1180

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

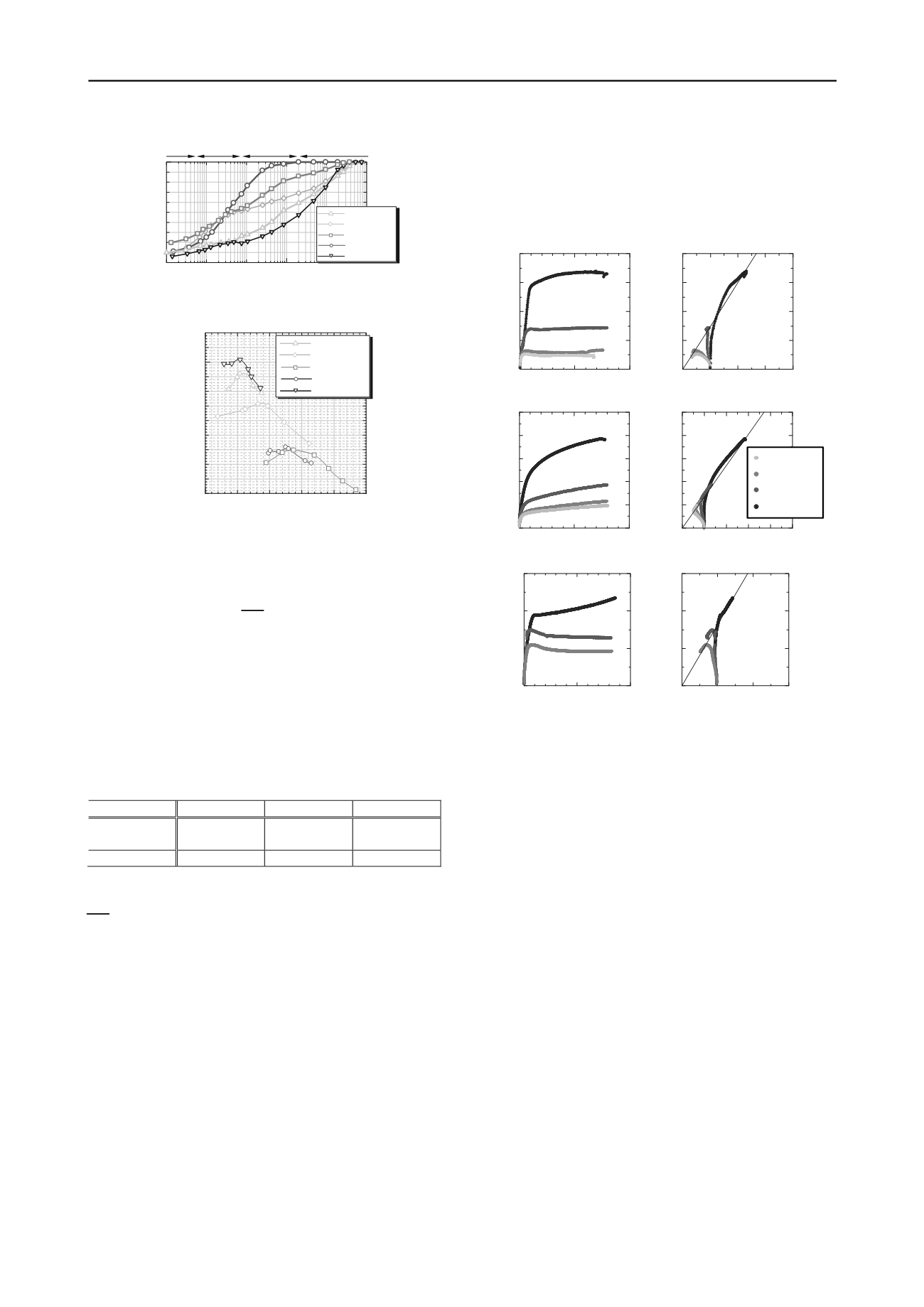

0

50

100

0.001 0.01 0.1

1

10

Grain size (mm)

