625

Technical Committee 102 /

Comité technique 102

4 DRILLING AND IN-SITU TESTING

Drilling for the Supplementary Soil investigations was carried

out from five drilling barges equipped with suspended rotary

top drive drilling rigs and passive heave compensation.

Three different passive heave compensation systems were

installed on the five drilling barges used for the investigations:

A strictly mechanical weight load system on one barge,

A spring loaded mechanical system on three barges, and

A hydraulic piston system on one barge.

The above mentioned systems were able to be operated with

good results (in terms of heave compensation) at maximum

heave of approx. 0.7 to 1.0 m.

Undisturbed samples (fine grained soils) were primarily re-

trieved with a 76 mm diameter thin walled stationary piston

sampler with stainless steel seamless sampling tubes of length

1.0 m.

Undisturbed samples were sealed with wax and taped-shut

end caps immediately after retrieval. Storage and transportation

were carried out vertically in wooden boxes filled with shock

absorbing material (coarse sawdust).

SPT testing in coarse grained soils was generally carried out

at 1.5 m intervals, and the hydraulic head in the boreholes was

as a minimum kept at a level corresponding to sea level. The

SPT-N Energy Transfer Ratio (ETR) was determined by carry-

ing out PDA tests of the equipment used from three different

barges.

In situ shear vane testing was performed at 1 m intervals in

fine grained soils using the Chinese electrical vane equipment

with cruciform vanes of dimensions 75 mm x 150 mm for the

softer clays.

CPTU testing was carried out using underwater seabed pie-

zocone penetration systems deployed from barges where the po-

sition was maintained by means of 4 heavy anchors. Two dif-

ferent CPTU systems were used, the Wheeldrive Seacalf with

200 kN thrust and the ROSON system with a 100 kN thrust. All

CPTU testing was carried out in accordance with the ISSMGE

(2001) standard.

5 LABORATORY TESTING

Classification testing for the Supplementary Soil investigations

consisted of natural moisture content, bulk and dry density, par-

ticle density, Atterberg limits, particle size distributions, maxi-

mum and minimum dry densities and organic content.

Incremental loading (IL) oedometer testing was carried out on

both undisturbed fine grained soil samples and reconstituted

coarse grained soil samples in accordance with BSI (1990a).

The specific schedule for the IL oedometer tests on fine

grained samples was designed to take into account the in-situ

and pre-consolidation stress together with the anticipated stress

history imposed by the construction activities.

The maximum net stress increments under the tunnel ele-

ments were not expected to lead to exceedance of the in-situ

stresses neither along the middle part of the immersed tunnel

alignment nor towards the artificial islands.

In view of the above, special attention was paid to determine

reliable estimates of the values of the pre-consolidation stress

and the reloading stiffness. The IL oedometer tests carried out

on fine grained samples were performed in two batches:

Batch I IL oedometer tests: Mainly carried out to provide an

estimate of the pre-consolidation pressure (and the virgin

compression index),

Batch II IL oedometer tests: Carried out to provide an esti-

mate of the reloading stiffness from varying unloading

stress levels below the pre-consolidation stress estimated

from the Batch I tests.

Initial unloading/reloading steps from/to the presumed in-situ

stress were included for both the Batch I and II IL oedometer

tests in an attempt to quantify and reduce the sample distur-

bance resulting from sample retrieval, transportation and extru-

sion. The application of the this initial branch of unload-

ing/reloading conceivably improved the apparent sample quality

significantly, as e.g. evaluated in accordance with NORSOK

(2004), on average from poor to very good/excellent sample

quality.

Triaxial testing of fine grained undisturbed samples was car-

ried out as Consolidated Anisotropic Undrained (CAU) triaxial

tests in accordance with BS1(1990b).

The triaxial tests allowed for site specific calibration of the

N

kt

cone factor for determination of realistic undrained shear

strengths based on CPTUs. Secondly, they allowed the value of

s

u

/σ'

pc

for the normally consolidated condition (often referred to

as the c/p ratio) to be determined. In this way a site specific

SHANSEP relation could be established allowing determination

of the undrained shear strength variation from actual unload-

ing/reloading cycles as a consequence of construction activities.

6 CPTU CORRELATIONS

For the purpose of establishing a detailed geological and geo-

technical model of the subsurface conditions, a combination of

cored boreholes and closely spaced CPTU soundings was se-

lected as the primary method of investigating the project site.

