1165

Technical Committee 106 /

Comité technique 106

point was 0.65 for Case 1 and 0.67 for Case 2. The saturation

degree of LNAPL was measured from the injection volume

when we observed the LNAPL in the plate at the outlet position.

Values were 80.1% for Case 1 and 83.1% for Case 2. These

similar values indicate that the prepared samples both had

similar pore structures at the initial condition.

3.2

KI solution injection into sand polluted by LNAPL

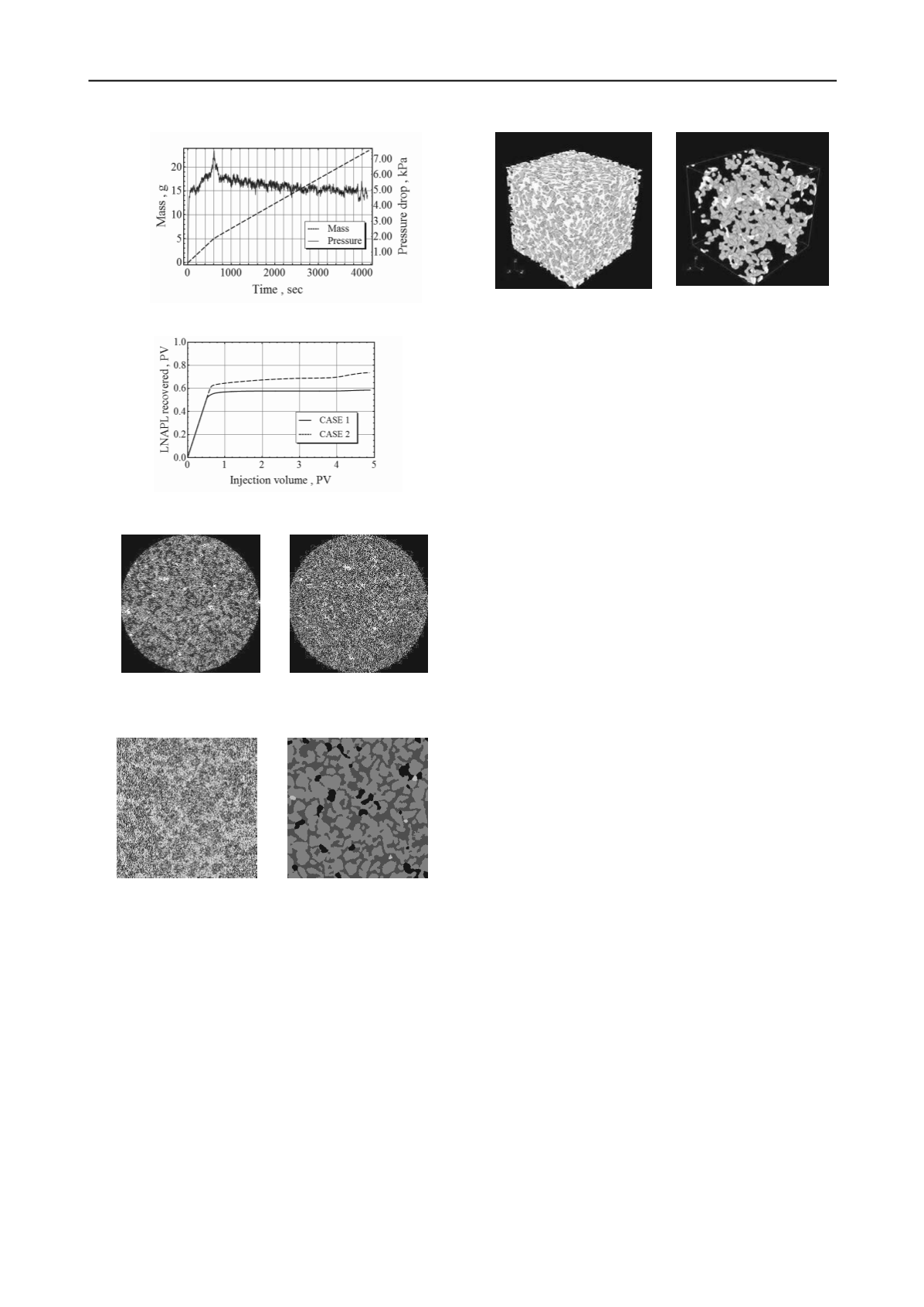

Figure 6 shows the volume profile of LNAPL recovered by KI

solution injection. As shown in Figure 6, the injection pore

volume at the breakthrough point was 0.51 for Case 1 and 0.56

for Case 2, indicating that the entry pressure for Case 1 was

observed earlier than Case 2. To evaluate this phenomenon, the

capillary number may help in the following equation (1):

