1177

Technical Committee 106 /

Comité technique 106

procedure was adopted in order to minimize potential

heterogeneities usually present in undisturbed specimens

allowing a better comparison among conventional methods and

the alternative methodology using centrifuge. Table 2 presents

some typical characteristics and index properties of the soils

samples tested. As shown in Table 2, the void ratio of remolded

specimens is greater than undisturbed specimens. This is

justified in seeking to verify possible deformations in softer

soils induced by high acceleration levels. Therefore, the mass of

soil, at a specific remolding water content, for a known volume

for each soil specimen was calculated. The mass of soil was

placed in layers and a tiny compactor was used just to assent

them until the complete volume was achieved.

Table 2 – Characteristics and index properties

Previously to the centrifuge testing, all soil specimens and all

ceramic disks were soaked with distilled - deaired water. The

soil specimens wetting procedure adopted consisted in gradually

spraying the soil specimens with water until reaching a soaked

state, characterized by a thin water layer formed above the top

boundary of the specimen. The water content reached at the end

of the soaking procedure was assumed to be correspondent to

the saturation condition of each specimen. The ceramic disks

saturation procedure consisted in submerging them during 48

hours into a recipient filled with distilled water and by spinning

them up to 500 rpm in the centrifuge in order to flush air

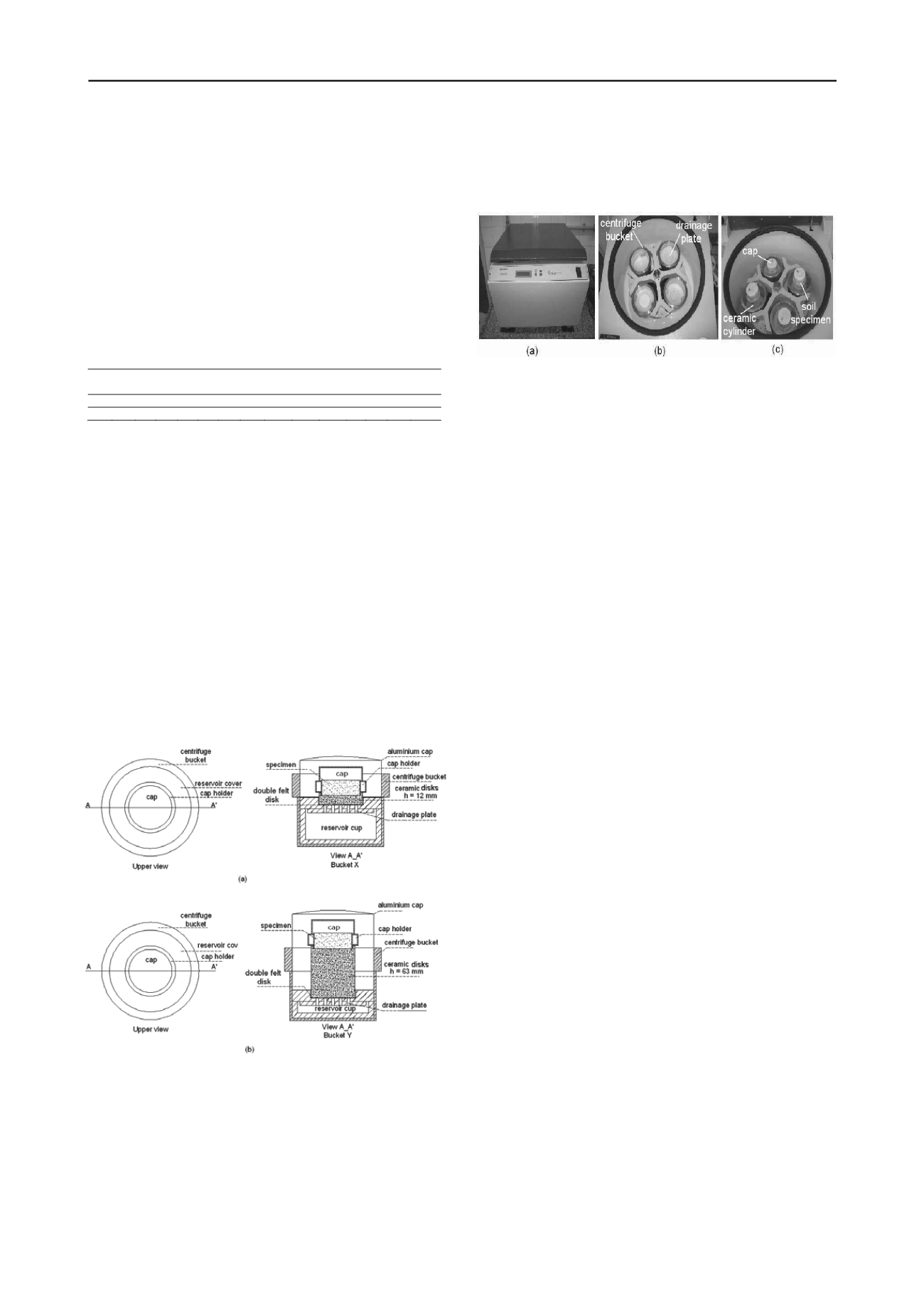

bubbles within them. Thereafter, two setups with 12 mm thick

ceramic disks and two setups with 63mm ceramic disks were

assembled as shown in Figure 2. Subsequently, the four testing

setups were placed into the centrifuge buckets in a symmetric

testing configuration with respect to the centrifuge axis of

rotation in order to avoid in-flight unbalancing.

Figure 2. Setups Details (a) “Bucket X” (12 mm thick ceramic disks);

(b) “Bucket Y” ( 63mm thick ceramic disks).

