1768

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

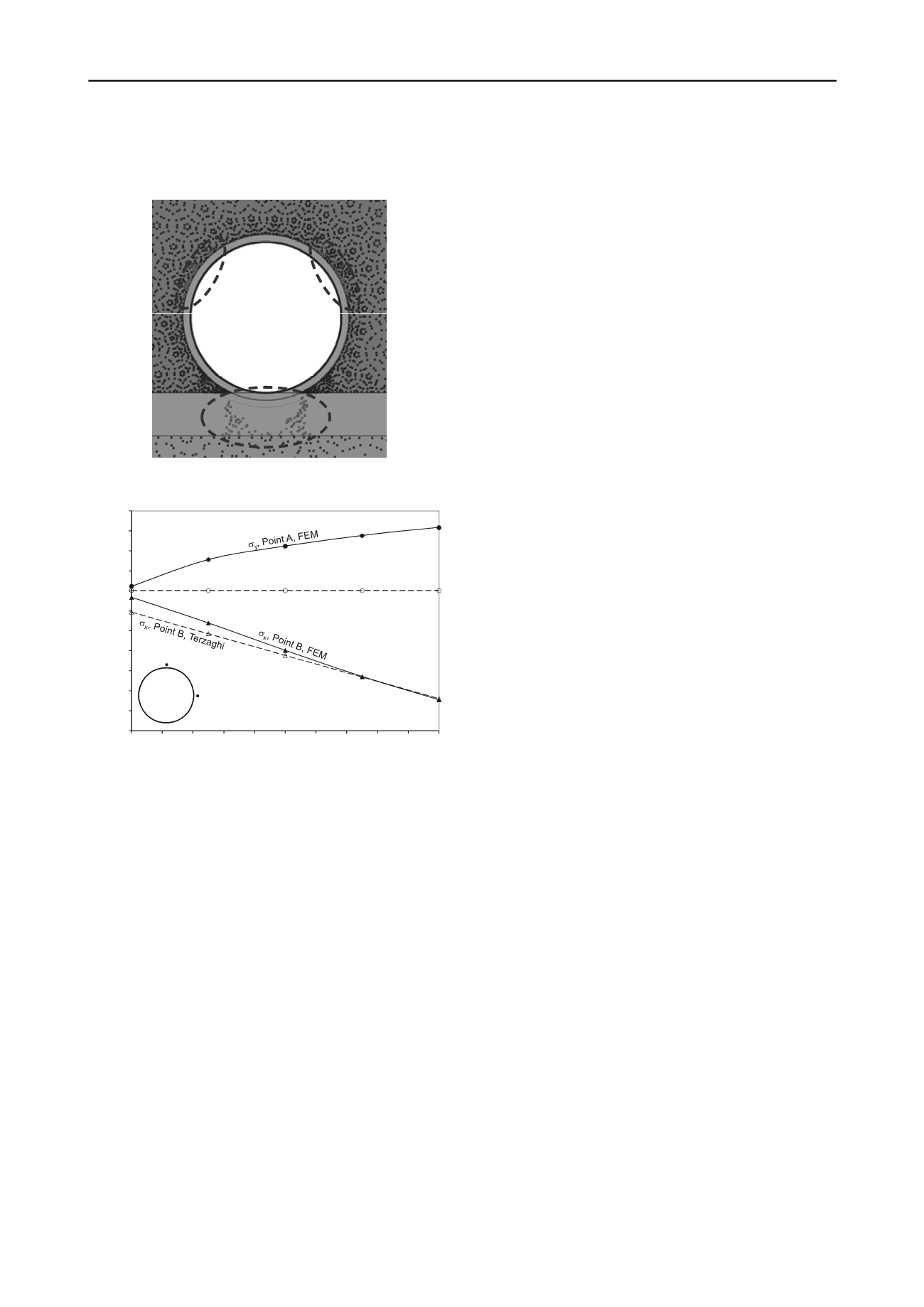

explained by the fact that the FEM takes into account the

interaction liner-soil that develops both during the construction

and serviceability stages.

