582

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

7

CONCLUSIONS

Soil improvement described in this paper involved stone

columns installed below each tank. The gravel material pressed

into the soft soil is equivalent to a layer of about 30 cm in

thickness. Since the geodetic surveys showed negligible soil

upheaval (a few millimetres), it can be concluded that the soil

improvement prevented equivalent settlement of 30 cm.

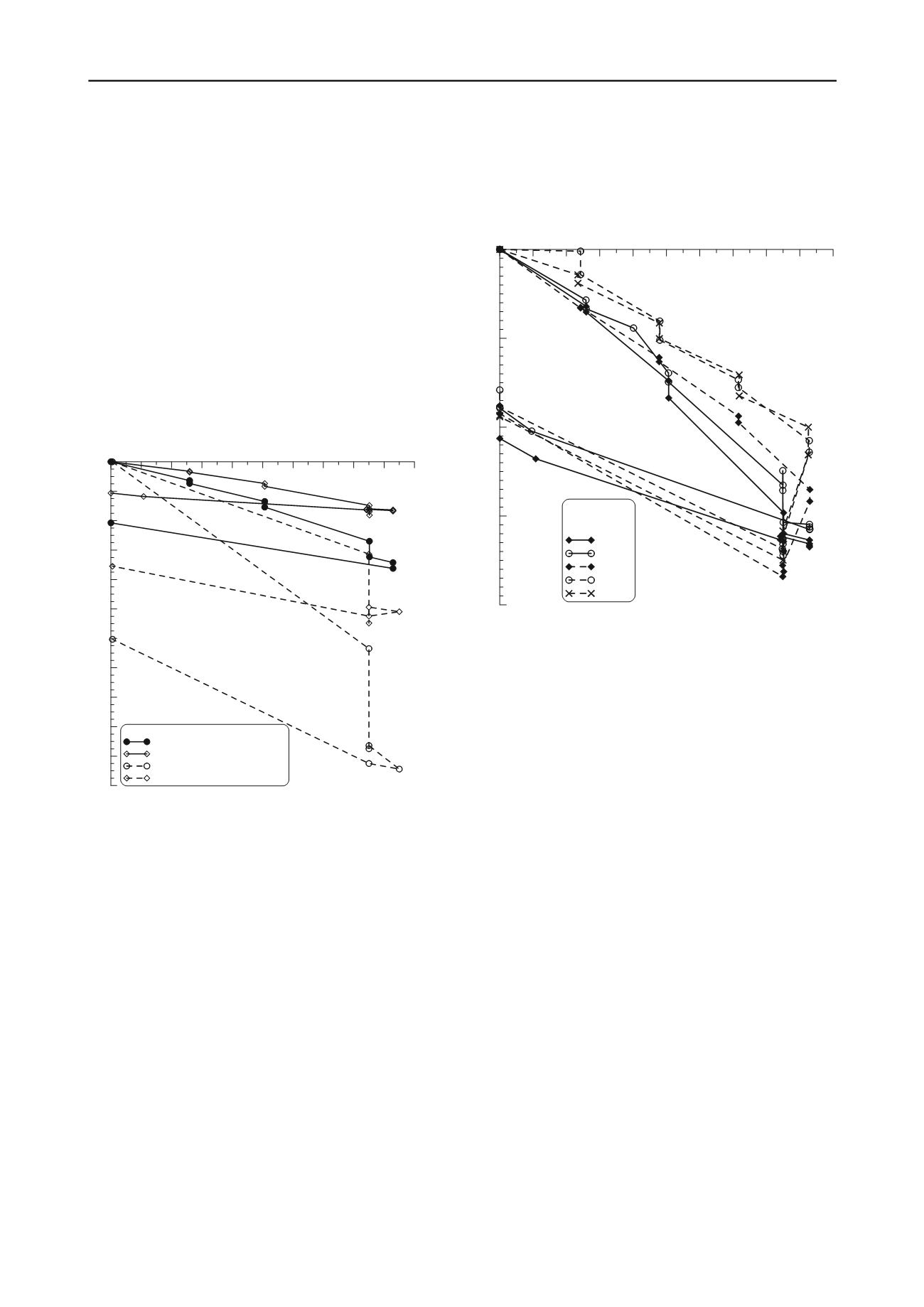

The hydro test showed, as demonstrated in the case of Tank

A-2507, that total settlements are relatively small, i.e. smaller

than estimated by calculation (Figure 6).

For the purpose of comparing actual settlements with those

given in behaviour criteria, the settlements of the tank bottoms

are shown so that displacements corresponding to a rigid body

rotation are given separately from displacements resulting from

non-planar differential settlement. Figure 3 illustrates that the

bedding was mostly displaced as a rigid body, while non-planar

differential settlement was slight. For this reason, it is sure to

say that maximum values of the settlements and their shapes are

within the values required by the relevant standard (Figure 4).

