706

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

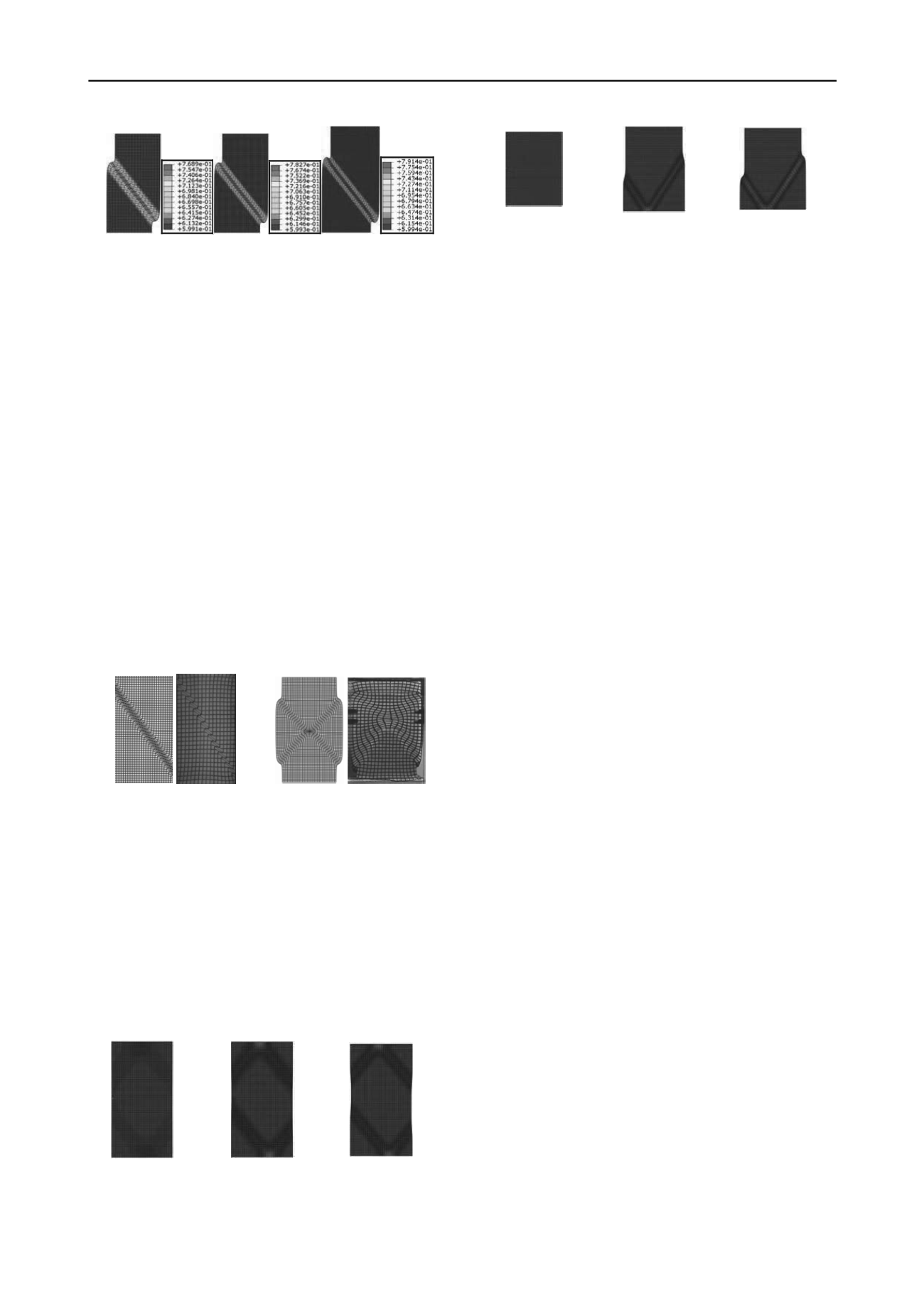

(a) coarse mesh

(b) medium mesh

(c) fine mesh

Figure 5. Deformed finite element mesh along with contour plot of void

ratio for (a) coarse mesh, (b) medium mesh, and (c) fine mesh

It has been reported from experimental observations of

biaxial compression tests (Alshibli and Sture 2000) that the

behavior of granular materials is dependent on the boundary

conditions of specimen. The following simulations illustrate the

boundary condition effect on the shear band formation. The

finite element calculations are performed for two separate cases:

