1767

Technical Committee 204 /

Comité technique 204

Table 2. Liners properties

Stage Liner

Type of

element

f'

c

MPa

F

R

E

MPa

e

m

EA

MN/m

EI

MNm

2

/m

1 y 2 Primary Cluster 35 0.2 1.00 5,206 0.4 ----

----

Primary Cluster 35 0.2 0.57 2,968 0.4 ----

----

Secondary Plate 50 1.0 0.57 17,152 0.4 6,003 61.3

3 y 4

MPa

f

, F E

c

R

400 4

= liner reduction factor of stiffness

f’

c

= concrete axial unconfined strength

F

R

= reduction modulus due to plastic flow

E

= modulus of elasticity

e

= liner thickness

I

= modulus of inertia

(-) Loading

(+) Unloading

[kN/m

2

]

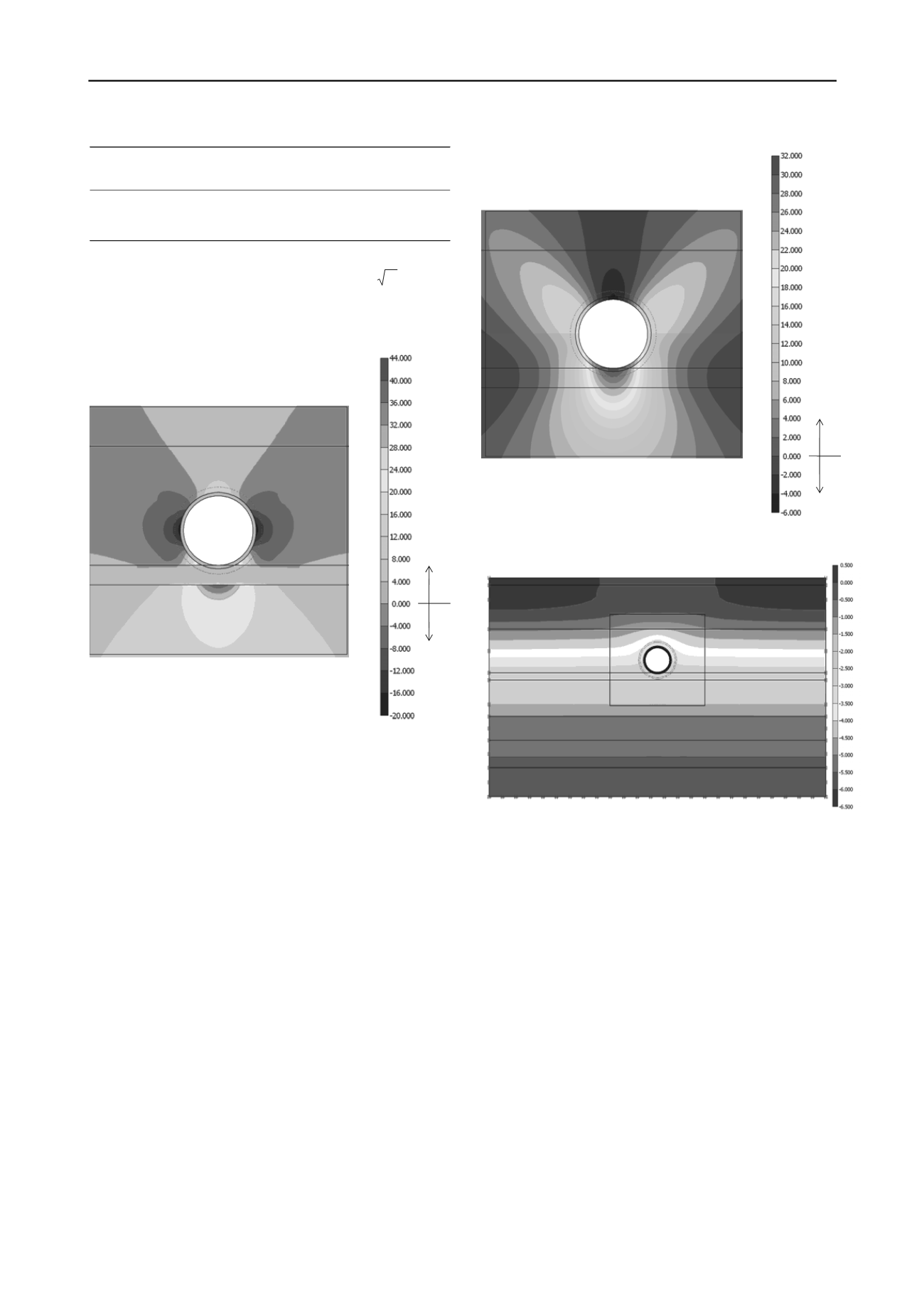

Figure 3. Stage 1, excess of pore pressure

Once the excess of pore pressure is dissipated (stage 2),

effective stresses increase in the soil located below the tunnel.

The clayey soil in this zone becomes a pre-consolidated

material and therefore is less compressible than the soil around

it. Because of that, once the definitive liner is installed (stage 3)

and the excess of pore pressure generated by the water pressure

drawdown is allowed to dissipate (stage 4), the rate of

subsidence of the soil underneath the tunnel decreases (Figure

5). Therefore, the tunnel experiences an apparent emersion with

respect to the surrounding soil.

Such emersion causes the soil around the tunnel to hang

from the primary liner, generating negative skin friction over its

upper part and inducing development of limit stress conditions

in some areas (Figure 6). The forces that try to make the tunnel

move downward induce, in turn, significant upward reaction

forces and some plastification in the hard layer (support layer).

