1164

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

isoparaffin, which has a fluid density of 0.75 g/cm

3

. Figure 2

shows the MXCT experimental setup, and Table 2 shows the

scanning conditions.

2 IMAGE PROCESSING ANALYSIS

2.1

Marker-controlled watershed processing

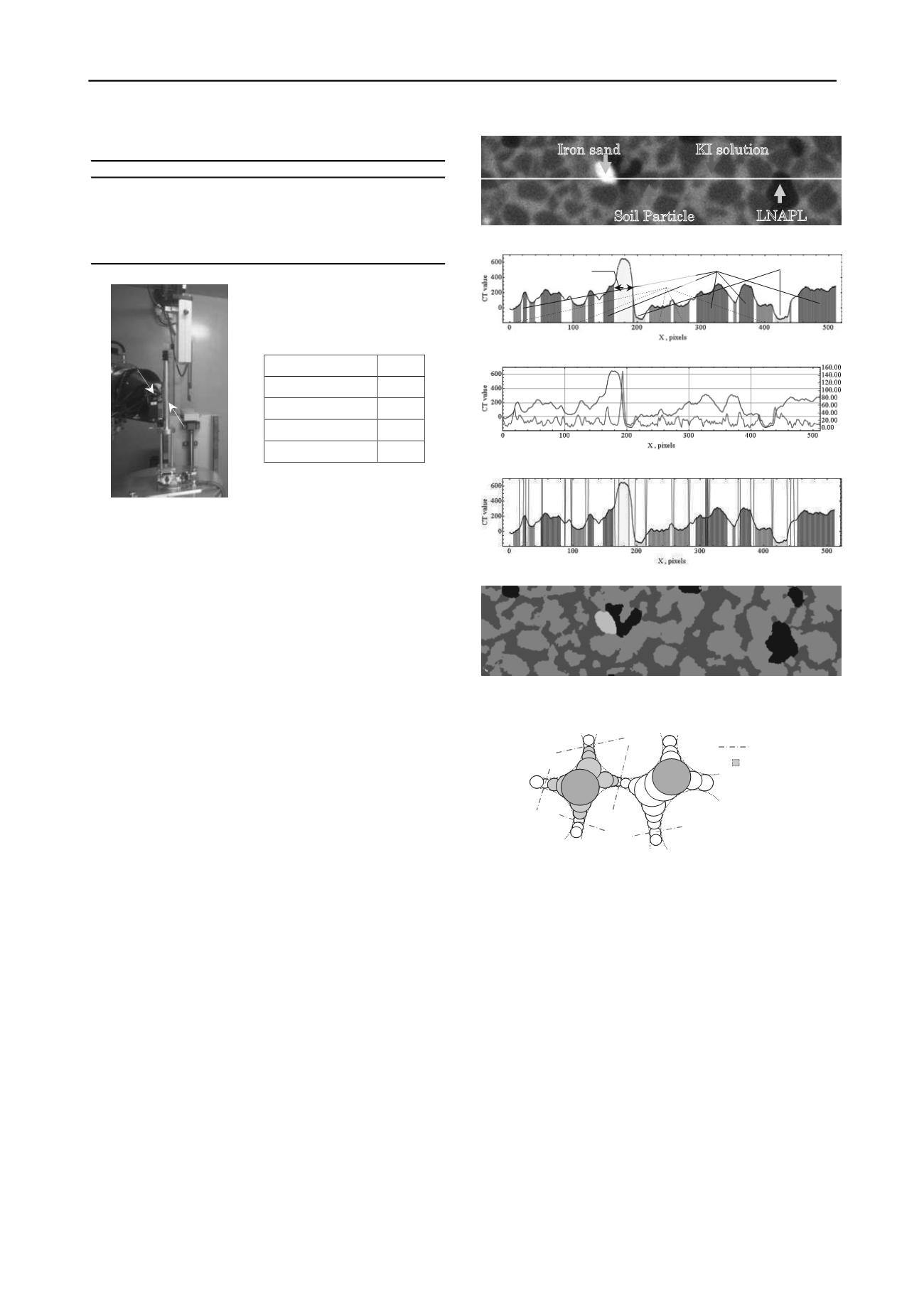

X-ray CT images are composed of voxels, called CT-values,

which are proportional to the material density. To separate pore

space and soil particles in the image, it is necessary to define a

threshold value for the CT values. Figure 3 shows an X-ray CT

image of Toyoura sand that includes KI solution and LNAPL.