(1) smooth and (2) very rough surfaces at the top and bottom of

specimen. The obtained finite element results are compared

with those of experiments (Alshibli and Sture 2000). Figure 6

displays that multiple shear bands develop in the specimen

when the bottom boundary is very rough (Figures 6(c) and

6(d)). The finite element results demonstrate that shear band

location and mode are highly influenced by the prescribed

boundary conditions, prescribed along the top and bottom

surfaces of specimen (Figures 6(a) and 6(c)), which are

consistent with experimental observations (Figures 6(b) and

6(d)) (Alshibli and Sture 2000). According to finite element

results, two principal mechanisms of shear banding may occur

in granular materials under plane strain compression: in the first

mechanism, a single shear band is formed inside the specimen

(Figures 6(a) and 6(b)), while in the second, more than one

shear band can occur if the movement of bottom boundary is

restrained under plane strain condition (Figures 6(c) and 6(d)).

(a)

(b)

(c)

(d)

Figure 6. Comparison between shear banding patterns obtained from

numerical simulations and experiments (Alshibli and Sture 2000): (a)

and (b) free rotational boundary, (c) and (d) restrained rotational

boundary

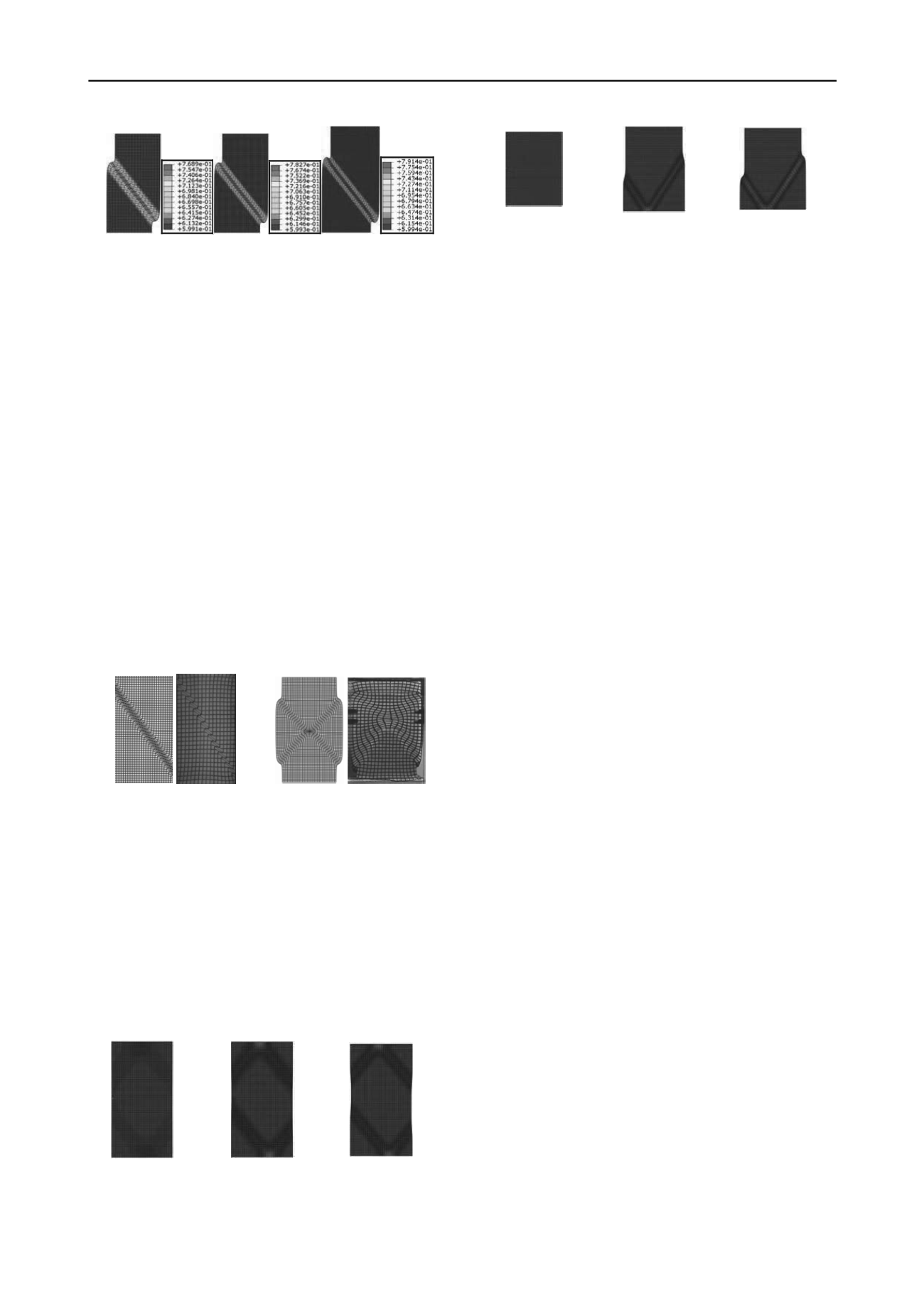

The behavior of granular material is also affected by the

geometry of specimen. If the length to width ratio of specimen

would be larger than 2.0, then the failure will not, to some

extent, be affected by the boundary conditions and a single

shear band is formed (Figure 5). For the ratio equal to 2.0, a

complicated pattern of shear banding is developed within the

specimen, as shown in Figures 7(a)-7(c). For smaller values of

length to width ratio, a reflection of shear band is observed

when it hits the bottom rigid boundary (Figures 7(d)-7(f)).

Axial strain = 13%

Axial strain = 5%

Axial strain = 2%

(c)

(b)

(a)

Axial strain = 13%

Axial strain = 5%

Axial strain = 0%

(f)

(e)

(d)

Figure 7. Shear band formation process in biaxial specimen with

different geometries: (a), (b), (c) length to width ratio = 2, and (d), (e),

(f) length to width ratio = 1.33

5 CONCLUSION

An extended elasto-plastic Lade’s model along with

embedded Cosserat rotations and couple stresses, can simulate

properly the localization phenomenon in the granular materials

under different loading conditions. Polar quantities are

noticeable in the shear band. Cosserat rotations, increasing void

