fines in

the model ground, which proposed that fines flown out from

large area. Test results of horizontal water flow conditions were

shown in Table 1.

“

Ratio of soil loss” in Table 1 means ratio

of weight of soil loss to total dry weight of soil in the model

ground.

“

Elapsed time” in Table 1 means time which took to

achieve the specified water level (10cm) which indicates

permeability. From Table 1, position of the block influenced not

on rise of water level but on soil outflow. On the other hand,

increasing of water level was very rapid in volcanic soil which

didn’t cause soil outflow. Loose condition of improved soil

caused much more rapid rise of water level than dense condition

of that which suggested the risk of soil outflow in large

hydraulic gradient.

Code Material

Position

of the

block

Dc or

Dr

(%)

Water

level(cm)

Ratio of

soil

outflow(%)

Elapsed

time

(sec)

Sn Silica no.5 None Dr 80

7.5

7.8

---

Tf

Toyoura

L far Dr 80

10

15.4 220

Ta Toyoura

Above Dr 80

10

7.1 220

Ts Toyoura

Side Dr 80

10

11.5 270

Vn Volcanic None Dr 80

10

0 150

InD Improved None Dc 90

10

0 340

InL Improved None Dc 75

10

0.4 150

Table 1. Test conditions with Constant & Horizontal water flow condition

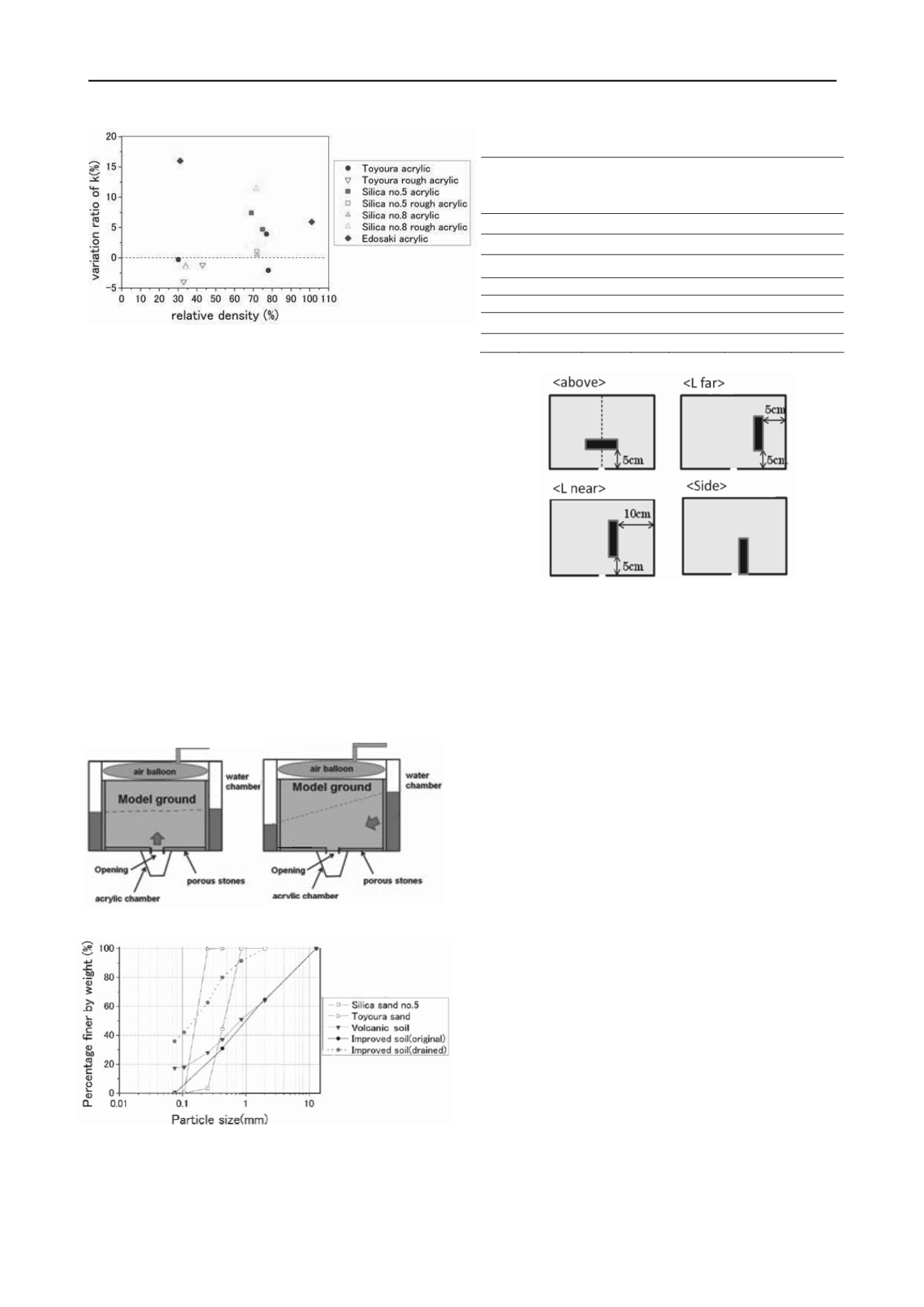

Figure 2. Effect of cylinder’s small shaking on permeability

Figure 5. Positions of the block

Figure3

.

Schematically figure of the soil chamber with constant water

level

<Inclined >

<Horizontal

>

Figure

4. Particle size distribution