That image also includes magnetic sand, so four kinds of CT-

value exist in the CT image of Figure 3(a): soil particles, solid-

phase magnetic sand particles, KI solution, and liquid-phase

LNAPL. Knowing the number of materials in the CT images

allows fixing areas of magnetic sand particles, soil particles,

LNAPL, and pore space, as well as identifying mixels where

two or more materials occupied a single voxel. Watershed

processing, which is based on CT-value gradient changes

between materials, was applied only to mixel areas in what is

called the marker-controlled watershed (MCW) method. Figures

3(b)

–

(d) show the MCW process. Figure 3(b) is the CT-value

profile obtained from lines in the CT image in Figure 3(a).

Clarification of the materials in the CT image allows defining

the CT-value range for each material without knowing CT-

values for the mixel. To evaluate the gradient in the mixel areas,

Figure 3(c) shows a profile of the gradient obtained from Figure

3(b). Finally, the coordinate in the CT image with maximum

gradient was defined between different materials, and watershed

processing was applied to the CT image. This CT-value

thresholding technique does not lose spatial geometry

information, and is an objective approach for distinguishing the

CT threshold values.

2.2

Image analysis technique for connectivity of pore

structure based on mathematical morphology

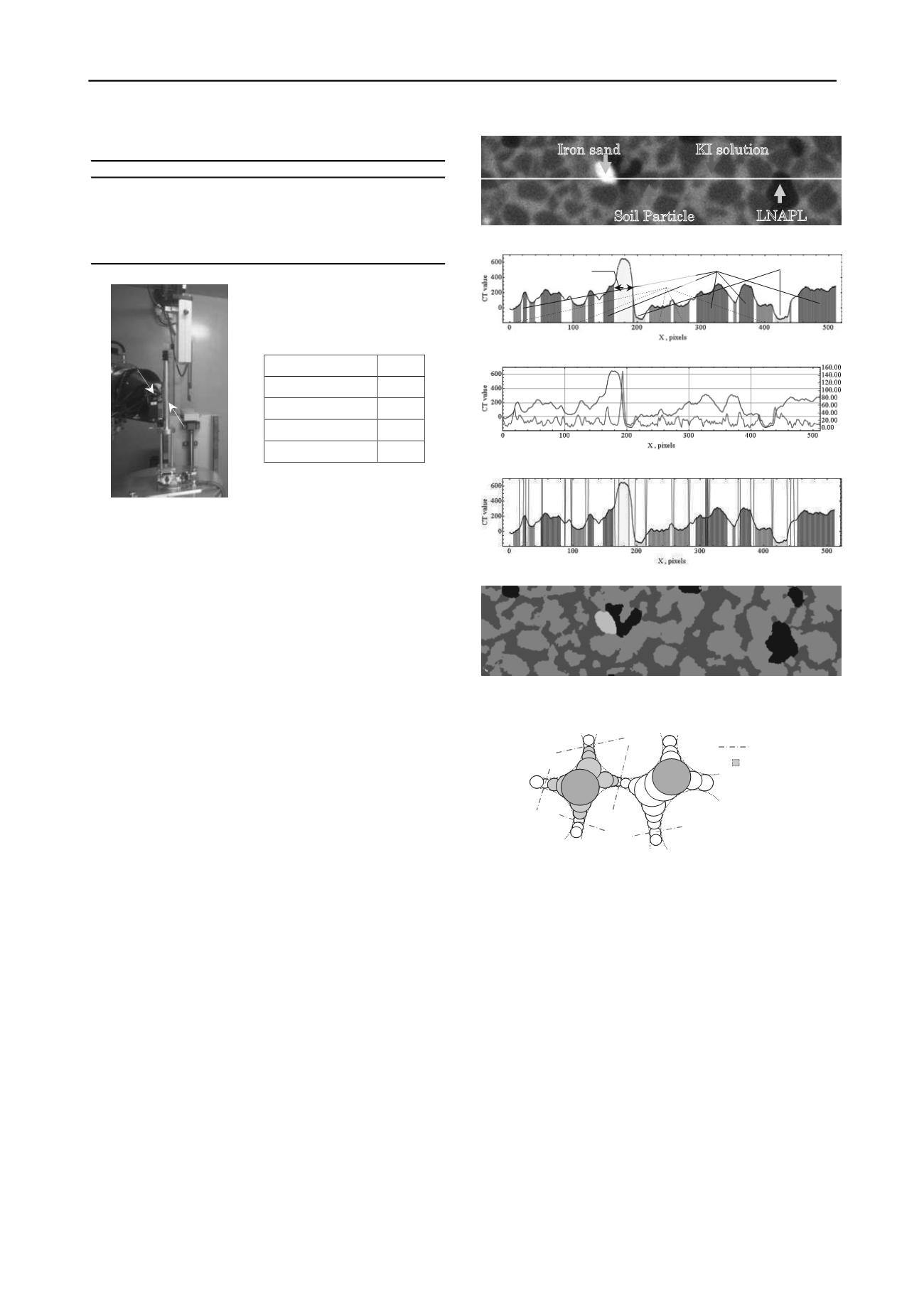

Mukunoki et al. (2011) proposed an image processing technique

that uses mathematical morphology (Soille, 2002) to evaluate

the 3-D distribution of pore scale in dry, sandy soil (a two-phase

soil particle and air mixture). We used this method to evaluate

the volume and diameter of pore water, and showed that

LNAPL existed in pore structures. Moreover, connectivity of

the pore structure affects flow behavior, and so should be

