714

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

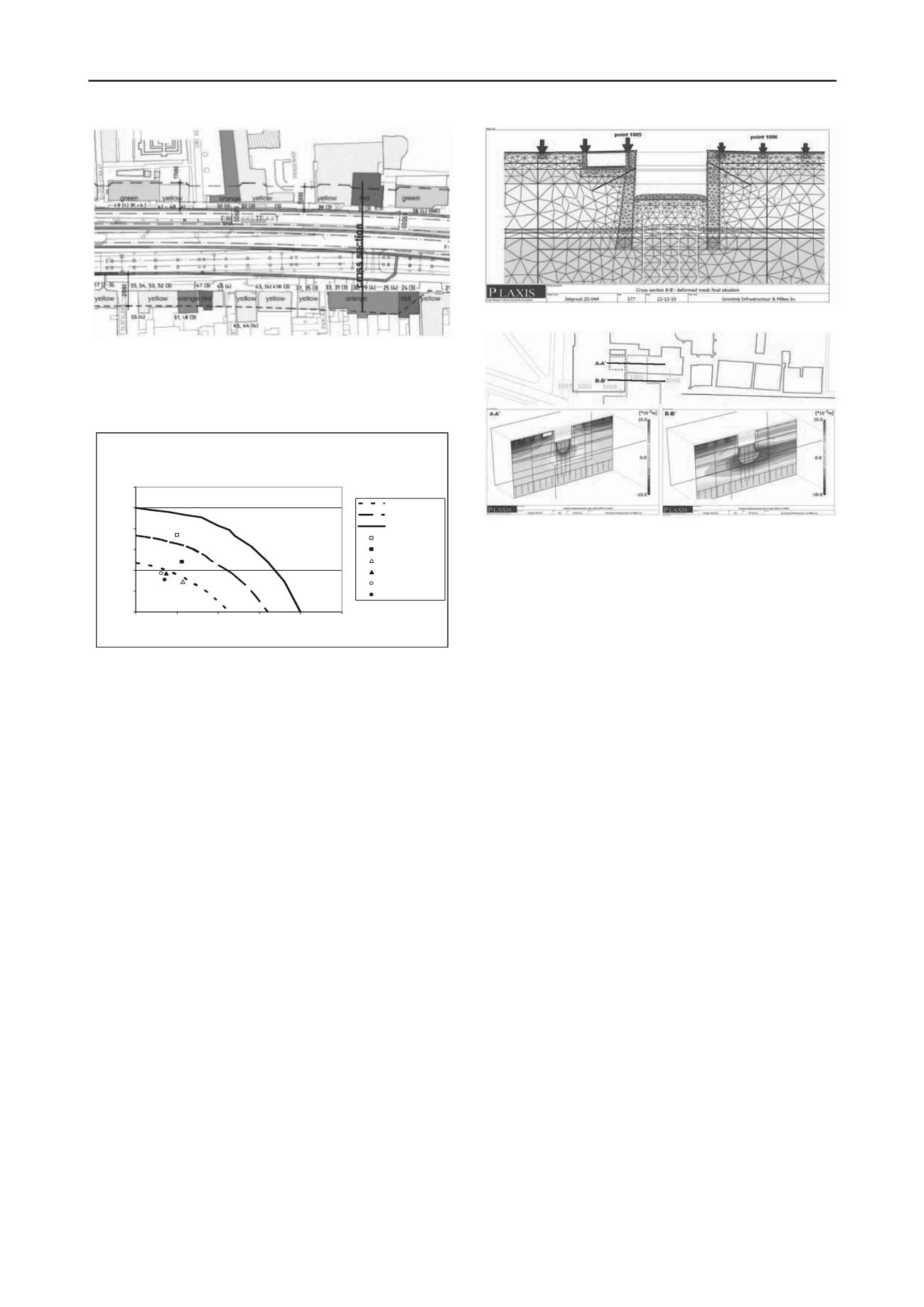

Figure 6. Cross section FEM Method 2.