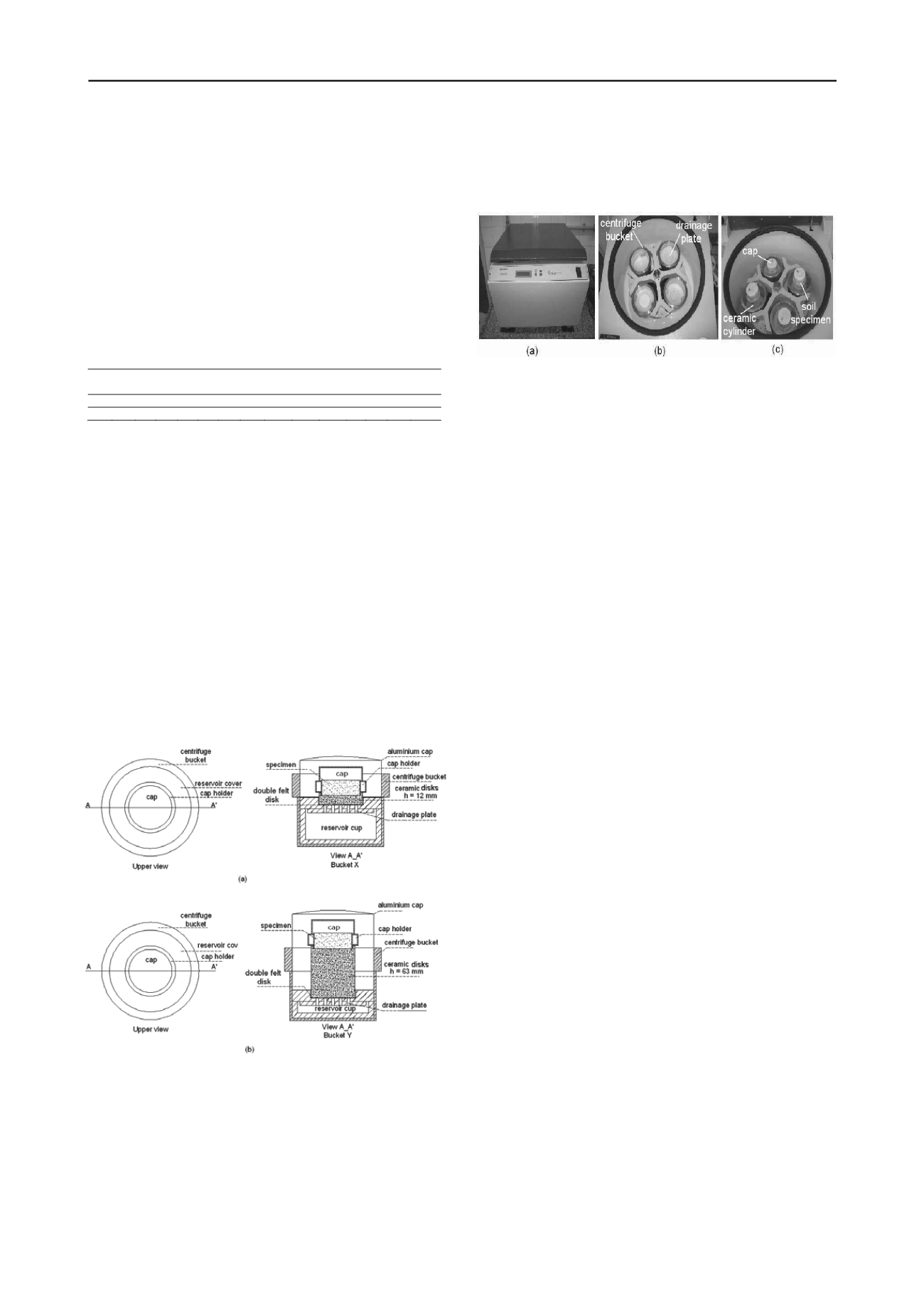

Figure 3 presents the general view of the centrifuge

arrangement before starting the test. The soil specimens´ top

boundary is protected with a PVC cap in order to prevent

evaporation during testing. This cap is fitted over a stiff

aluminum cap fixed in the centrifuge bucket (Figure 2).

Subsequently, the soil specimens are subjected to angular

velocities up to 3000 rpm. The tests were performed with

initially soaked soil specimens displaced over an initially

soaked high flow ceramic disk and submitted to successive

increased gravities inducing successive unsaturated states

without any external interference (even stopping the centrifuge).

Figure 3. Views of Cientec CT 6000 small-scale centrifuge: (a) external

view; (b), (c) internal view.

The methodology allows determining simultaneously two

pairs of soil moisture – suction relationships at each induced

gravity applied. Applying angular velocities of 300, 500, 1000,

1500, 2000, 2500 and 3000 rpm allows determining

experimentally 14 soil moisture – suction relationships. The

proposed setup configuration allows evaluating the data

repeatability once the specimens with same ceramic disk

thickness are subject to similar suction magnitudes and,

therefore, they should have similar moisture changes in a

specific testing step (denoted by similar changes in specimens´

weight). Due to the absence of in-flight instrumentation, the no-

flow steady-state moisture profile condition was checked by

stopping the centrifuge equipment and checking any change in

each specimen´s weight. The equilibrium condition is yielded

when a constant specimens´ weight is achieved. After reaching

the no-flow steady-state moisture profile condition at the 3000

rpm run, all soil specimens were oven dried for final water

content determination. The water content magnitudes of each

intermediary testing step were then back calculated and the

