1172

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

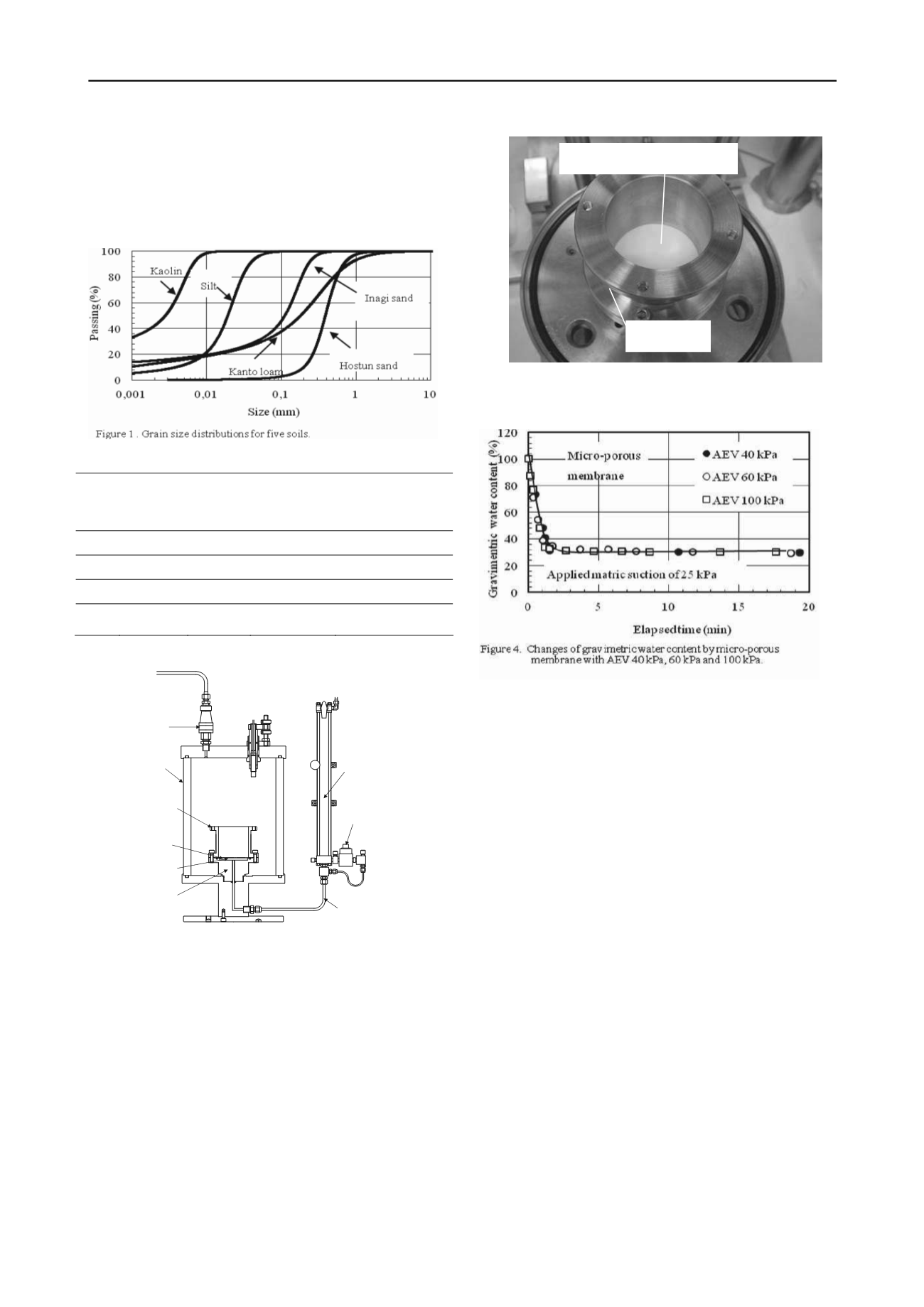

manufactured by Pall. Corporation (

. Two

different types of membranes (i.e., polyether sulfone and acrylic

copolymer) were used in this testing program as summarized in

Table 1. The air entry values of the membranes range from 40

kPa to 250 kPa depending on the pore size and manufacturing

process.

Table 1. Micro-porous membranes used in the test program.

No

Thickness

(μm)

Air entry

value

(kPa)

Pore

diameter(μm)