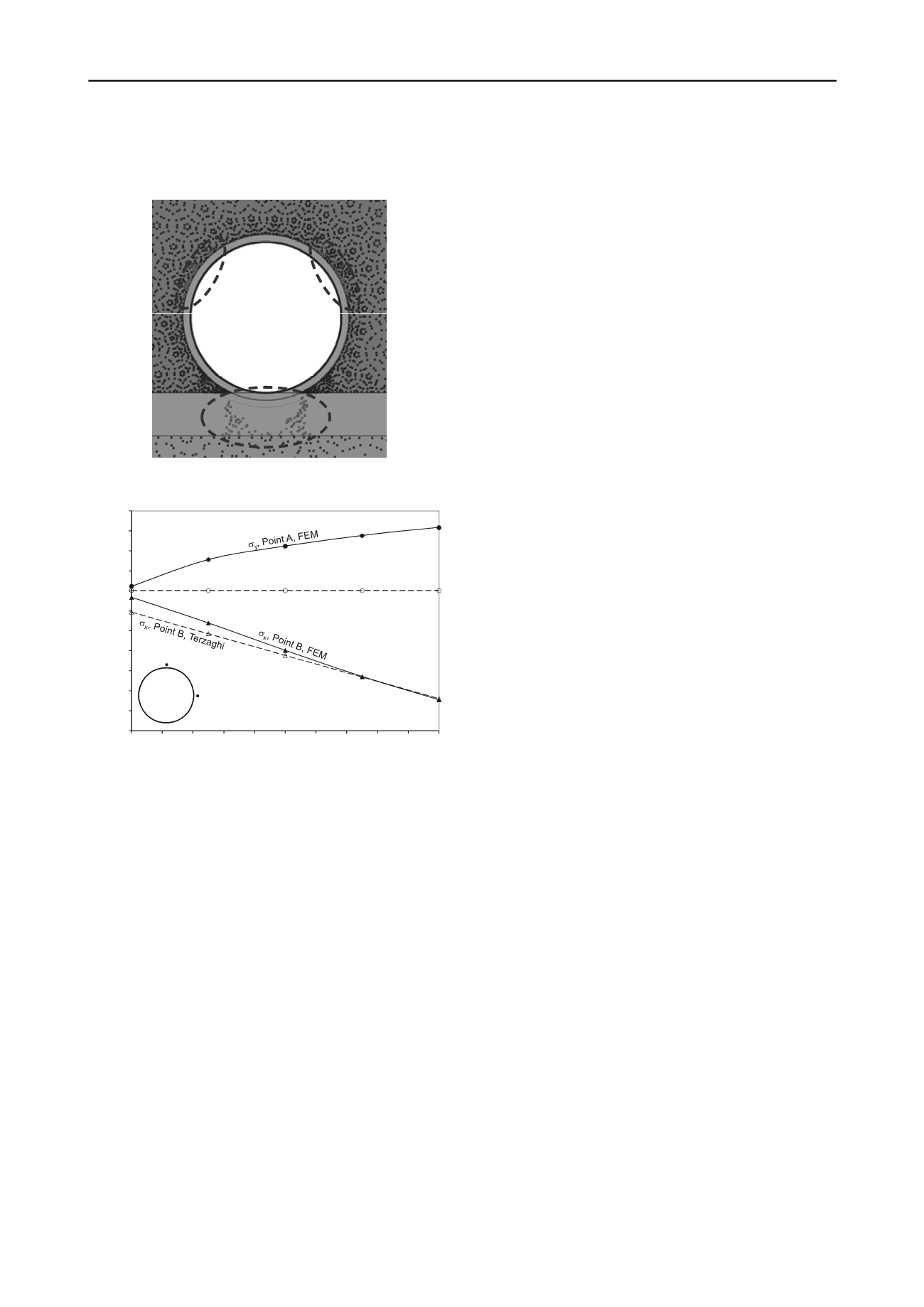

Figure 6. Stage 4, plastic stress point

70

90

110

130

150

170

190

210

230

250

270

290

0 10 20 30 40 50 60 70 80 90 100

Esfuerzo total, kPa

Abatimiento considerado, %

A

B

Tunnel

y

, Point A, Terzaghi

Total stress, kPa

Piezometric drawdown, %

Figure 7. Variation of total stresses with piezometric drawdown

4 CONCLUSIONS

A detailed description of the methodology employed for the

analysis and design of the definitive liner of a tunnel that will be

part of the Mexico City drainage system has been presented.

