620

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The site is vulnerable to relatively high levels of seismic

loading, with a design peak ground acceleration of

approximately 0.53g per the building code. Deaggregation

analysis indicated the corresponding moment magnitude to be

6.7. The area is zoned for industrial or commercial

development. The owners are evaluating remedial measures to

make the site suitable for building development.

There are no industry-accepted standards or case histories to

predict settlements of inert debris fill containing significant

oversize fragments and significant open cavities. Case histories

of seismic settlements of unsaturated fills are generally limited

to earthfill/rockfill dams and compacted soil fills. Laboratory

cyclic simple shear test data relating cyclic shear strain to

volumetric strain, that may be used to estimate the settlement of

unsaturated fills under seismic shaking, are limited to sands

(Silver and Seed 1971, Pyke et al 1975), and finer grained

compacted fills (Stewart et al 2002). Charles (2008) documents

case histories of long-term settlement and collapse potential of

uncontrolled opencast mining backfills in Britain. The City of

Irwindale is currently conducting a laboratory study to evaluate

the potential for wetting induced settlements (hydrocollapse) in

inert debris fills.

2 FIELD INVESTIGATIONS

Field investigations for this site included Becker hammer

borings, surface and downhole geophysical surveys, downhole

video logging, test excavations and large scale in-situ density

and grain size distribution tests. Neither the Becker penetration

tests (BPTs) nor the surface and downhole seismic surveys,

proved to be suitable to characterize the heavily nested and

voided nature of the fills. The presence of very large size

fragments appear to significantly skew the measured Becker

blow counts and shear wave velocities, making these methods

incapable of adequately differentiating between well

compacted, grading code - compliant fills (derived from the

same debris materials), and the loose debris fills with

voids/cavities. This conclusion has been confirmed by studies

performed by the City of Irwindale at other debris fill sites

(Geomatrix, 2007).

Mapping of two deep test excavations to 21 m depth in the

poorly controlled debris fill, confirmed the layered filling

pattern consisting of thick rubble fill lifts capped by thin soil

layers. The layered filling pattern was also apparent in the BPT

logs. The rubble fill consisted of concrete clasts and blocks up

to 2 m in size (with abundant rebar), mixed with brick, tiles,

asphalt concrete, crushed glass and variable amounts of soil

infill. Large voids, cavities and nesting were very common.

Eight large diameter ring density tests (1.8 m diameter x 1.5

m deep) performed as per ASTM D5030 in the inert debris fill

at various depths (ranging from 5 to 15 m below ground

surface) in the test excavations, and eight sand cone tests

performed on soil layers or soil rich fills gave the following

results.

Table 1. Results of In-situ Density Tests

In-situ Dry Density (gm/cc)

Material

Range

Average

Average Void

Ratio

Inert Debris Fill

1.22 – 2.03

1.77

0.43 (e

t

)

Soil Layers

1.45 – 1.86

1.64

0.62 (e

s

)

The in-situ densities of the inert debris fill were compared

to field maximum achievable density (MAD) tests performed on

inert debris materials placed in 30-cm thick lifts and compacted

by 50 passes of heavy earthmoving equipment (combination of

Caterpillar 820 front end loader and 825 compactor). The

corresponding MAD dry densities ranged from 2.03 to 2.13

gm/cc.

A qualitative evaluation of the voided / nested structure of

the inert debris fill was performed by measuring the rate of

water percolation in large diameter test holes. After completing

the large diameter in-situ density tests, the plastic sheeting used

to line the test hole was pulled out and the water level drop was

monitored. The water levels dropped very rapidly (emptied in a

matter of minutes) in test holes in debris fills, while the water

levels stayed full for several days in the MAD tests holes,

confirming the presence of significant voids / cavities in the

debris fill.

Field bulk gradation tests performed on the bulk samples

excavated from the density test pits showed the following

distribution:

Table 2. Summary of Field Gradation Test Results

Material Size

Range (%)

Average (%)

Boulders (>300 mm)

3 to 23

11

Cobbles (>75 mm)

10 to 25

18

Gravels (>19 mm)

6 to 20

14

Finer than (19 mm)

44 to 66

57

Visual observations of the materials removed from the test

excavations suggest that the oversize fraction is greater than the

amounts listed above, since representative amounts of very

large concrete clasts could not be included in the material from

1.5 m diameter test holes. The actual boulder size fraction (>

300 mm) was estimated to be in excess of 20 percent by weight.