Ca

= v

w

dal

w

/

where

v

dal

is Darcy’s velocity,

is kinematic viscosity, and

is

the interfacial tension. Subscript w

means “wetting.” The

capillary number

Ca

indicates the ratio of viscosity and

interfacial tension

,

and when

Ca

is less than 10

-6

multiphase

flow should be dominated by capillary pressure (Mayer &

Miller, 1993). In other words, a low

Ca

number may cause

fingering flow in porous media. In this study,

Ca

for Case 1 was

1.57 x 10

-6

and

Ca

for Case 2 was 3.14 x 10

-5

. LNAPL

saturation degrees after the KI solution injection test in Case 1

and Case 2 were 21.5% and 9.5%, respectively, confirming that

Ca

greater than 10

-6

caused less volume of residual LNAPL.

3.3

Evaluation of pore structure using the MCW method

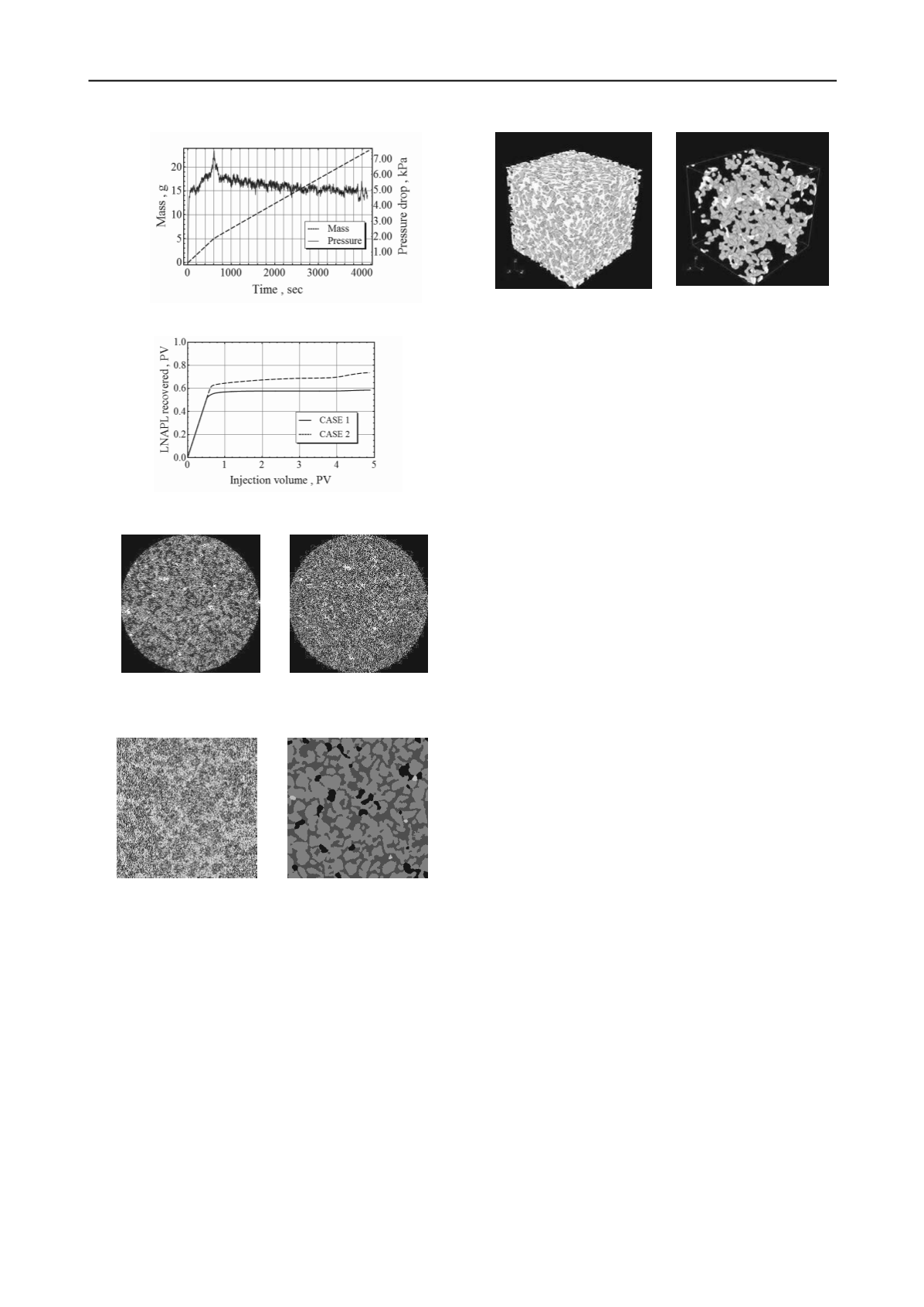

Figure 7 shows MXCT images of sand after injecting LNAPL

(Figure 7(a)) and KI solution (Figure 7(b)) in Case 1. X-ray CT

images are generally 256-level grayscale, with black areas

having the least density and white areas the greatest. Figure 7(a)

shows that LNAPL was trapped, and its shape was different.

Also, the black shape of LNAPL in Figure 7(b) was more

circular than as seen in Fig 7(a). These LNAPL blobs are

residual LNAPL trapped due to KI solution injecting. Multi-

threshold processing with the MCW method was applied to a

CT image with 512 × 512 × 512 cubic voxel area. The 4-color

MXCT image shown in Figure 8(b) was created from Figure

8(a).

Based on 4-color CT images, only pore structure and residual

LNAPL could be extracted from the CT images in Figure 8(b).

The porosity obtained from 3D CT images was 40.7% for Case

1 and 38.5% for Case 2. In fact, the porosity calculated from the

mean dry density of the sand sample was 39.4%, and the

difference should be negligible (<1% error), confirming that

