1156

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The SWRC is dependent on various physical, chemical,

mineralogical and mechanical properties. One factor that

influences the SWRC is the initial water content. Many studies

have been put forward in recent years on the effect of the initial

water content on SWRC, mainly considering SWRCs following

drying paths. Vanapalli et al. (1999) observed the influence of

compaction in soil samples at different levels (at optimum, wet

and dry of optimum water contents). Where, the SWRC

following a drying path was determined for samples dry of

optimum, it was found to be steeper than the SWRC at optimum

or wet of optimum. The attributed reason was that the samples

tested dry of optimum have a highly aggregated macro

structure, thus resembled the behaviour of coarser material.

However, the micro structure governs the SWRC wet of

optimum (as soils are unlikely to be aggregated in this

condition). It has been observed that at high suctions all SWRCs

seem to converge to a single curve. Studies have been

conducted by Marinho and Chandler (1993), Ng and Pang

(2000), Birle et al. (2008), among others, that have shown that

the SWRCs are greatly influenced by the initial water content.

In this paper a series of suction measurements using filter

paper tests is presented that were carried out on remoulded

samples of a sandy clay soil. Soil samples were prepared with

different initial water contents (10%, 13%, 15%, 20% and 22%)

and dynamically compacted that were then used to perform the

filter paper tests. Other samples were wetted or dried to reach

the other water contents for testing. The results obtained were

then compared with the soil water retention curve (SWRC) for

this material drying from a saturated state.