respective SWRC plotted.

In order to evaluate any potential effect of consolidation

during centrifugal flow, it was evaluated the soil specimen´s

height at each centrifuge monitoring stops. It was not observed

any volume change for angular velocities lower than 1500 rpm.

For angular velocities higher than 1500 rpm, it was observed

changes in the specimen´s height of 0.8 mm, 0.4 mm for RY,

UY, respectively. These height changes correspond to 4 %, 2 %

of volume changes respectively. Once the volume changes

observed were small, the corresponding volumetric water

contents were evaluated considering the initial soil unit weight

even for angular velocities higher than 1500 rpm.

The

corresponding suction magnitudes of the tests that underwent

volume changes were evaluated considering the actual radius

magnitude calculated at each testing step.

4 RESULTS AND DISCUSSION

Figures 4 and 5 present the comparison among the SWRC

obtained by conventional methods and depicted using the van

Genuchten (1980) mathematical model, and the experimental

data obtained following the methodology proposed herein.

Figure 4 shows the RY testing results while Figure 5 shows the

UY testing results.

Analyzing the results in Figures 4 and 5 it can be observed

that the experimental data obtained through the proposed

methodology agrees with the experimental data obtained by

conventional methods such as filter paper method, plate

extractor and suction funnel. Concerning the SWRC

mathematical description, it can be noted in Figures 4 and 5 that

the van Genuchten (1980) model describes accurately the soil´s

suction – moisture relationship observed experimentally.

Sand Silt Clay LL LP

IP

W

γ

γs

γd

e

n

Sr ASTM

(%) (%) (%) (%) (%) (%) (%) kN/m³ kN/m³ kN/m³

(%) (%) (2003)

RY 55.0 36.0 7.0 50.2 24.6 25.6 19.3 16.6

26.7

13.9 0.9 47.8 56.3

SC

UY 55.0 36.0 7.0 50.2 24.6 25.6 12.0 17.1

26.7

15.3 0.8 42.7 42.8

SC