Material

1

140

250

0.45

Polythersulfone

2

140

100

0.8

Polyther sulfone

3

94

60

0.8

Acrylic copolymer

4

94

40

1.2

Acrylic copolymer

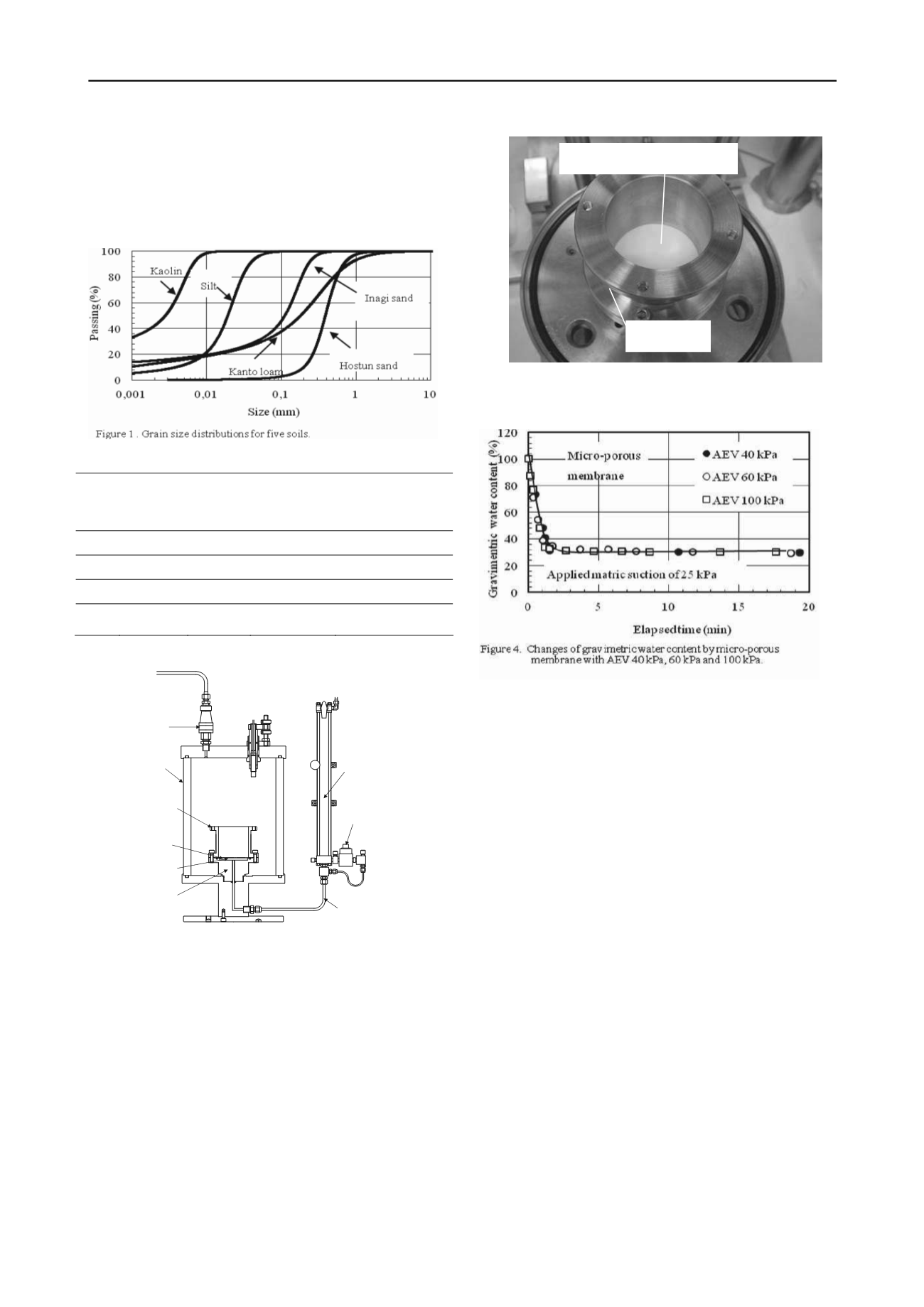

Figure 2. Illustration of the modified SWCC apparatus.

2.2 Modified SWCC apparatus with micro-porous

membrane

The study utilized the new soil-water characteristic curve

apparatus (i.e., SWCC apparatus) as shown in Fig. 2. The

modified SWCC apparatus consisted mainly of a pedestal, a

steel mold, a triaxial chamber and a double glass burette

connected to a differential pressure transducer. Fig. 3 shows the

saturated micro-porous membrane in the steel mold. The steel

mold has an inside diameter of 60 mm and a height of 65 mm.

The pedestal was attached to the triaxial base plate. The water

compartment was connected to the base of the triaxial cell and

the double glass burette. Soil water was allowed to flow into

the double glass burette. A differential pressure transducer was

attached to the lower portion of the double glass burette

Micro-porous membrane

.

A pressure plate apparatus with a ceramic disk was used to

compare the results with those obtained from using the new

micro-porous membrane apparatus. The high air entry ceramic

disk was installed into the pedestal in place of the micro-porous

membrane. The ceramic disk had a thickness of 7 mm and an

air entry value of 200kPa or 500 kPa.

2.3 Soil-water characteristic curve, SWCC, tests

Soil-water characteristic curve tests were performed in the low

matric suction range with a maximum matric suction of 20 kPa.

Drying and wetting paths were established by progressively

increasing and decreasing matric suction. The soils were

prepared in a slurry condition at a high gravimetric water

content. Soil water moved in response to the externally applied

air pressure and accumulated in the burette with elapsed time.

The gravimetric water content of the soil specimen was

calculated from the changes in the amount of water in the soil.

When the water level in the burette attained a steady state

condition, it was assumed that equilibrium conditions have been

attained with regard to the applied matric suction. As a result,

the air pressure supplied to the triaxial chamber was equal to the

matric suction in the soil specimen. The matric suction was

progressively increased up to about 20 kPa. After the

application of the applied maximum matric suction, the air

pressure in the chamber was decreased following the path of

decreasing matric suction.

Steel mold

Figure 3. Assembly steel mold with developed pedestal.

Acrylic cell

Steel mold

Micro-porous

membrane

Difference pressur

sensor

Double glass

burette

Air supply air

pressure

Pedestal

Porous stone

Water tube leading

e