616

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 GEOLOGICAL CONDITIONS

Geological conditions of the construction site can be

described as unfavorable for civil engineering and especially for

high-rise buildings. Weak water-saturated soils lies to the depth

of 30 ... 35 m. Underneath these soils is a layer of moraine

deposits of small thickness. From a depth of 45 m liesVendian

clay. Rock, commonly used as a bearing stratum for high-rise

buildings are located at depths of over 200 m. Considering the

aforementioned facts Vendian clay was selected as the bearing

layer for the Okhta tower pile foundation. Vendian clay is

relatively strong soil and classified as hard clay and weak rock

at the same time. Despite the relatively high strength properties

Vendian clay exhibits long-term development of deformations

in time under load. It should be noted that engineering

properties of these soils in Saint-Petersburg is mostly unstudied.

3 TESTING SETUP

The test program was design in such a way as to achieve the

following goals:Determination of the bearing capacity of

barrette and it’s individual fragments;Determination of load-

settlement

characteristics

for

"top-down"

loading

scheme;evaluation of the Young modulus for the underlying the

barrette base;Evaluation of interface strength on the shaft of the

barrette.

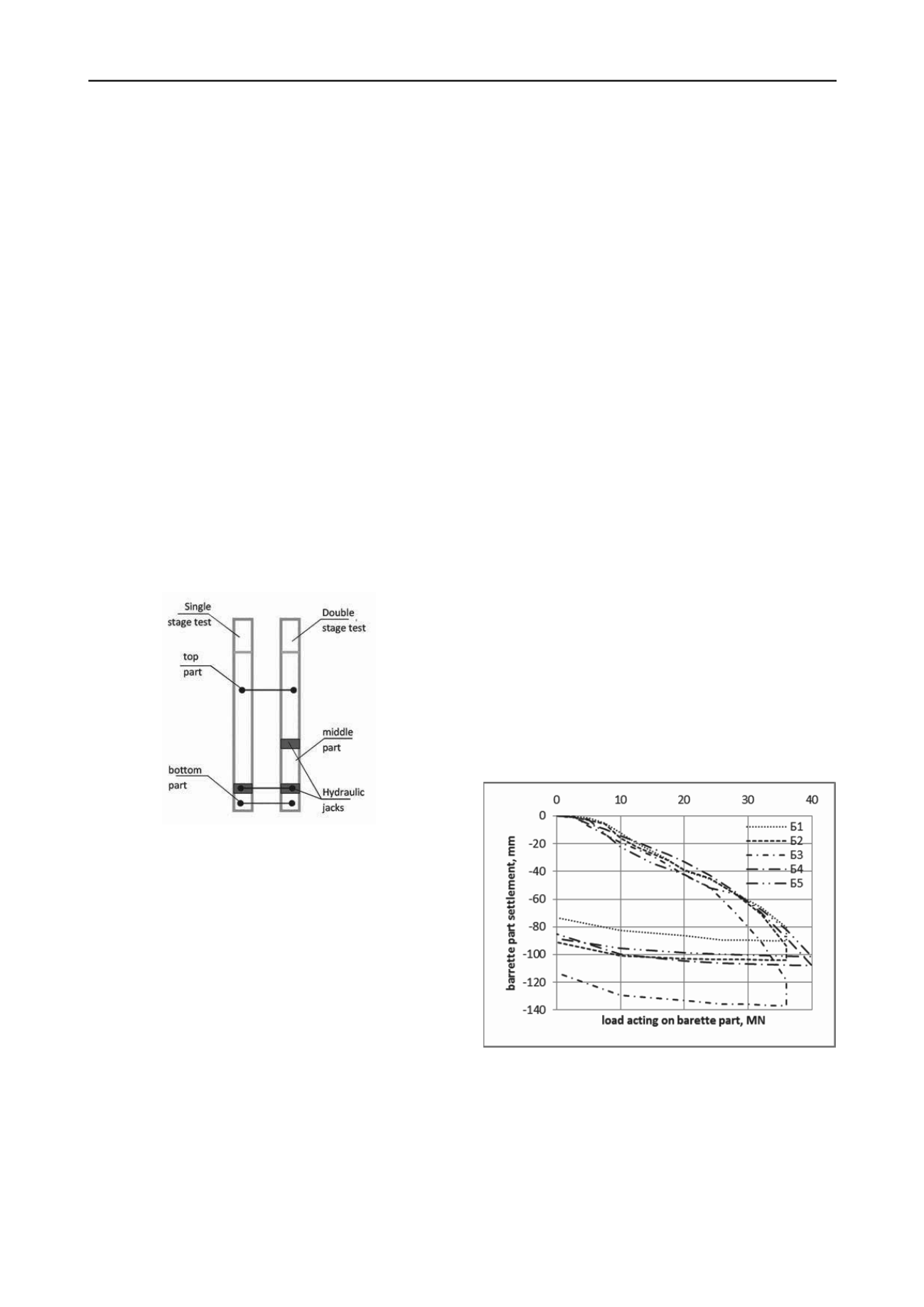

Three of the five tested group barrettes were equipped with

loading device installed in two levels, two single piles in one

level. Single-level and two-level testing scheme and barrette

part nameingare shown in Fig. 2

Figure2. Scheme of barrete parts namings

Barrettes with one level jacks were tested in one phase, the

pile with two levels - in two stages. In the first stage the lower

part of the pile is loaded with the lower level of the jack. In the

second stage the upper jack level creates load on the middle part

of barrette. During a first stage of testing upper level jacks are

closed and load transfer through them is not different from a

solid barrette section. During loading of the upper level, the

hydraulic system of lower jacks is open into atmosphere,

making them closing or opening freely. During the testing of the

upper level when the lower level is open and jacks are retracted,

the entire load of the upper level of loading is transmitted to the

shaft of the barrette middle fragment. As the criteria for test

advancement standard RF deformation stabilization criteria 0.1

mm/h was used. It is 2.5 times more rigorous then the standard

European 0.25 mm/h. Results comparison with two different

stabilization criteria showed, that application of the criterion of

0.25 mm/h underestimates the magnitude of barrete base

displacement by 30%. Choice of stabilization criteria is

especially important when the testing jack located near the

barrette base in clay soils, as in this case, due to soil

consolidation deformation process is much slower.

