1761

Technical Committee 204 /

Comité technique 204

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

sch

by 2 m work segments.

ually.

ments of existing footings, exceeding the 10 mm admissible

value.

It was decided not to take into account existing piles made in

2005. This decision was based on two facts.

Firstly, the static load tests on existing piles showed great

scatter in results. In fact, bearing capacity was two times lower

then its design. Secondly, the connection of reinforced concrete

capping beam to existing foundation made of crushed stone was

questionable. Assesment of existing foundation and its structural

integrity confirmed that the major part of the building load still

transfered through existing strip foundation despite the presence

of underpining piles.

With regard to aforementioned facts, a decision was made to

cancel piling from the analyses to ensure a safety margin.

There were considered various trench retaining options: root

piles, pressed-in piles, subsoil stabilization that could be techni-

cally possible in congested basement premises. However, none

of the existing methods could resolve the above issues and en-

sure an adequate safety margin. Fast fabricated root piles usually

have technological settlements unacceptable for the building in

question. Pressed-in piles, having no such disadvantage, were

used for the Bolshoi Theater refurbishment project, but they

proved to be very labor intensive, and their installation

required much more time than the time, remaining before

the P.I. Tchaikovsky Competition. Subsoil stabilization is not a

sufficiently safe solution, as in such soils it was difficult to en-

sure adequate quality of respective construction operations.

In view of all above mentioned circumstances a decision

was made to support 4.0...4.5 m ducts with root piles, reinforced

with steel pipes.

