1181

Technical Committee 106 /

Comité technique 106

obtained in the compaction test, such as material A, the decay of

structure and loss of overconsolidation are fast. On the other

hand, in the case of materials for which a small maximum dry

density was obtained in the compaction test, such as material C,

there was little decay of structure, and loss of overconsolidation

was moderate. Finally, for material B, the results indicated that

the decay of structure was fast and that the loss of

overconsolidation was slow. As the maximum dry density

increased, decay of structure occurred faster. However, there

was no correlation between the rate of loss of overconsolidation

and the maximum dry density. Also, focusing on the initial

values, for all materials, it can be seen that as the Dc increased,

the structure decayed, and overconsolidation accumulated. Also,

it can be seen that for material such as C with small maximum

dry densities, structure and overconsolidation tend to remain

even though they are compacted. It can be inferred that this is

because there is little decay of structure due to shearing. Also,

focusing on materials A and B at Dc of 95–100%,

overconsolidation increases suddenly as a result of compaction.

At this time, the

q

also increases greatly. It can be seen that the

increase in

q

of compacted soil can be determined by the ease of

accumulation of overconsolidation.

Table 2 Material constants

Material

A

B

C

Elasto-plastic parameters

Compression index

0.07

0.11

0.13

Swelling index

0.01

0.02

0.01

Limit state index

1.48

1.35

1.45

NCL intercept (98.1 kPa)