ratios, high gradient of micro-curvatures and couple stresses can

be used to identify the shear band. The couple stress values is

found to be very small in magnitude compared with the stresses;

however, they have significant effects on the material behavior,

partucularly in the softening regime. Location and evolution of

shear bands are mainly affected by the micro-polar kinematical

boundary conditions and rotation resistance of soil grains

prescribed along the boundries. The length scale and size of

specimens have substantial influence on observed pattern of

shear banding in granular materials.

6 REFERENCES

Hall S.A., Bornert M., Desrues J., Pannier Y., Lenoir N., Viggiani G.

and Bésuelle P. 2010. Discrete and continuum analysis of localised

deformation in sand using X-ray μCT and volumetric digital image

correlation.

Géotechnique

60(5), 315-322.

de Borst R. 1991. Simulation of strain localization: a reappraisal of the

Cosserat continuum.

Engineering Computations

8, 317–332.

Mühlhaus H.B. 1986. Shear band analysis in granular materials by

Cosserat theory.

Ingenieur Archiv

56, 389-399.

Vardoulakis I. and Sulem J. 1995.

Bifurcation Analysis in

Geomechanics

. Blackie Academic & Professional, Glasgow, UK.

Lade P.V. and Kim M.K. 1988. Single hardening plasticity model for

frictional materials.

Computers and Geotechnics

6, 13-29.

Kim M.K. and Lade P.V. 1988. Single hardening constitutive model for

frictional materials.

Computers and Geotechnics

5, 307-324.

Ebrahimian B., Noorzad A. and Alsaleh M.I. 2012. Modeling shear

localization along granular soil–structure interfaces using elasto-

plastic Cosserat continuum.

International Journal of Solids and

Structures

49, 257–278.

Oda M. and Iwashita K. 2000. Study on couple stresses and shear band

development in granular media based on numerical simulation

analyses.

International Journal of Engineering Science

38, 1713-

1740.

Vardoulakis I. 1980. Shear band inclination and shear modulus in

biaxial tests.

International Journal of Numerical and Analytical

Methods in Geomechanics

4, 103-119.

Desrues J., Chambon R., Mokni M. and Mazerolle F. 1996. Void ratio

evolution inside shear bands in triaxial sand specimens studied by

computed tomography.

Géotechnique

46, 529-546.

Alshibli K.A. and Sture S. 2000. Shear band formation in plane strain

experiments of sand.

ASCE Journal of geotechnical and

geoenvironmental engineering

126(6), 495-503.