multi-threshold processing with MCW gave reasonable values

for porosity. Residual LNAPL after injecting the KI solution

was 16.7% for Case 1 and 12.6% for Case 2. Measured

saturation of residual LNAPL from the mass in the outlet plate

was 4.8% less than the obtained value from MCW for Case 1,

and 3.1 % greater than that for Case 2.

Figures 9(a) and 9(b) show 3D CT images of pore structure

and LNAPL blobs isolated with MCW processing. Pore

structure and LNAPL blobs were thus successfully extracted

from soil samples in three dimensions without disturbance.

3.4

Cluster analysis of pore structure

Figures 10 shows histograms of pore size in Case 1 and Case 2.

Frequency in vertical axis means the normalized value by total

voxel number of pore structure. Maximum pore size in Case 2

was slightly greater than in Case 1, as shown in Figure 10.

There were 1317 pore elements with LNAPL in Case 1 and

1023 in Case 2. Table 3 summarizes saturation degrees of

LNAPL for Case1 and Case 2 before and after KI solution

injecting obtained from X-ray CT images treating MCW

processing. Initially, the sand sample for Case2 had only 3%

greater saturation degree of LNAPL than Case 1. However,

residual saturation degree of LNAPL for Case 2 was less than

(a)

LNAPL injecti

on under KI

saturation conditions

(b) KI solution

injection after

the status of Fig. 7(a)

(

b) Partial MXCT image

after MCW processing

(

a) Partial MXCT image

before MCW processing

Figure 6. Volume profile of LNAPL recovered in Cases 1

and Case 2

Figure 7. MXCT images after injecting LNAPL and KI

solution

(a) Pore structure

(b) Residual LNAPL distribution

Figure 5. Pressure difference between inlet and outlet

and cumulative fluid mass in Case 1

Figure 8. MXCT images after MCW processing

Figure 9. MXCT images after MCW processing