1.50

1.71

2.07

Poisson’s ratio

0.30

0.30

0.30

Normal consolidation index

5.00

0.50

1.30

Evolution rule parameters

a

10.0

2.00

0.80

b

1.00

1.00

1.00

c

1.00

1.00

1.00

Structure decay index

s

c

1.00

1.00

0.40

Rotational hardening index

0.00

0.10

0.00

Rotational hardening limit constant

0.10

0.40

1.00

Table 3 Initial values

Material

Dc

Specific

volume

Extent of

structure Overconsolidation

90

1.55

1.50

3.77

95

1.47

1.30

13.2

A

100 1.40

1.10

32.0

90

1.72

1.30

8.10

95

1.64

1.20

19.1

B

100 1.56

1.10

42.5

90

2.17

2.20

5.1

95

2.08

1.90

9.8

C

100 1.98

1.40

16.2

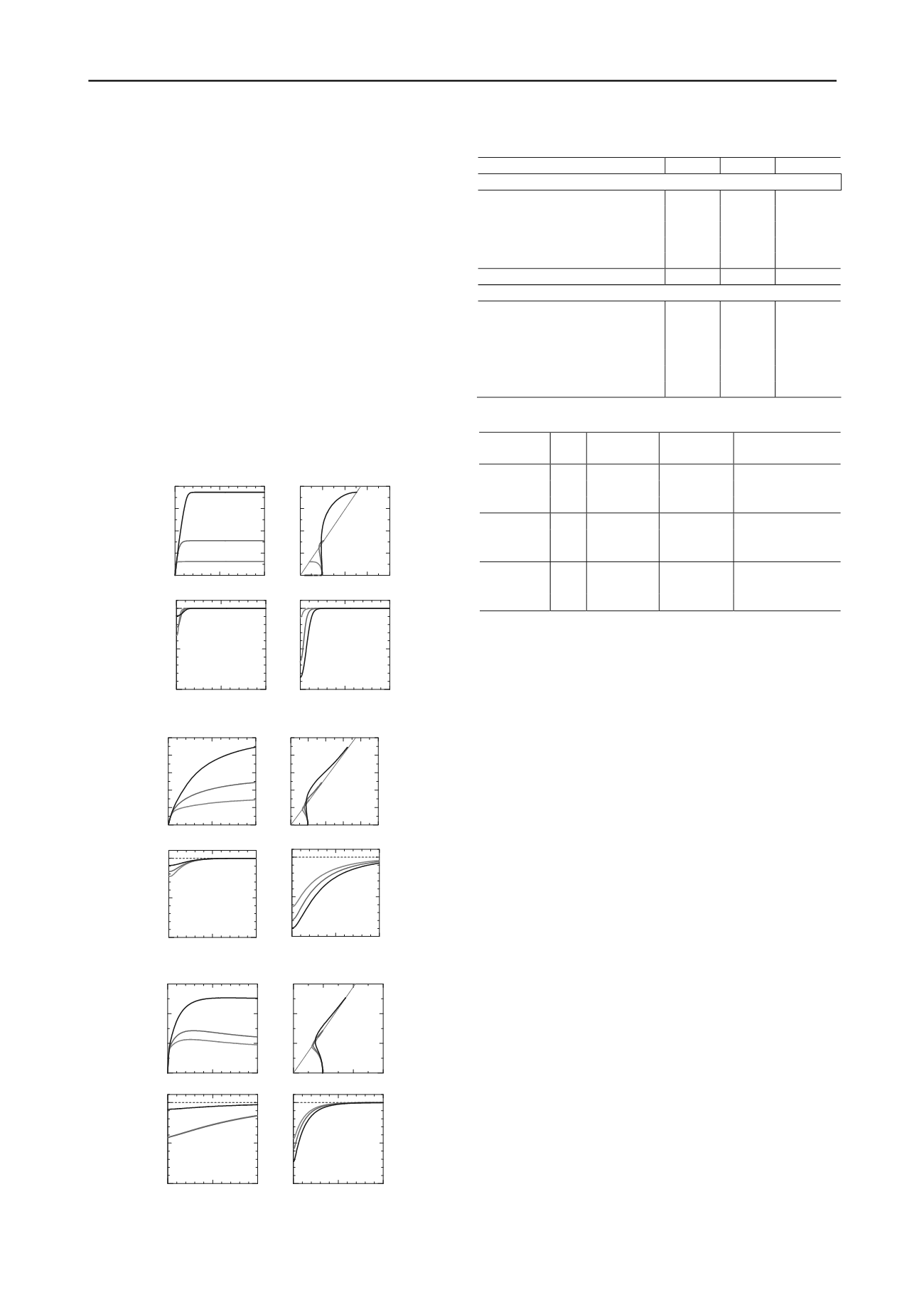

0

10

20

200

400

0

200

400

200

400

Shear strain

s

(%)

Deviator stress

q

(kPa)

Mean effective stress

p

(kPa)

Deviator stress

q

(kPa)

q =

M

p

0

10

20

0.5

1.0

Shear strain

s

(%)

R*

Decay of structure

very fast

Loss of

overconsolidation

very fast

0

10

20

0.5

1.0

Shear strain

s

(%)

R

5 SEISMIC RESPONSE ANALYSIS OF EMBANKMENTS

Fig. 7 shows a complete cross-section of the embankment and

ground used in the analysis. The ground was assumed to be hard

ground with poor permeability. Also, it was made sufficiently

wide to take into consideration the effects of the side surface

boundaries. The height of the embankment was 6 m, with slopes

of 1:1.8. Also, the width of the crown was 14 m, assuming an

expressway with one lane on each side. The hydraulic boundary

conditions were as shown in Fig. 7; the edges on the left, right

and bottom were impermeable boundaries, and the top edge was

a permeable boundary (atmosphere). Also, the water level was

always constant at the ground surface. In other words, the

ground and embankment were always saturated. The movement

boundary conditions before the earthquake were as follows: all

the nodes on the left and right edges were fixed horizontally,

and all the nodes on the bottom surface were fixed horizontally

and vertically. During and after the earthquake, periodic

boundaries were assumed, and both edges were provided with

constant displacement boundaries. In addition, in order to

prevent all reflections of the seismic waves, a viscous boundary

(Joyner et al. 1975) was provided in the horizontal direction on

the bottom edge during the earthquake. The seismic motion is

measured ground surface wave at Kobe Marine Observatory in

the Southern Hyogo prefecture earthquake in 1995. The input

seismic motion was assumed to be a level 2 inland earthquake.

In this section, the materials analyzed were materials A and C.