Figure 4. Cross section location map.

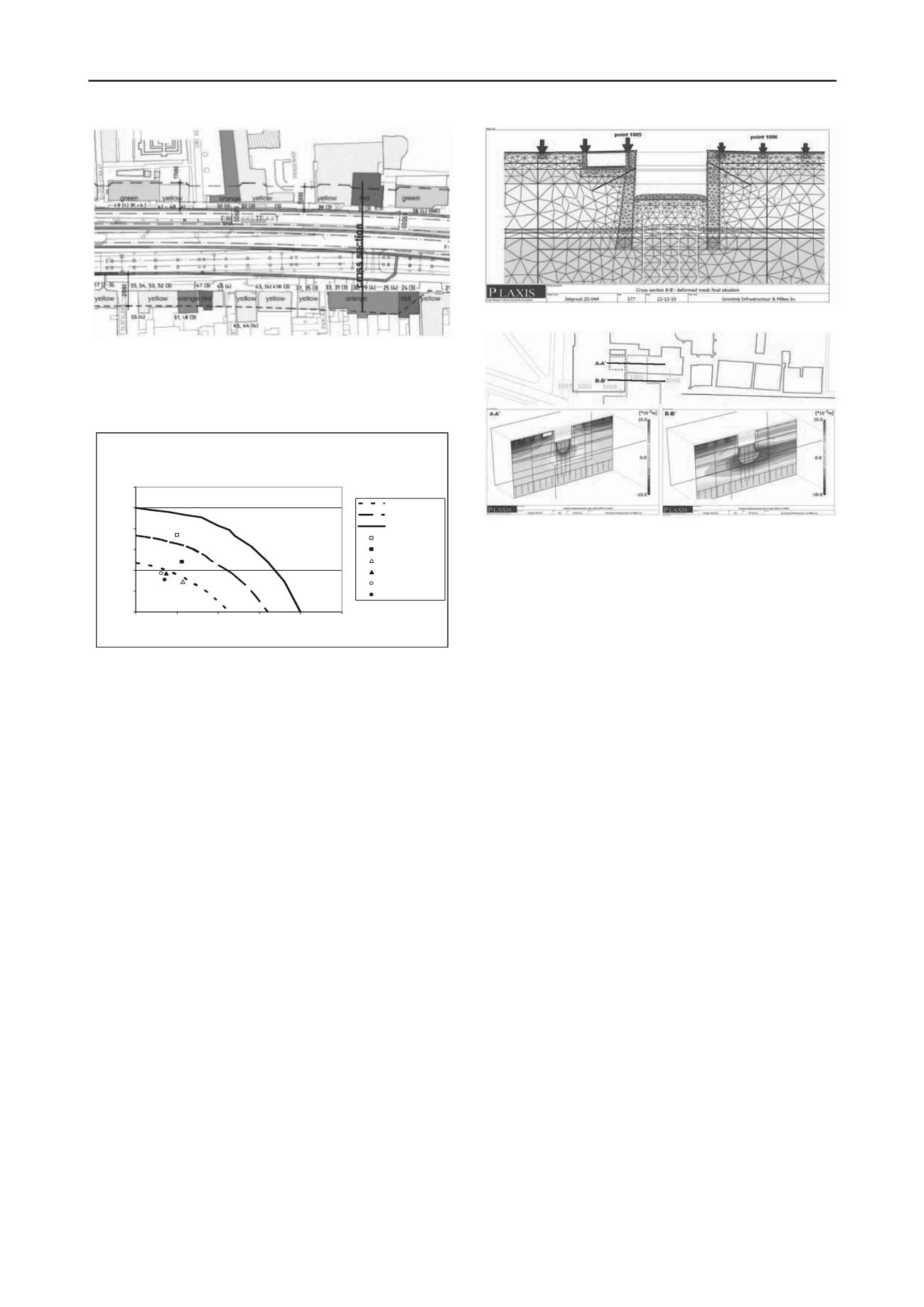

Figure 5 presents an up-scaled graph based on Boscardin and

Cording (1989). It shows that the most critical construction

stage for Phoenixstraat 30 is at the end of the construction of the

eastern tunnel tube (about 50% the total construction period).

