1772

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

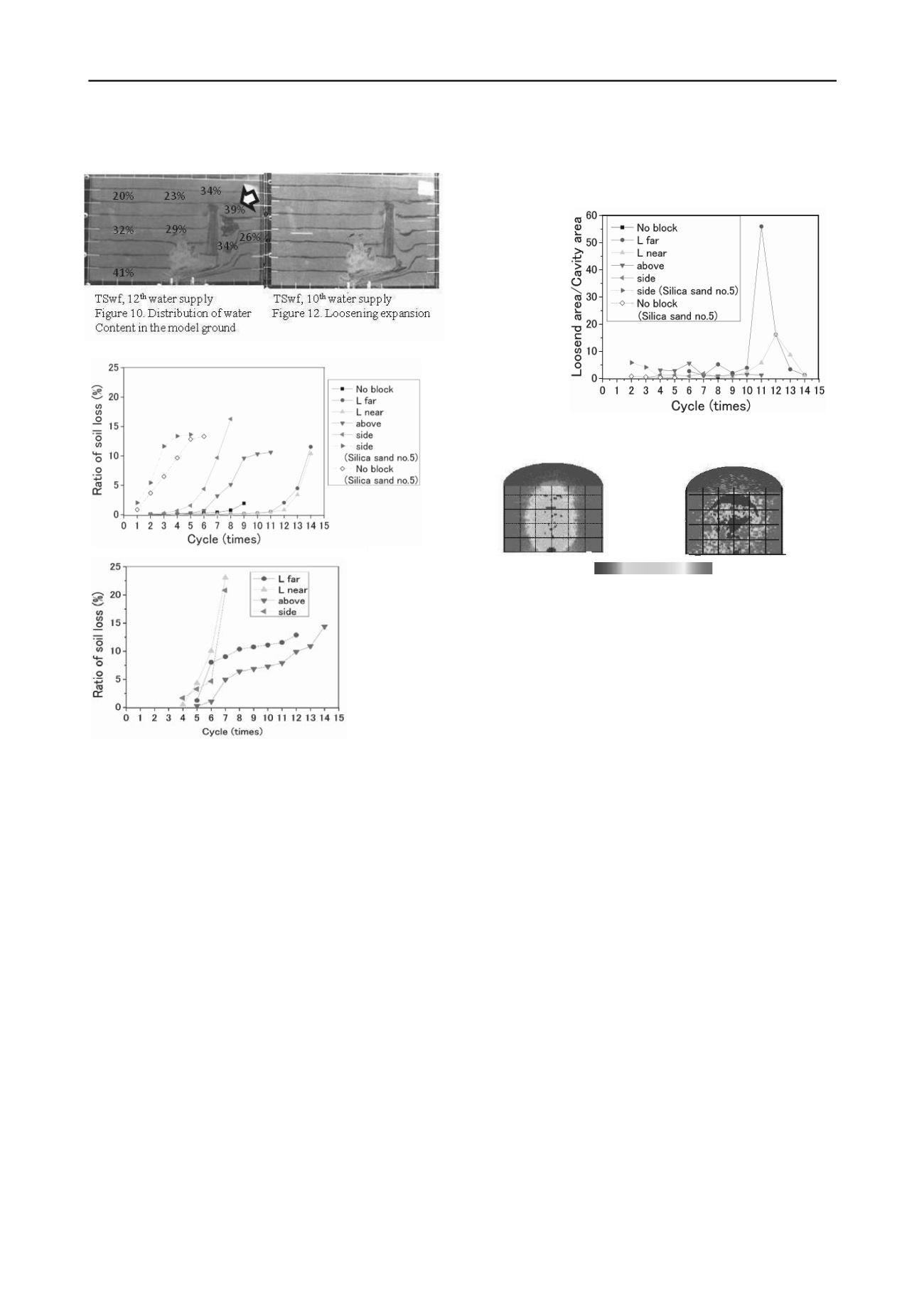

soil loss was larger in the all cases with block than that without

the block.