Figure 4. Material A reproduction results

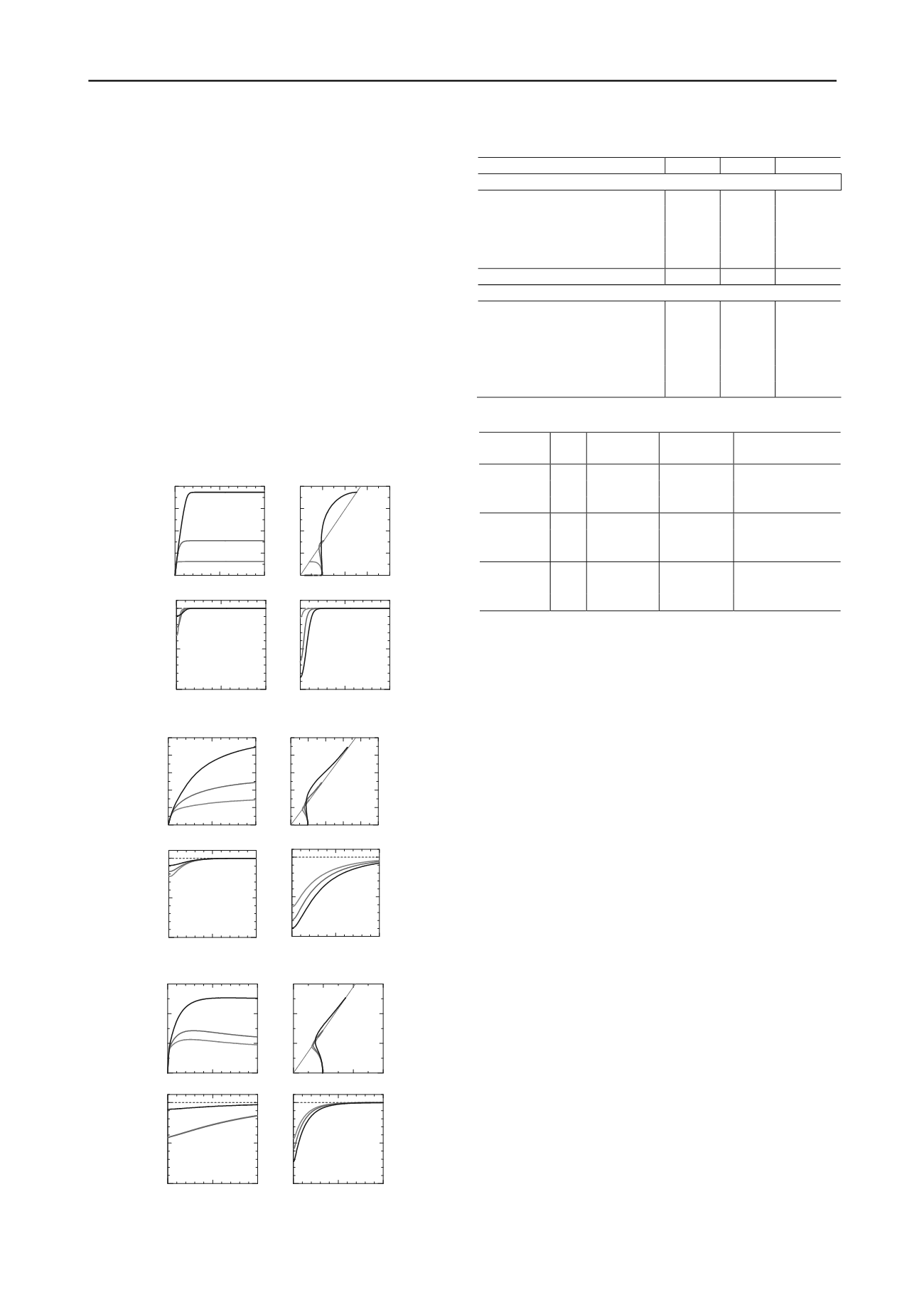

0

10

20

200

400

0

200

400

200

400

Shear strain

s

(%)

Deviator stress

q

(kPa)

Mean effective stress

p

(kPa)

Deviator stress

q

(kPa)

q =

M

p

0

10

20

0.5

1.0

Shear strain

s

(%)

R

0

10

20

0.5

1.0

Shear strain

s

(%)

R*

Decay of structure

fast

Loss of

overconsolidation

slow

Figure 5. Material B reproduction results

0

10

20

100

200

300

0

100 200 300

100

200

300

Shear strain

s

(%)

Deviator stress

q

(kPa)

Mean effective stress

p

(kPa)

Deviator stress

q

(kPa)

q =

M

p

0

10

Figs. 8 and 9 show the shear strain distribution immediately

before and after the earthquake for materials A and C,

respectively. Also, the values shown in the figures indicate the

amount of settlement in the center of the crown after the

earthquake. For all the materials, as the Dc is increased, the

strain due to the earthquake becomes smaller, and the amount of

settlement is reduced to about one-third. It can be seen that

increasing the Dc is extremely effective for improving the

seismic stability of embankments. For material A at all Dc, the

strain due to the earthquake did not extend, and stable behavior

20

0.5

1.0

Shear strain

s

(%)

R

0

10

20

0.5

1.0

Shear strain

s

(%)

R*

Decay of

structure slow

Loss of

overconsolidation

fast

Figure 6. Material B reproduction results