4 TEST RESULTS

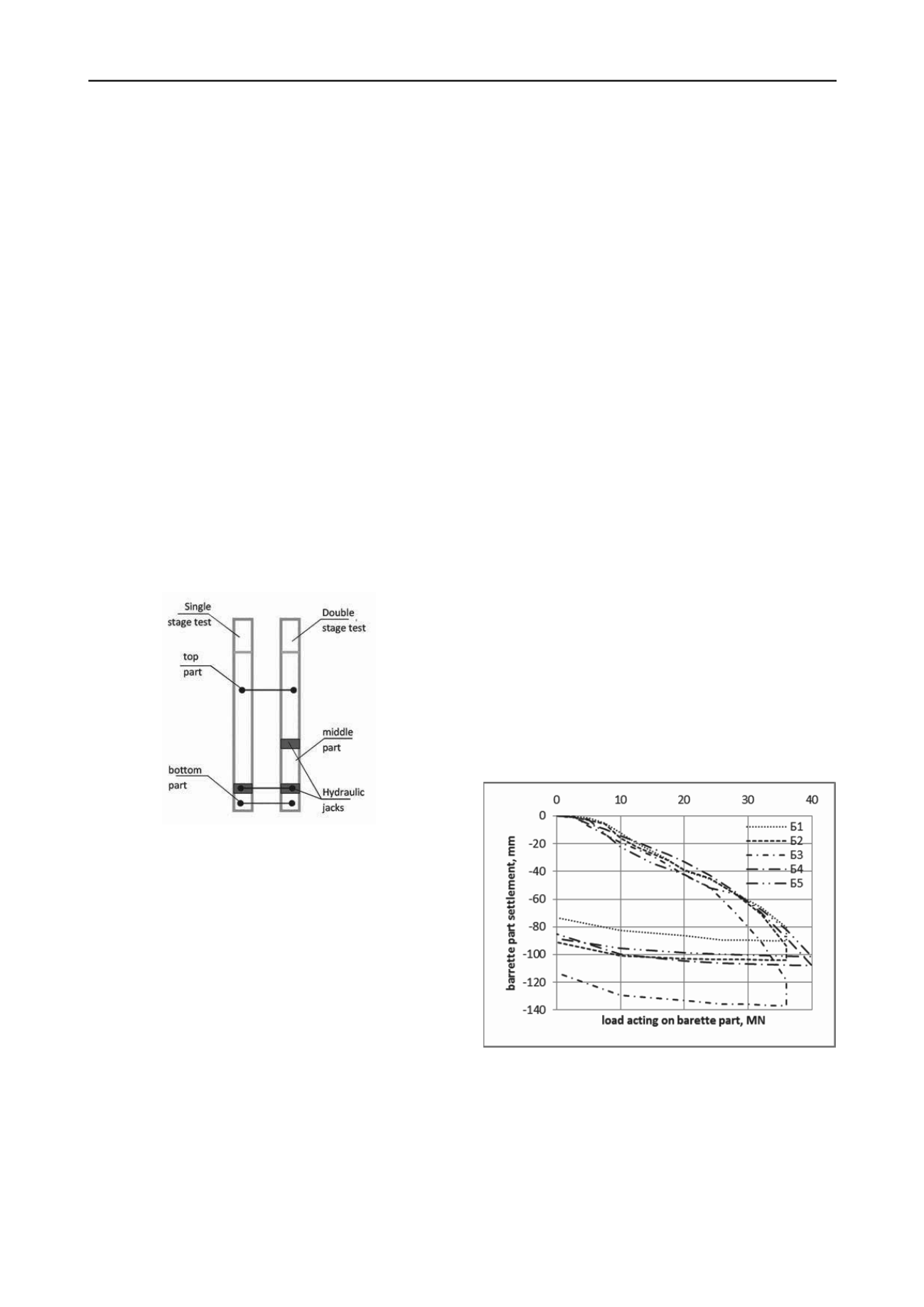

4.1 Test of the lower parts of barrettes B1...B5.

The value of the load reached during first stage of testing

was 40MN and 48 MN for second stage.

Bearing capacity of the lower parts of the test group barrette

was 90% of the bearing capacity for a single barretes test, due to

the group effect.

Load-settlement characteristics for barrettes B1…B5 shown

on Figure 3 and shows that settlement of Barrette B2, located

between Barrette B1 and B3 is 15% more than that of Barrette

B1. This effect is referred to well-known concepts of group

effect in pile groups. Pile settlement in the group always

exceeds the settlement of single pile, and the settlement of

central pile is highest. With the growth of the number of piles in

the group this effect expected to increase. By means of

mathematical modeling of group testing and achieving the same

group effect, which was observed in the trial, one can confirm

the accuracy of the model input parameters, and to validate its

use for the calculation of the entire foundation.

The elastic component of the Barrette B1 ... B5 base

settlement is 13 ... 20%, and the residual inelastic component

reaches 79 ... 87.6% (Fig. 3), i.e. much of the ground under the

base of Barrette undergone plastic deformation.

In the analysis of Fig. 3 it may be seen that load-settlement

characteristics can be divided into several stages. In the first

phase, with a load values up to 5MN, load held by the shaft

friction on the surface of Barrette part, and movement up to 1

mm recorded. At the 2nd stage of loading barrete part is moved

and load being transferred to barrete base. Soil underneath the

barrete disturbed by drilling began to compact under load.

Settlement of barrete base increases linearly with load until

20…40 MN load value is reached. As the barrette part

movement increases, shaft frictions on its side reaches a

maximum value and remain constant to the rest of stage 1. Due

to this effect further increment of load transferred directly to the

barrette base. The final stage is characterized by an increase of

settlement increment per unit increment of load, indicating that

the transition of the ground under the base of barrette to the

plastic state.

Figure 3. Stage 1 test results.

In order to clarify the shaft bearing capacity for bottom part

of Barrette B4, the loading increments in the first stages of the

load testing has been reduced from 5MN to 2.5 MN, which led

to an increase in the number of stages in the load range of up to

20 MN from 4 to 8 . An interesting finding was the fact that,

regardless of the number of stages loading time spent on testing

barrette B4 and B5, was similar and was 277 and 259 hours,

respectively.

Concluding the analysis of bottom level testing one can

mention high repeatability of results, which indicates the