Percent passing (%)

clay

silt

sand

gravel

100

Material A

Material B

Material C

Material D

Material E

Figure 1. Grain size distribution

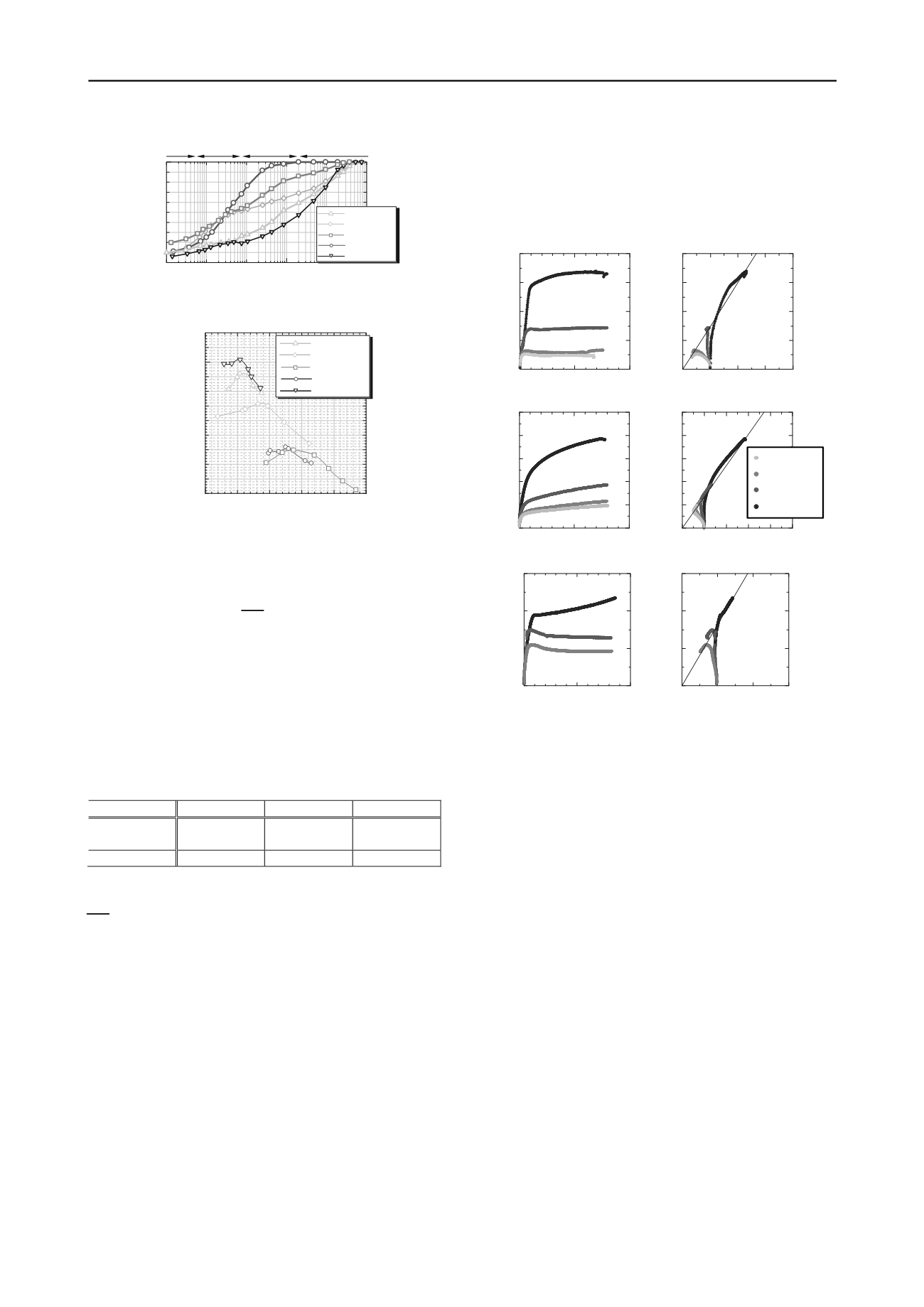

0

20

40

1.10

1.20

1.30

1.40

1.50

1.60

1.70

1.80

1.90

2.00

2.10

Water content

w

(%)

Dry density

d

(g/cm

3

)

Material B

Material A

Material C

Material D

Material E

Figure 2. Compaction test results

3 EFFECT OF COMPACTION ON THE MECHANICAL

PROPERTIES OF EMBANKMENT MATERIALS

For 5 types of materials, CU triaxial compression tests were

carried out under Dc and confining pressure shown in Table 1.