Part of this tunnel crosses through the clayey soils of the lake

zone in Mexico City valley.

It has been shown that unloading associated to the removal

of excavated soil produces a general upward movement of the

tunnel (“bubble” effect). As the excess of pore pressure

dissipates, a decrement of the effective stresses in the soil

located underneath the tunnel is produced. The stress decrement

originates that the clayey soil in such zone is transformed in a

pre-consolidated material, which becomes less compressible

that the surrounding zone. Because of this, as the definitive liner

is placed and the excess of pore pressure generated by the

piezometric drawdown dissipates, the soil below the tunnel

settles down at a lower rate than the surrounding soil. Therefore,

the tunnel experiences an apparent emersion with respect to the

surrounding media.

It was observed as well that during the piezometric

drawdown process, the secondary liner will be subjected to a

very unfavourable loading condition from a structural point of

view. Indeed, the upper part of the tunnel is submitted to a load

increment generated by the apparent emersion of the tunnel, and

at the same time, the sides of the tunnel experience a loss of

confinement due to a reduction of water pressure. The

unloading process developed on the sides of the tunnel can be

estimated using Terzaghi’s effective stress principle.

It has been confirmed that the FEM is a powerful tool for

analysing and designing tunnels in those difficult conditions,

since it allows: 1) considering different constitutive laws for the

materials involved; 2) simulating the phenomenon of

consolidation of the medium, due to excavation and

construction of the tunnel and piezometric drawdown and 3)

considering the interaction between liners and soil.

5 ACKNOWLEDGEMENT

These analyses were performed as part of the consulting

services provided by the authors to CONAGUA (water

authority in Mexico) for the design of “Túnel Emisor Oriente”

being built in Mexico Valley.

6 REFERENCES

Alberro, J. (1983). "Presiones de roca en túneles e interacción roca-

revestimiento". Instituto de Ingeniería, UNAM.

Alberro, J. & Hernández, R. (1989). "Efecto del flujo de agua en el

contorno de túneles". Instituto de Ingeniería, UNAM, No. 517.

Auvinet, G. & Rodríguez-Rebolledo, J.F. (2010). "Analysis, design,

construction and behavior of underground structures". XXV

RNMSeIG, Vol. 1, Acapulco: 33-42.

Bobet, A. (2001). "Analytical solutions for shallow tunnels in saturated

ground". Journal of Engineering Mechanics, ASCE Vol. 127 (12):

1258–1266.

Curtis, D.J. (1976). "Discussion on the Circular Tunnel in Elastic

Ground". Géotechnique, Vol. 26, No. 1: 231-237.

Equihua, L.N. (2000). “Túneles en suelos blandos con hundimiento

regional”. MEng thesis, UNAM.

Farjeat, E. & Delgado, S. (1988). “Diseño de dovelas para túneles del

metro alojadas en arcillas compresibles de la Ciudad de México”.

Tunnels and Water, Serrando (ed), Balkema, Rotterdam: 117-135.

Flores, F.A. (2010). “Análisis del comportamiento estático de túneles

excavados en suelos blandos”. Tesis para obtener el grado de

Maestro en Ingeniería. Programa de Maestría y Doctorado en

Ingeniería, UNAM.

Kirsch (1898). "Die Theorie der Elastizität und die Bedürfnisse der

Festigkeitslehre". Zeitschrift des Vereines deutscher Ingenieure,

Vol. 42: 797–807.

Morgan, H. (1961). "A contribution to the analysis of stress in a circular

tunnel". Géotechnique, Vol. 11: 37-46.

Wood, M. (1975). The circular tunnel in elastic ground. Géotechnique,

No. 1, pp 115-127.

Zaldívar, S.F., Rodríguez-Rebolledo, J.F. & Auvinet, G. (2012). “Stress

and displacements distribution around a tunnel taking into account

the "bubble effect"”, 2º Simposio Internacional sobre túneles y

lumbreras en suelos y roca, Mexico City.