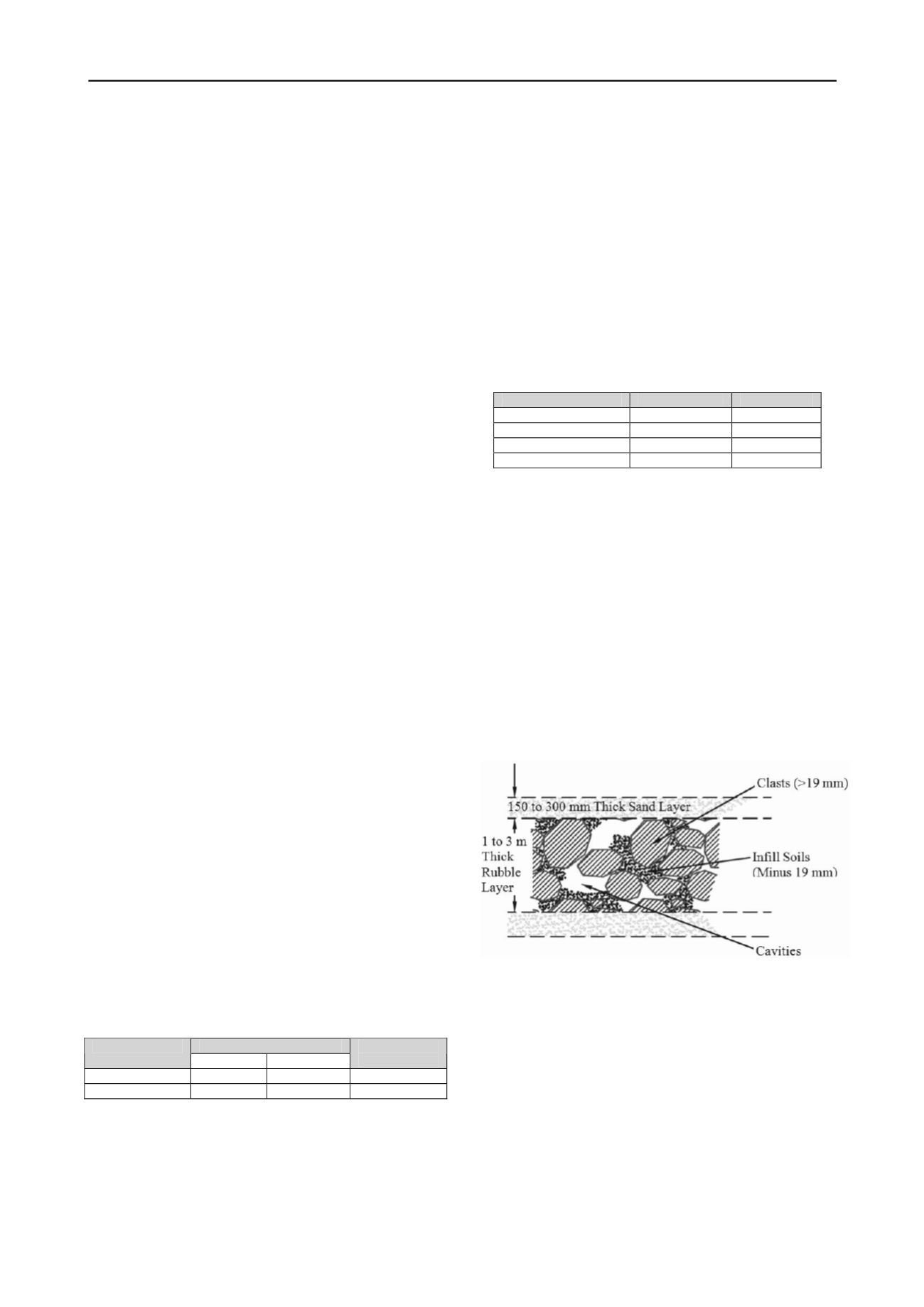

3 SETTLEMENT MODEL

The settlement model used in the analysis considered the

layered nature of the debris fill consisting of a succession of 1 to

3 m thick voided and nested rubble lifts capped by 15 to 30 cm

thick loose to medium dense soil lifts. The total debris fill may

be considered to consist of nested oversize clasts (defined as

materials lager than 19 mm for purposes of this analysis), infill

soils (minus 19 mm fraction that partially fills the cavities

between clasts and also caps individual layers of rubble), and

cavities (Figure 2).

Figure 2. Debris Fill Structure

When subjected to seismic loading and/or saturation due to

groundwater rise, the predominant mechanisms of settlement in

the debris fill are considered to be partial filling of the cavities

by fines migration (cap soils migrating into the underlying

nested rubble), and collapse of the nested structure. Volumetric

compression of the infill soils and soil lifts will also take place,

but they are considered to be significantly smaller than the two

dominant settlement mechanisms. The volume of cavities

between the nested clasts, as a percentage of the total volume of

fill, will, therefore, form an upper bound of the potential

volumetric strain / settlement of the fill. The volume of cavities

in the fill (Figure 2) as a ratio of the total fill volume, was

estimated as shown below, based on the void ratio of the entire

debris fill, e

t

(calculated from large diameter ring density tests),

void ratio of the infill soils, e

s

(calculated from the sand cone

density tests), the ratio of weight of clasts to weight of infill