considered in this study. If continuous structures could be

isolated as part of a pore structure, a cluster labeling method

would give the number of isolated LNAPL blobs and their

connectivity. The authors applied the evaluation method of the

3D distribution of pore scale, and used this method to find a

circle with minimum diameter as shown in Figure 4. This

method successfully separated entire pore structures, making it

possible to evaluate spatial distribution of the LNAPL volume

.

3 RESULTS AND DISCUSSION

3.1

LNAPL injection to the sand with saturation of 100%

Intrinsic permeability (k) of the tested sand was 1.75 × 10

-11

m

2

for Case 1 and 1.57 × 10

-11

m

2

for Case 2, as obtained from the

injection test. In this study, the injection speed was a parameter

for this test. Figure 5 shows the difference between inlet and

outlet pressures, and the mass of fluid collected at the outlet for

Case 1. The injection pore volume (PV) at the break-through

Core

Core

Watershed

element

Iron sand

Soil Particle

LNAPL

KI solution

KI solution LNAPL

Iron sand

Soil

(a) Partial CT image

(b) Selection of marked area in the CT-value profile

(c) Extraction of gradient in the CT-value profile

(d) Definition of marked areas in the CT-value profile

(

e) X-ray CT image treated with MCW processing

Table 2. Scan conditions

Voltage (kV)

180

Current (μA)

200

Number of view angles

1500

Projection average

10

Resolution (μm)

5

Property

LNAPL KI solution

density

ρ

(g/cm

3

)

0.7486

1.24786

viscosity

ν

(cP)

1.29

0.9664

Surface tension

γ

(dyn/cm)

20.0

72.3

contact angle

• •

(degree)

6.4

62.1

interfacial tension

γ

nw

(dyn/cm)

54.5

MOLD-STORE SAMPLE

X-RAY TUBE

Figure 3. Marker-controlled watershed processing

Figure 4. Schematic of analysis method

Table 1. Specification of fluids tested

Figure 2. A photograph

of scene before CT

scanning