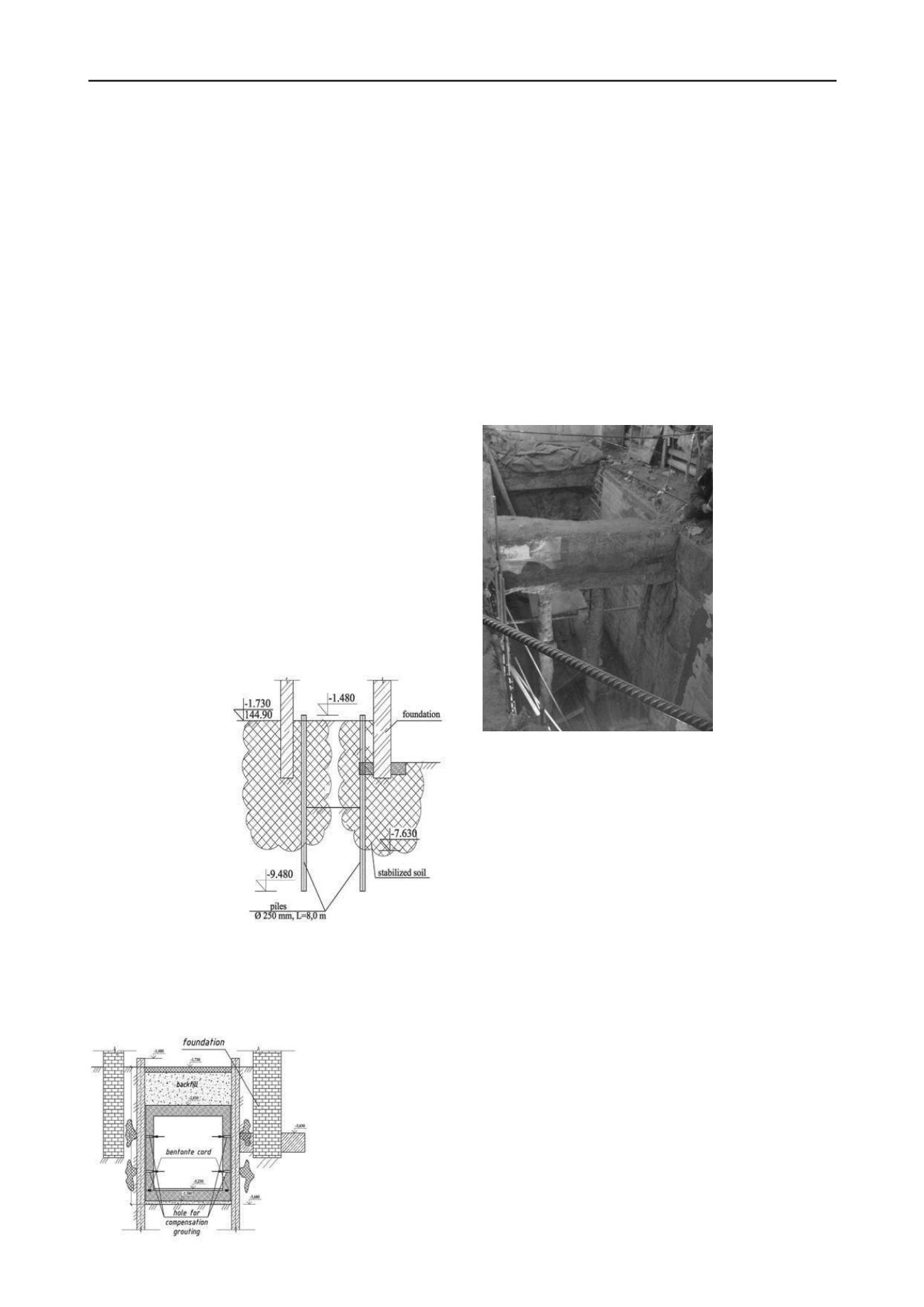

Realization of the project required a technique and a se-

quence of the underground operations, which would minimize

the construction the

impact of construc-

tion works on the

building

structure

(Petruknin V.P. et al.

2011). At the initial

stage the soil was

grouted with Micro-

dur suspension, then

the supporting root

piles were erected

(Figure 6), followed

by stagewise soil

excavation to design

depths and raft con-

creting, only then the

duct walls and the

floor were erected.