2 MATERIALS AND METHODS

2.1

Material properties

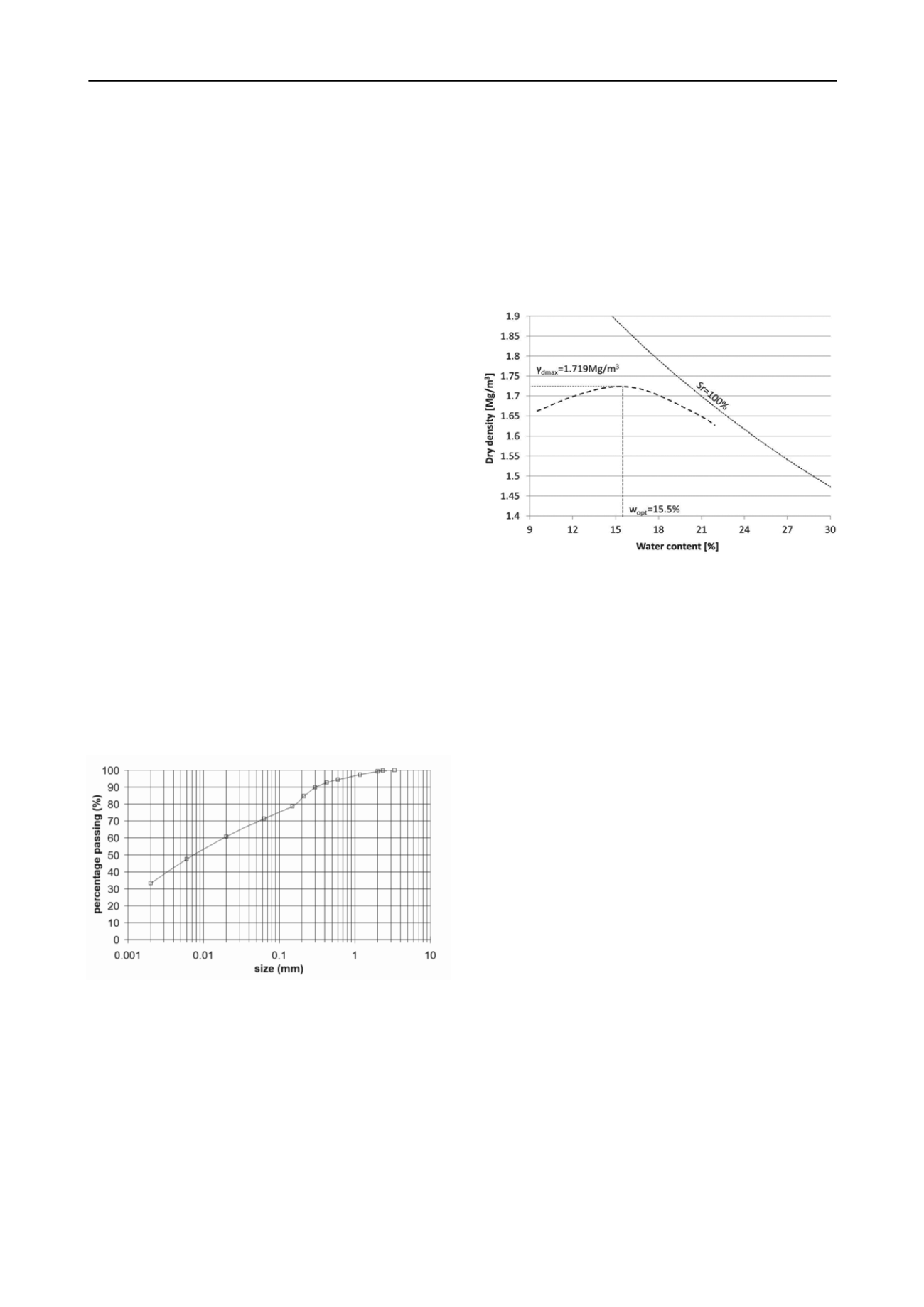

The soil material used in this study was glacial till sourced from

a stock pile in County Durham, UK. From the particle size

distribution shown in Figure 2, the soil material is classified as

well graded sandy clay. As for the index properties, the liquid

and plastic limits were found to be 43.3% and 23.7%

respectively, meaning a plasticity index of 19.6.

Figure 2. Particle size distribution curve of the sieved material.