5 DISCUSSION ABOUT PROCESS OF THE CAVITY

AND LOOSENING EXPANSION

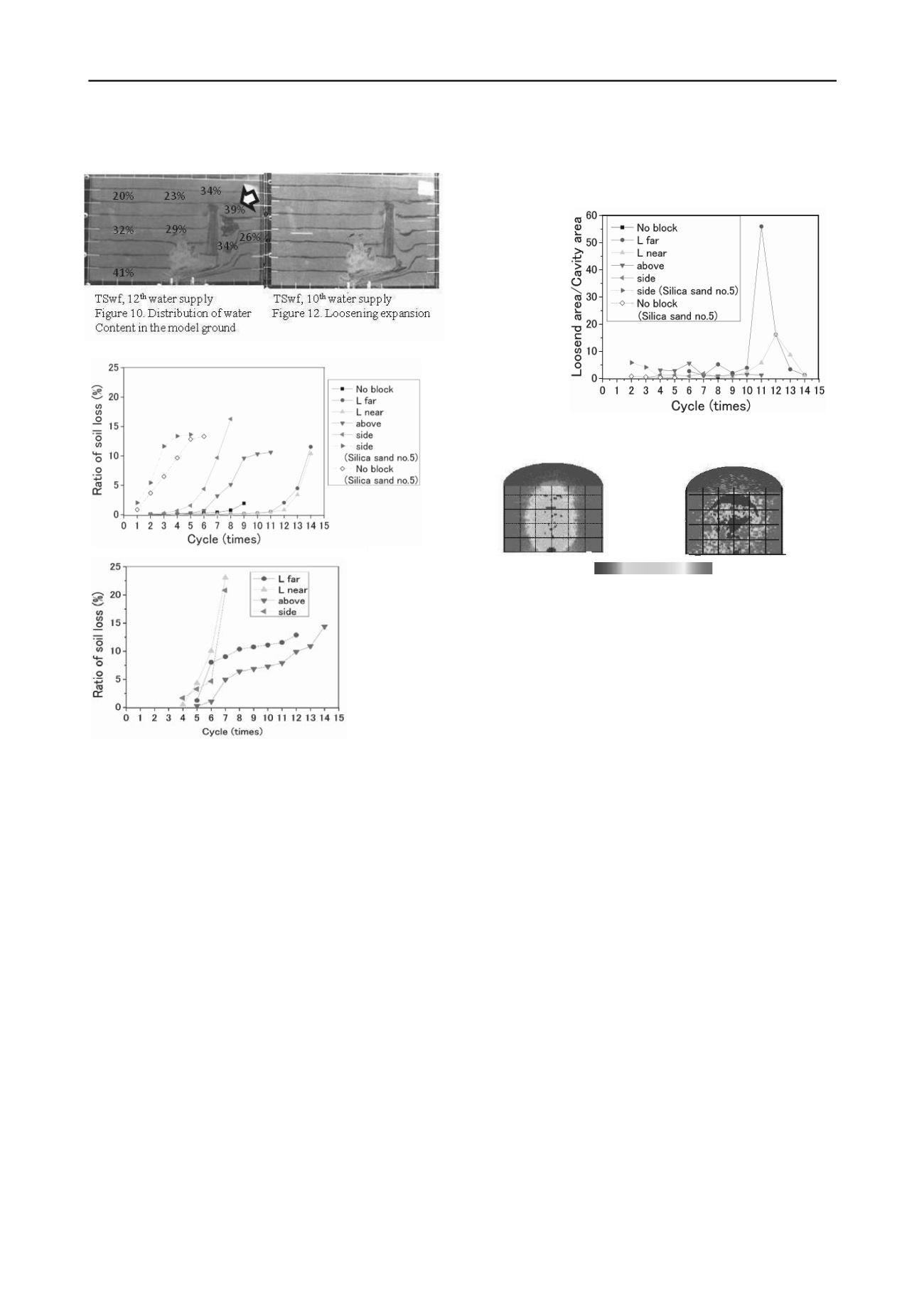

Loosening (low density area) was often generated around the

cavity.