The CPTUs and boreholes were generally carried out as de-

scribed. The locations of the boreholes were arranged to provide

a total of 68 Nos. pairs of boreholes and CPTUs along the

alignment. This allowed for a site specific correlation between

the stratigraphy as encountered within the boreholes and the

corresponding principal CPTU properties with respect to cone

resistance, friction ratio and pore pressure. The boreholes and

CPTUs carried out in pairs were generally positioned within a 5

m distance from each other.

Initially, two approaches were investigated to find the most

appropriate correlation model for the site investigation data,

namely a conventional method developed by Robertson et al

(Lunne et al 1997) and a site specific approach based on pairing

the CPTU and borehole data.

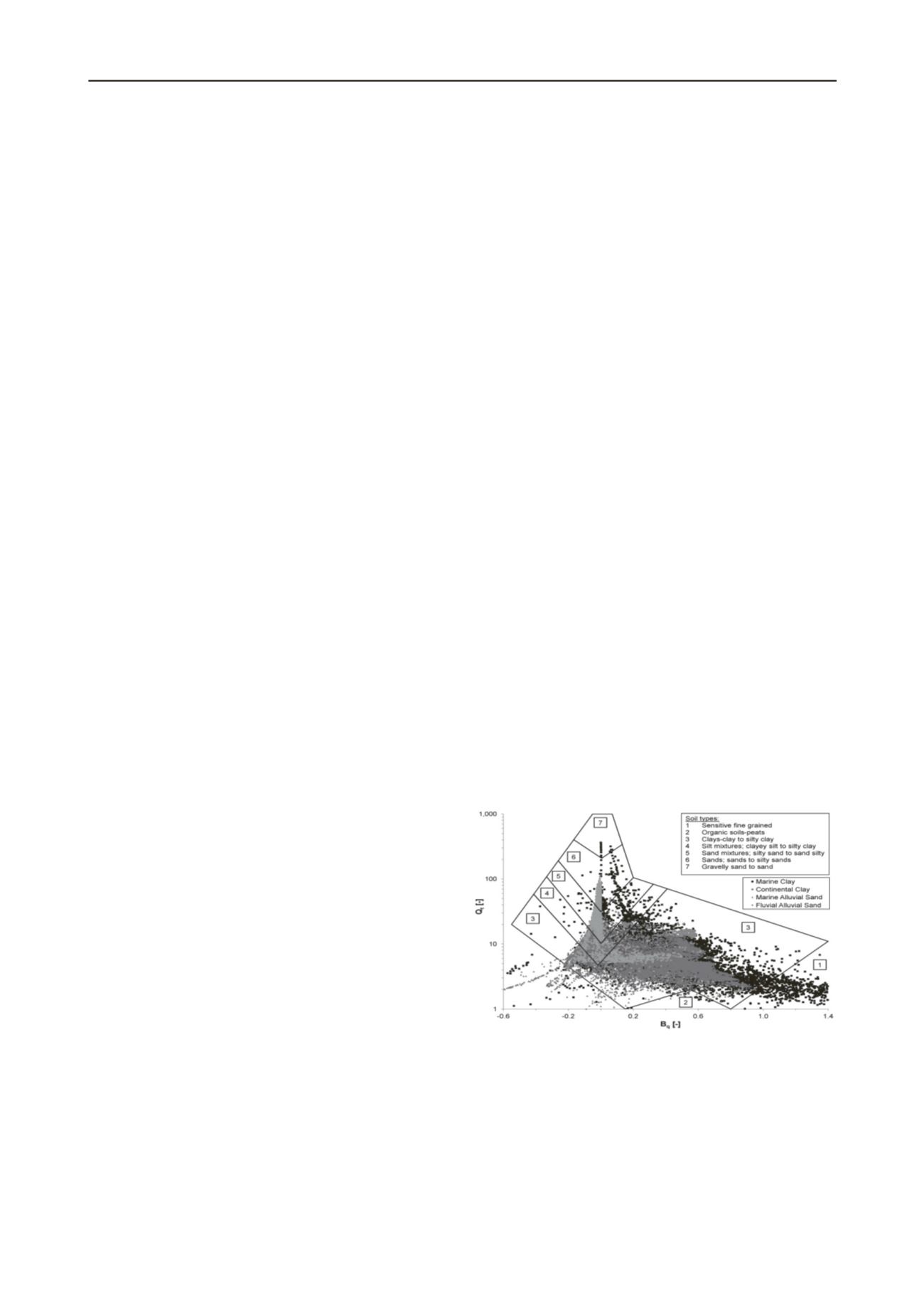

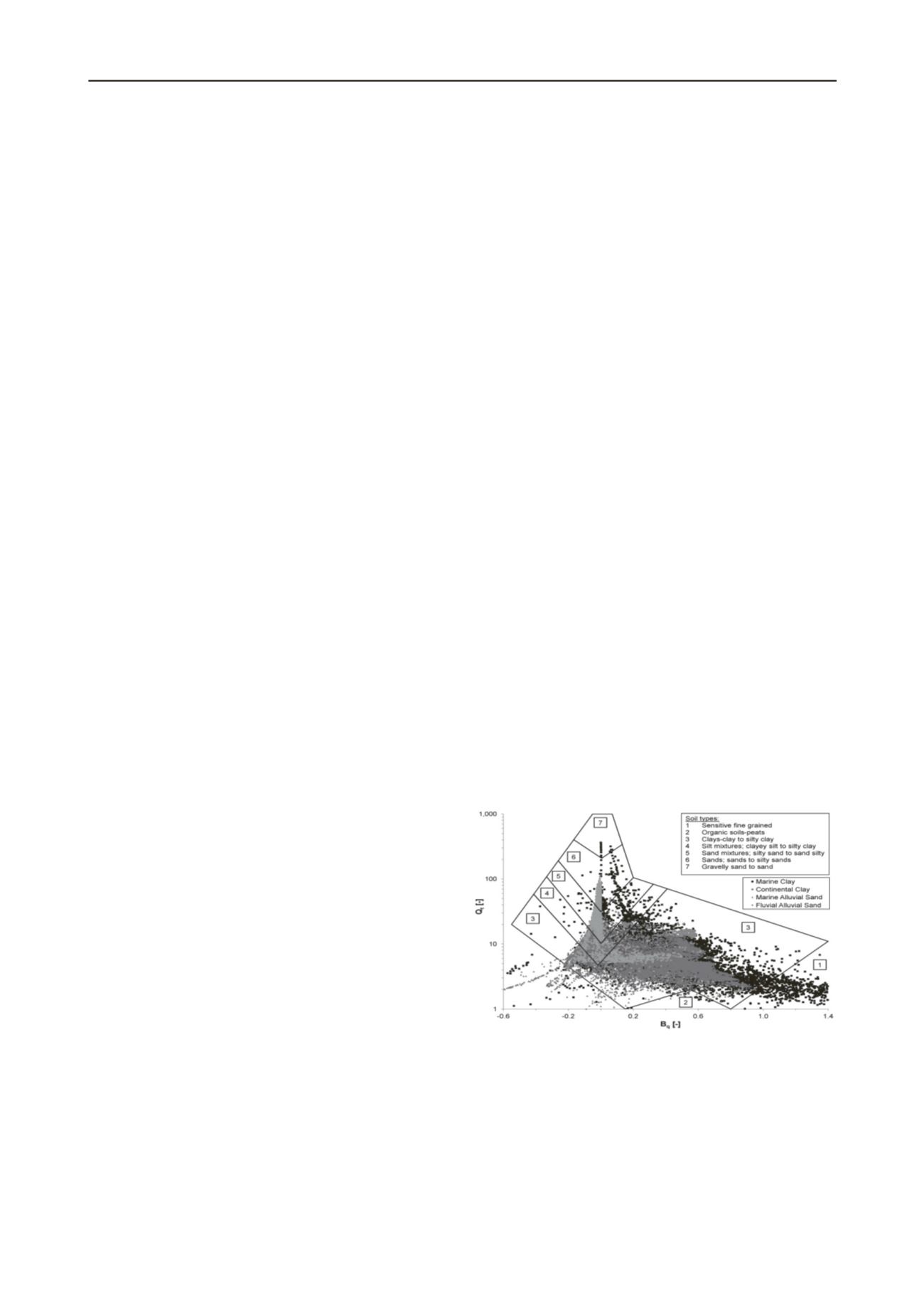

The depiction of the site CPTU results categorised into the

different main geological units and using the Robertson classi-

fication chart is shown in Figure 4.

Figure 4. CPTU results superposed on soils classification chart (Lunne

et al 1997)

.

Instead, the CPTU data were analysed statistically, yielding rep-

resentative ranges and frequency distributions of each geo-

logical unit with respect to cone resistance, friction ratio and

excess pore pressure. In this way a unique "foot print" was pro-

duced for each geological unit as e.g. shown in Figure 5.