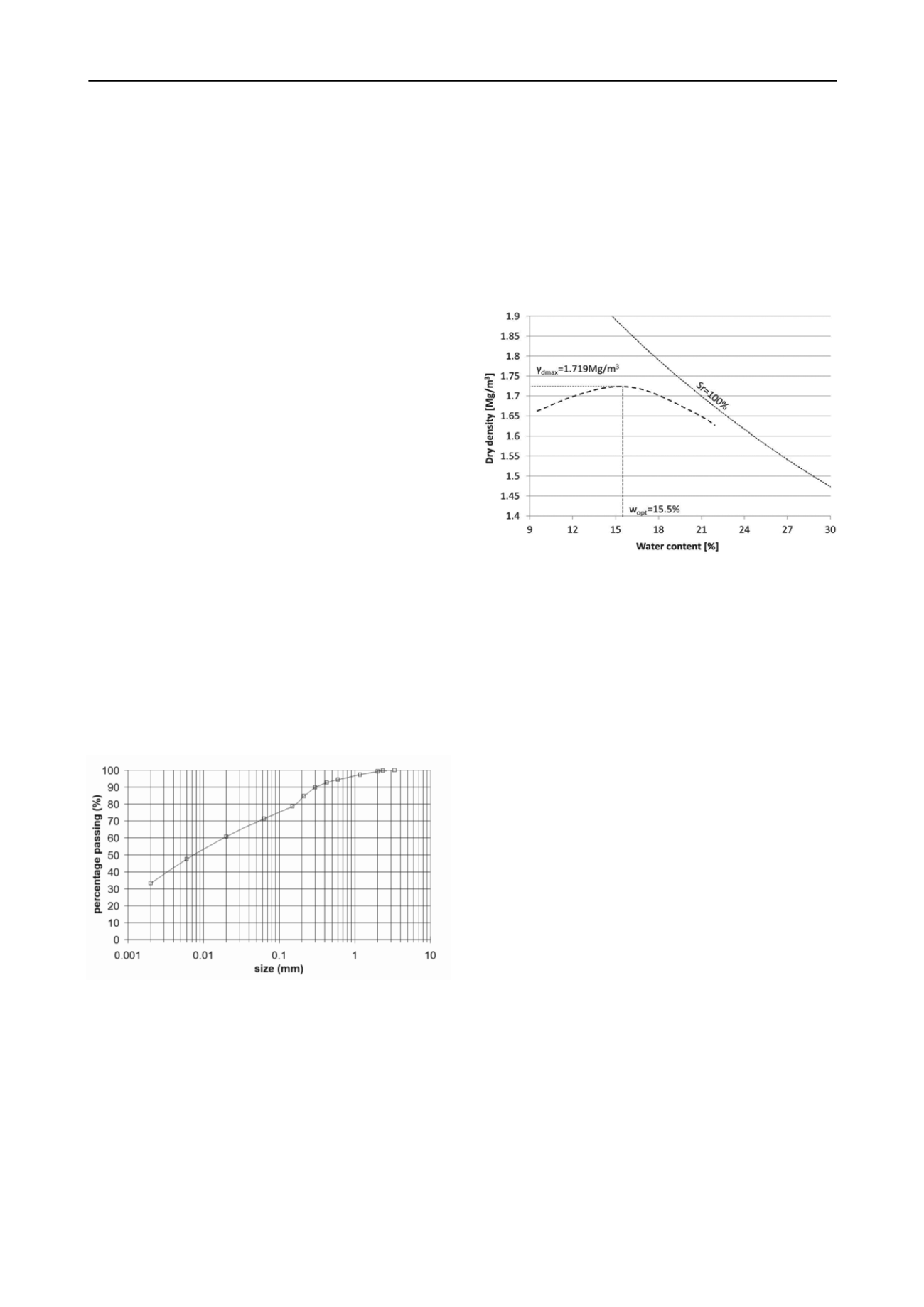

Due to the variability in sample preparation, observed in

preliminary tests, the soil material was sieved to a maximum

particle size of 2.80mm to remove occasional gravel sized

particles. The resulting compaction curve is shown in Figure 3,

where the optimum water content was found to be 15.5% at a

maximum dry density of 1.719Mg/m

3

.

2.2

Sample preparation

Samples with size 100mm in diameter and 200mm in height

were dynamically compacted after preparation at 5 different

water contents: 10%, 13%, 15%, 20% and 22%. Subsequently,

subsamples were trimmed down to discs with 55mm in diameter

and 20mm in height.

For testing purposes, discs with similar water content were

later dried or wetted to other water contents (e.g. subsamples at

an initial water content of 15% were dried to 10% or 13% and

wetted to 20% or 22%). The drying procedure used was air

drying, while the wetting procedure was conducted inside an

humidifying chamber. In both cases, after the subsamples had

reached the target water content, they were sealed off for a

period of at least 5 days for water content homogenization.

Detailed information on these procedures can be found in

Mendes (2011).

Figure 3. Compaction curve obtained for the sieved material.

2.3

Filter paper technique

The filter paper technique was used to determine the soil

suction. This technique can measure soil suction either by

vapour flow (non-contact filter paper – total suction) or by

liquid flow (contact filter paper – matric suction). This

measurement is achieved by letting the soil-filter paper system

to reach equilibrium. When this equilibrium is reached the

measurement of soil suction can be determined. The major

advantages of the filter paper technique are the wide measuring

range, from 0 up to 30MPa, and low cost. The major drawbacks,

however, are the long term equalization period (5 to 14 days)

and the quality of the measurement, which is dependent on the

experience of the user and also on the calibration curve that

relates the water content of the filter paper to suction.

The method for the filter paper technique used in this work

was adapted from Bulut et al. (2001) for the measurement of

soil matric suction. Three filter papers, in this case Whatman

42, were placed in intimate contact between two sample discs of

similar water content, as shown in Figure 4. The outermost filter

papers were used to prevent contamination from soil particles

and the middle filter paper was used for the measurement. The

whole setup, filter papers and disc samples, was sealed with

electrical tape to prevent contact between the filter papers and

air and placed inside a glass jar. The jar was later wrapped in

plastic film, coated in paraffin wax and submerged in a water

bath at 25

o

C for an equalization period of 14 days. After the

equalization period, both sample discs and filter paper were

quickly removed from the glass jar in order to determine the

filter papers’ wet mass to a level of accuracy of 0.0001g. These

were later oven dried for determination of the water content.

The water content of the filter paper was then used to determine

the corresponding suction, by means of a calibration curve,

associated with the known water content of the sample discs.

Based on the work of Noguchi et al. (2011) it was found

that the calibration curve that gave a best match for this

particular soil was that obtained by van Genuchten (1980) in the

form of equation (1).