RESULTS DEFORMATION PREDICTION

CROSS SECTIONPHOENIXSTRAAT 30 - SPOORSINGEL 25

0

0,2

0,4

0,6

0,8

1

1,2

0

0,5

1

1,5

2

2,5

Angular distortion x10

-3

Horizontalstrainx10

-3

Class IV (red)

Class III (orange)

Class II (yellow)

Ph30-II-50%

Ph30-II-End

SP25-III-50%

SP25-III-End

Ph30-IV-50%

Ph30-IV-End

Class IV

Class II

Class III

Figure 5: Verification of allowable building deformations

Figure 7. 3D-FEM postdiction of vertical displacements.

Note: Figure 7 should be read in combination with Figure 6.

The main reason for selection of Method 2 was to assess

foundation deformations as well as swell deformations of the

bottom of the excavation based on realistic stress distribution.

5 CONCLUSIONS

Comments Figure 5:

Phoenixstraat 30, new part (class II): II-50% (construction stage),

II-End (final stage)

Phoenixstraat 30, old part (class IV) IV-50% (construction stage),

IV-End (final stage)

In this paper two methods are described for finite element

modelling of diaphragm wall supported excavations.

Advantages and disadvantages are given that may contribute to

pre-selection of the model that fits best to the specific project

features.

Spoorsingel 25 (class III) III-50% (construction stage), III-End

(final stage)

The critical construction stage for Spoorsingel 25 is the final

stage. Further, the verification of deformation criteria proves

that the combination of horizontal strain and angular distortion

is met during all intermediate design construction stages.

Method 1 was applied for modelling the railway tunnel in

Delft because of the requirement of flexible design models in

combination with shallow foundations sensitive to

deformations.

For the case in Assen Method 2 was selected. The

requirements for this case better agree with the advantages of

better visualisation of wall and soil behaviour and calculation of

stresses and deformations in soil, wall and foundation.

4.3

Drents Museum Assen – Method 2

One of the critical requirements was the maximum tolerated

settlement and heave of the foundation during the excavation

below the monumental building. The maximum allowable

vertical displacement for the foundations is 5 mm to 10 mm

which corresponds to relative rotations of 1:500 to 1:1,000. The

existing foundations are modeled as separate shallow

foundations (including basement) as shown in Figure 6.

6 ACKNOWLEDGEMENTS

The authors would like to thank their colleague Remy Delpeuch

for the translation of the abstract into decent French.

7 REFERENCES

To evaluate the applied geotechnical calculation models and

the predicted soil and structural behaviour, post diction analyses

with 3D-FEM have been performed (Figure 7) based on the

latest monitoring results during execution. Due to the wet

excavation, the foundation settlement was 4 mm to 9 mm. After

dewatering the excavation, the postdicted foundation rebound

was about 4 mm to 5 mm due to developing tension resistance

in the anchors below the elastic underwater concrete floor

during the instantaneous swell of the underlying soil layers and

the primary swell of the deeper slightly over-consolidated clay.

Boscardin, M.D. and Cording, E.J., 1989. Building Response to

Excavation-induced Settlement.

Journal of Geotechnical

Engineering

(ASCE). 115(1), 1-21

CUR 231, 2010. Handboek diepwanden, Ontwerp en uitvoering.

Stichting CURNET, Gouda

, 2010

EN 9997-1, 2011. Geotechnical design of structures -Part 1: General

rules.

Nederlands Normalisatie Instituut,

December 2011

Van der Stoel, A.E.C., 2001. Grouting for pile foundation

improvements.

Delft University of Technology

, 2001