(1

Deformed area around the cavity was observed in

LfarTSw test case by colored sand layers, which was

represented in Figure 12. Later this deformed area became the

cavity as observed in Figure 10. It was obvious that soil outflow

from the cavity area. However, measured soil loss was not

equivalent to that from the cavity. It was proposed that this

phenomenon was caused by two different processes: 1)

expansion of loosening, and 2) soil loss from loosening area.

In the process of 1) expansion of loosening, it was supposed

that expansion of loosening caused cavity’s shrinkage. Area of

loosening and area of cavity was estimated from photographs

taken during the tests and then ratio of loosening area to cavity

area was calculated. As shown in Figure 13, ratio increased

rapidly and then decreased. The test cases which the block was

set at Lfar and Lnear positions, the ratio increased much more

than other cases. This process easily happened in clean uniform

materials such as Toyoura sand and Silica sand no.5. Renuka et

al.(2011) evaluated the stiffness of loosening by cone

penetration test and found that penetration resistance decreased

in loosening area

3)

.

In the second process, it was suggested that fine particles

were flown out from loosening. This process was caused in well

graded materials. (Referring to 3.2) Kenny et al.(1985).

suggested that particles which were larger than four times of

fine particles were necessary for this process.

4)

Mukunoki et

al.(2007)

5)

revealed by CT scanner that formation of loosening

was different from Toyoura sand and natural sand(Referring to

Figure 13), because Toyoura sand was clean uniform sand but

natural sand was well graded sand.

<Opening>

6 CONCLUSION

This paper suggested that the placement of block in the model

ground changed water penetration and sometimes promoted

expansion of the cavity. In addition, gaps between buried

structures and the ground had higher water permeability than

that in the normal ground. The increase of water permeability

and concentration of water penetration around underground

structures may be caused in the practical ground. Two different

processes of generation of loosening are proposed.

7 REFERENCES

1) Kuwano, R, Yamauchi, K., Horii, T. & Kohashi, H.

(2006).Defects of sewer pipes causing cave-in’s in the road.

Proc. of 6th International Symposium on New Technologies

for Urban Safety of Mega Cities in Asia. Phuket: No.H63.

2) Sato, M. & Kuwano, R. (2010).

Model Tests for the

Evaluation of Formation and Expansion of a Cavity in the

ground

. Proc. of the 7th International Conference on Physical

Modelling in Geotechnics Zurich: 581-586.

3) Renuka,S. & Kuwano,R. (2011).

Formation and evaluation

of loosened ground above a cavity by laboratory model test

with uniform sand

, Proc. of 13th International Summer

Symposium, Uji, Japan: .211- 214.

4) Kenny,T.C.,Lau.D. (1985). Internal Stability of granular

filters.

Canadian Geotechnical Jornal

Volume 22:215-225.

5) Mukunoki, T., Otani, J. & Kuwano, R. (2007).

Visualization

of cavity generation in soils on sewerage defects using X-ray

CT,

Proc. of the 13th Asian Regional Conference on Soil

Mechanics and Geotechnical Engineering, Kolkata,

India, :485-488.

Figure 11.Cumulative ratio of soil loss in each water

<Side wall >

Figure 12. Evaluation of loosening

60 40 20 0 20 40 60 (mm)

80

60

40

20

0

FIGURE 13. Measurement of loosening and cavity by CT scanner,

Mukunoki et al.(2007)

5)

)

<NATURAL >

<TOYOURA>

60 40 20 0 20 40 60

80

60

40

20

0

(mm)

CT-Value

0 100 200 300 400 500