The analysis results show that the final liner is subjected to a

very unfavourable loading condition from a structural point of

view (Figure 7). While the upper part of the tunnel (point A) is

loaded in vertical direction, the lateral sides (point B)

experience confinement loss. This decrease of the horizontal

stress can be estimated in a simple way by applying Terzaghi’s

effective stresses principle, that is:

0

1

K u

x

(1)

where:

x

, is the total horizontal stress increment;

u,

is the

pore pressure increment and

K

0

, is the coefficient of earth

pressure at rest.

(-) Downward

(+) Upward

[*10

-3

m]

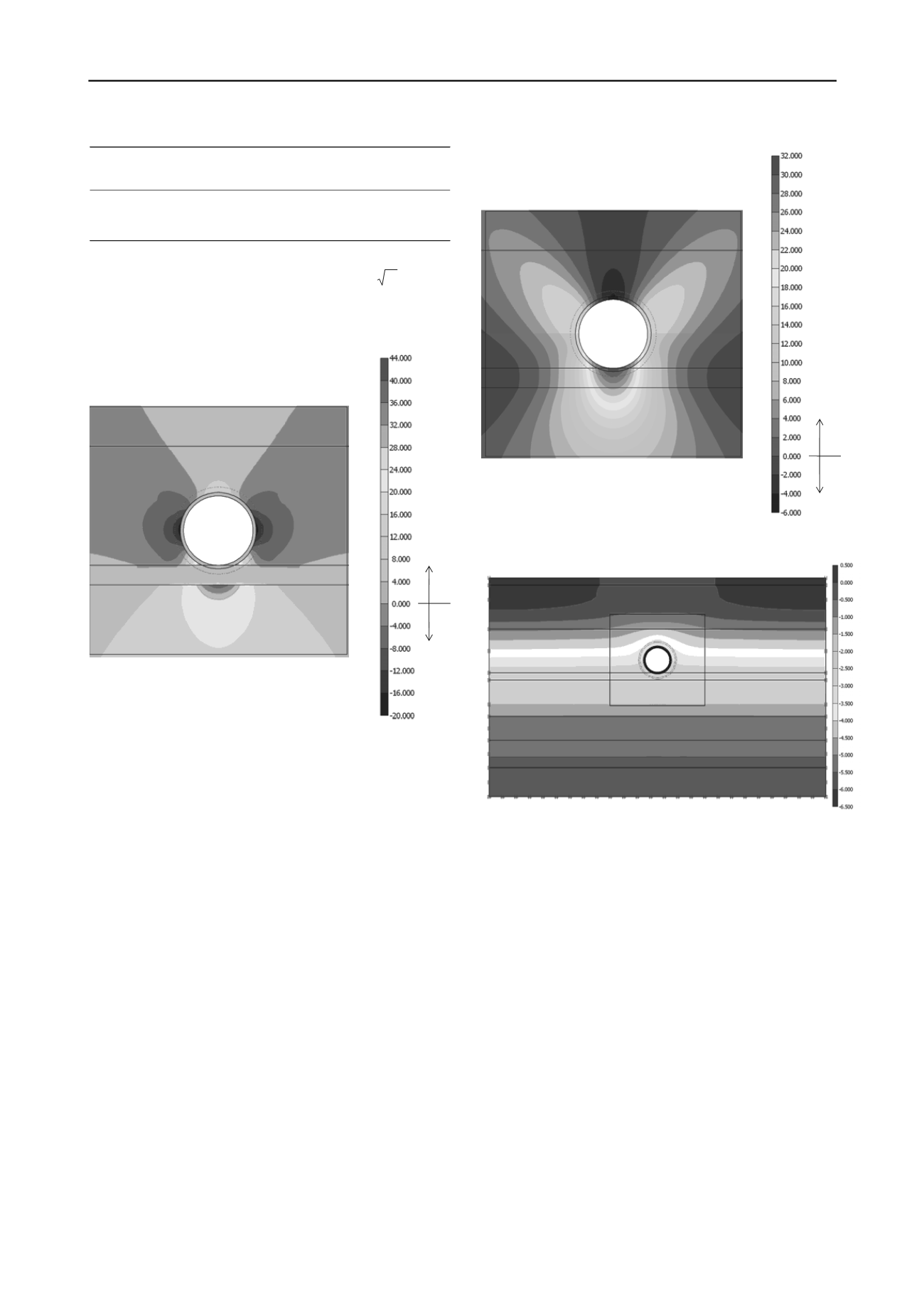

Figure 4. Stage 1, vertical displacements

[m]

Figure 5. Stage 4, vertical displacements

The total stress increment at point A has to be zero as a

result of the drawdown of pore pressure (

y

= 0). Variations

of the total stresses with respect to the amount of piezometric

drawdown at points A and B are displayed on Figure 7. This

figure also presents, for comparative purposes, the results

obtained from finite element modelling.

It can be observed that the total stress at point A estimated

with FEM increases as piezometric drawdown develops. This

can be explained by the fact that the tunnel settles at a lower

rate than the surrounding soil (apparent emersion). Hence, the

soil above the tunnel’s upper part pushes the liner downward,

increasing the vertical stress in this area.

Regarding the horizontal stress (Point B), a significant

difference can be observed between theoretical and FEM

solutions for a zero drawdown. This can be explained by the

fact that during the tunnel excavation stage the primary liner

tends to push laterally the soil located in the side zones,

generating an increment of the horizontal stresses. As the

piezometric drawdown takes place, the FEM solution gets

closer to the theoretical one. It is possible to conclude that the

theoretical solution can be used with confidence for determining

the decrement of the horizontal stresses (confinement loss) on

the sides of the tunnel as a result of pore pressure reduction.

This is not the case for the stress increment that develops on the

tunnel upper part. Differences between both solutions can be