Figure 6. Soil stabilization layout and retaining piling

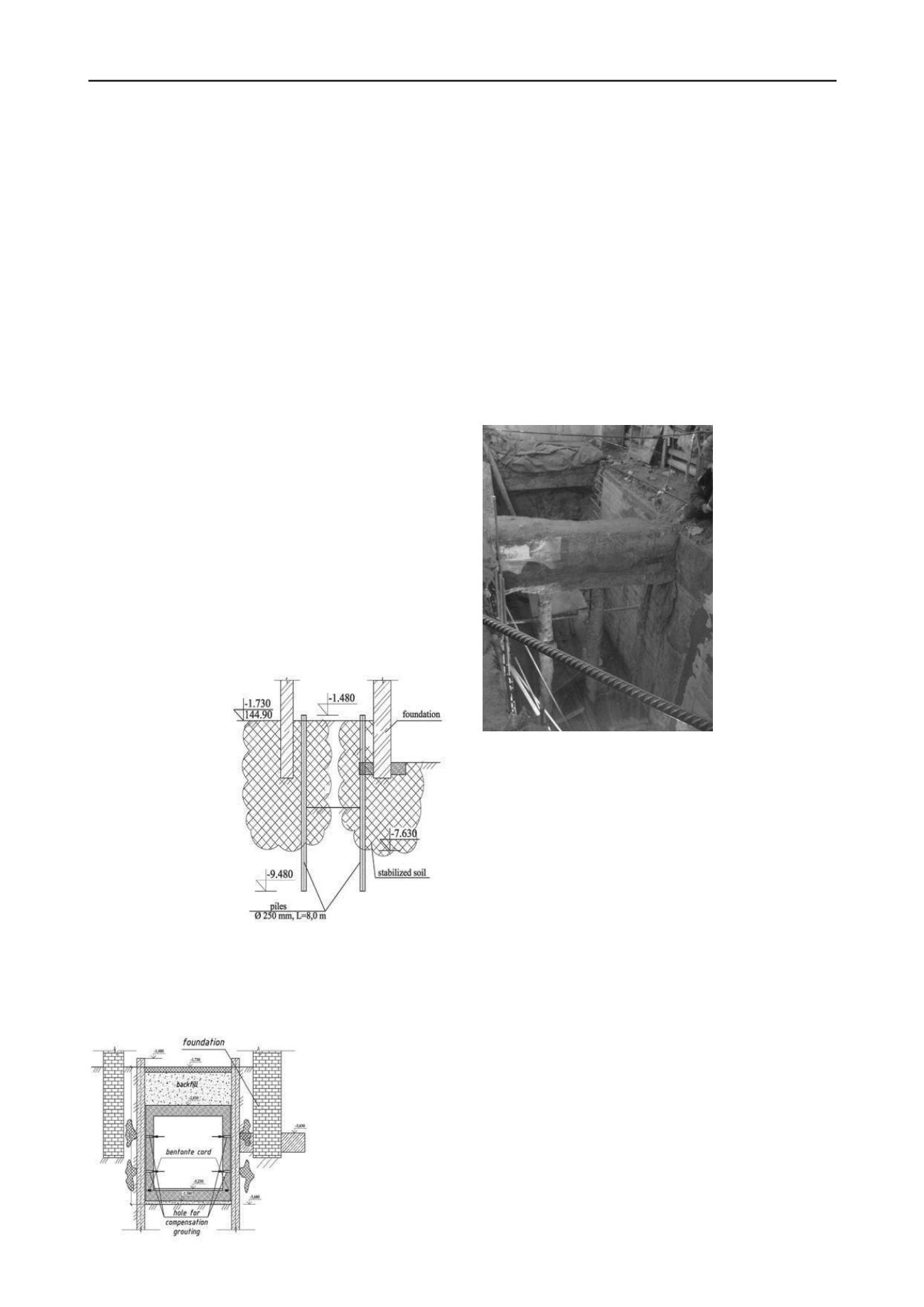

The reafter, in order to change the subsoil stress and strain

behavior multiple compensation grouting was done behind the

trench lining (Figure

7). Geodetic monitor-

ing of the footing

settlements showed

that the resulting

upheaval of markers

was up to 2…3 mm.

Figure 7. Duct concret-

ing layout with the com-

pensation grouting

eme

As is known the root piles’ advantage is their low cost and

fast erection, the only drawback is the respective technological

settlements of footings, which can be as much as several centi-

meters (Shulyatjev O.A. et al, 2008; Petrukhin V.P. et al, 2008).

In order to exclude technological settlements due to root piling

there were performed tests, and a drilling set-up was developed,

protected by a RF patent (Petrukhin V.P., Popsuenko I.K., Shu-

lyatjev O.A., 2011), that compensated soil stress-strain behavior

variation due to drilling by stagewise vertical pressurizing to-

gether with filling the bore hole with cement-sand grout, whose

composition excluded sedimentation. The operations were per-

formed gradually

According to the above mentioned patent the hole drilling

was accompanied by compaction and hole walls troweling to

prevent water-saturated liquefied soil falling in the borehole.

Figure 8 shows a photograph of a duct segment under the Big

Hall, dug out manually to the design depth.

At the fore-

front root piles,

made in 2005, are

visible, they are

joined together by

a concrete raft, they

are a sort of struts.

Soil

excavation

from ducts is a

rather

labor-

intensive process,

therefore, as di-

mensions of the

premises

were

small, the soil was

dug out man

Figure 8. 4.5 m deep service duct

In order to reduce footings settlements during ducts mining

operations the soil under bearing walls was grouted with “Mi-

crodur” suspension.

Therefore, the subsequent soil excavation showed that soil

stabilization had been done adequately, however, practically no

traces of grouting were discovered at some points in spite of the

customer permanent strict control and designer supervision.

Thus, it indirectly proved that the safer selected option i.e., re-

taining piles, was correct.

Soil mining under bearing walls of the building was a com-

plicated issue. As is mentioned above, it is wrong during soil

mining to rely on earlier arranged root piling. Therefore, a steel

frame set-up was elaborated for 4,5 m deep ducts, which sup-

ported a part of the wall, under which the soil was dug out.

Mining 1,8 deep ducts was even more difficult. Notably,

shallow ducts mining was performed not only in soil, it was

often done along the body of rabble stone footing (the footing

width was up to 1,5 m), therefore, soil excavation looked as

non-mechanized mining (all operations were manual).

Underground development project involved various geo-

technical operations that required on-line integrated geotechnical

monitoring, performed by a specialized company in the most

optimal way. Moreover, the designer company (Gersevanov

NIIOSP) carried out their own supervision of the vertical and

lateral displacements of the footings and of the Conservatory

building structure. The congested conditions of the refurbish-

ment operations, numerous labor force, multiple material stor-

age sites, etc. restricted installation of an up-to-date on-line set-