The materials D and E are omitted. When preparing the test

specimens, the Dc was adjusted by changing the compaction

energy. After setting the specimen in the triaxial compression

apparatus, the specimen was saturated with de-aired water using

the double-suction method or the back pressure method. Then

isotropic consolidation process was carried out, and when it was

confirmed that the consolidation completed, the undrained

shearing was carried out under constant axial strain rate.

Table 1 Test conditions

Material A

Material B

Material C

Confining

pressure (kPa)

100, 300

50, 100, 150, 300

100, 300

Dc (%)

85, 90, 95, 100 85, 90, 95, 100

90, 95, 100

Fig. 3 shows that the deviator stress

q

–

shear strain

s

relationship and

q

- mean effective stress

p’

relationship of the

CU triaxial tests when the confining isotropic consolidation

pressure was 100 kPa for materials A through C. The materials

D and E are omitted. In this section, the increase in

q

during

shearing and maximum of

q

as a result of compaction is referred

to as

‘

compaction effect

’

. For material A at the 85 and 90% of

Dc, an increase in

q

associated with a reduction in

p’

was seen

at the initial shear (shear strain

s

= 0–2%). Thereafter, it

exhibited the mechanical behavior of normally consolidated soil

with both

p’

and

q

in a critical state. At the 95% of Dc, there

was almost no reduction in

p’

observed, and thereafter, both

p’

and

q

exhibited a critical state. At the 100% of Dc, an increase

in

q

associated with the increase in

p’

was seen, and the

maximum of

q

increased greatly. It can be seen that if the Dc of

material A is not large, a compaction effect is not seen. With

material B, an increase in

q

associated with the increase in

p’

was seen at all Dc. Also,

q

increased continuously with the

s

,

and the behavior resembles that of pure sand specimen.

However, as for material A, if the Dc of material B is not large,

a compaction effect is not seen. With material C at the 90 and

95% of Dc, softening behavior was seen associated with plastic

compression as a reduction in

q

associated with a reduction in

p’

. This is behavior seen in soft natural deposited clay. On the

other hand, at the 100% of Dc, the shear behavior changed, with

q

increasing in association with an increase in

p’

, and the

compaction effect was exhibited. However, the compaction

effect was small compared with materials A and B.

0

10

20

0

100

200

300

400

Shear strain

s

(%)

Deviator stress

q

(kPa)

0 100 200 300 400

0

100

200

300

400

Mean effective stress

p'

(kPa)

Deviator stress

q

(kPa)

0

10

20

0

100

200

300

400

500

Shear strain

s

(%)

Deviator stress

q

(kPa)

0 100 200 300 400 500

0

100

200

300

400

500

Mean effective stress

p'

(kPa)

Deviator stress

q

(kPa)

Material A

Material B

MaterialC

0

10

20

0

100

200

300

Shear strain

s

(%)

Deviator stress

q

(kPa)

0

100 200 300

0

100

200

300

Mean effective stress

p'

(kPa)

Deviator stress

q

(kPa)

D

c

=85%

D

c

=90%

D

c

=95%

D

c

=100%

Fig. 3 Undrained triaxial test results

4 INTERPRETATION OF COMPACTION EFFECT

BASED ON SOIL SKELETON STRUCTURE CONCEPT

The SYS Cam-clay model is an elasto-plastic constitutive

model that expresses soil skeleton structure as 3 properties,

structure, overconsolidation, and anisotropy, and describes the

evolution of the soil skeleton structure associated with

development of plastic deformation. The major characteristic of

the SYS Cam-clay model is that it can explain the mechanical

behavior of typical clays and sands, as well as intermediate

soils, based on the rate of change of the evolution of the soil

skeleton structure. In this study, the undrained shear behavior

after compaction for 5 materials is simulated by the SYS Cam-

clay model, and each compaction effect of each specimens can

be interpreted based on soil skeleton structure.

Figs. 4 through 6 show the results of reproducing the

mechanical behaviors of materials A through E using the SYS

Cam-clay model. The top 2 graphs are the stress-strain

relationship and the effective stress path, as in Fig. 3. The

bottom left graph shows the decay of structure associated with

shear deformation, and the bottom right graph shows how loss

of overconsolidation associated with shear deformation

occurred; R* indicates the degree of structure, and the closer R*

is to 1, the lower the structure is, while R indicates reciprocal of

OCR.

The material constants and the initial conditions of the

materials are shown in Tables 3 and 4, respectively. The

calculation results were able to reproduce the test results. In the

case of materials for which a large maximum dry density was