0

20

40

60

80

100

120

140

160

180

200

load [kPa]

-22.0

-20.0

-18.0

-16.0

-14.0

-12.0

-10.0

-8.0

-6.0

-4.0

-2.0

0.0

settlement

[cm]

hydro test for tank A-2507

tank center - measured

tank periphery - measured

tank center - Plaxis - calculated

tank periphery - Plaxis - calculated

Figure 6. A comparison of measured and calculated results of

settlements obtained from the hydro test on Tank A-2507.

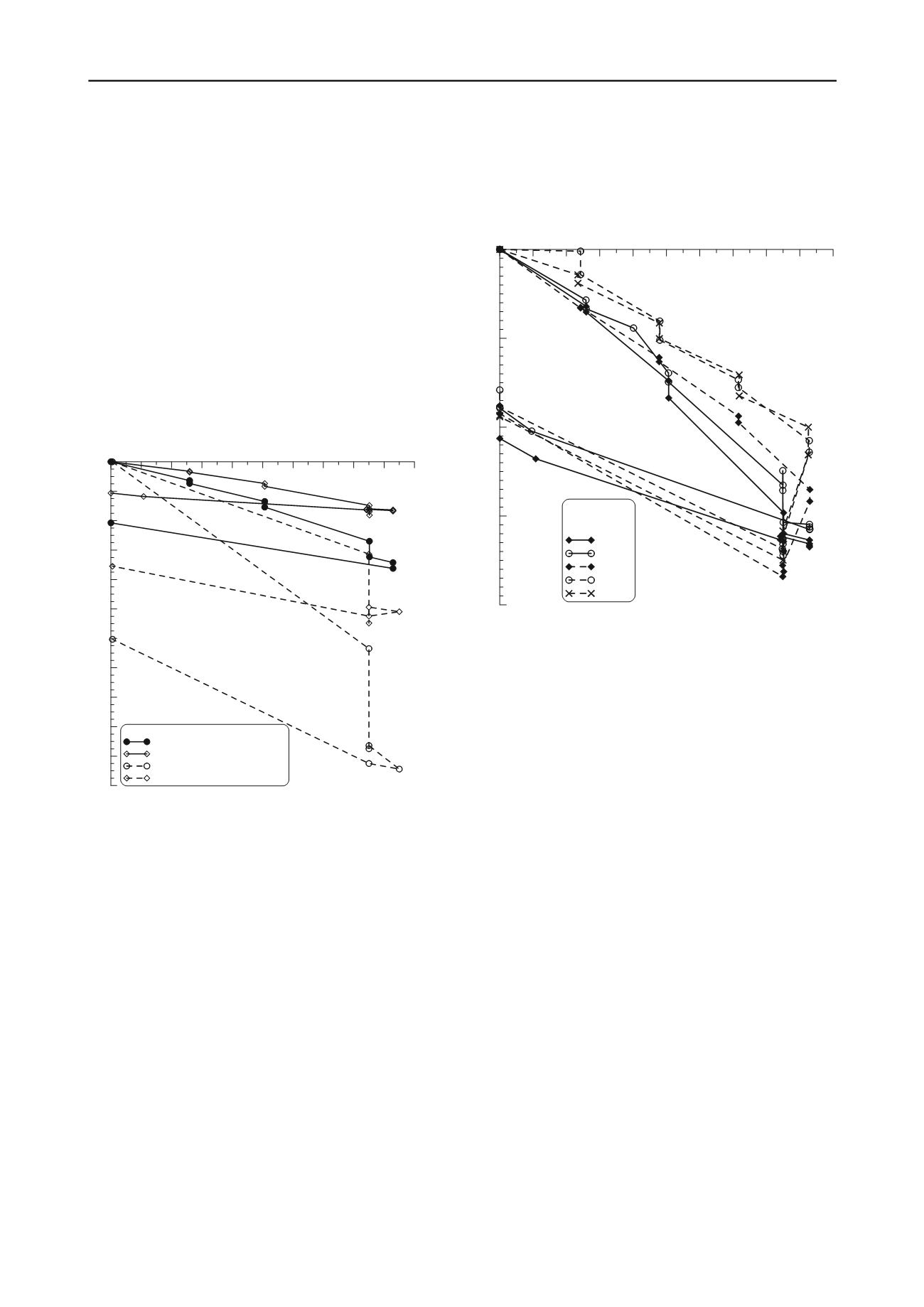

It was found that the settlements, after the tank had been

emptied, were smaller although they had the same shape. This

proves that the deformations after tank emptying are mostly

elastic (Figure 4). As tank loads by crude oil are less than those

by water, it is expected that subsequent displacements at

operating load will be less than those recorded in hydro tests,

and that no further non-planar differential settlement of the tank

bedding will occur. The same goes for the other four tanks

(Figure 7). The diagram of the settlements of all five tanks

shows that such settlements are about the same when the tanks

are subjected to the same load. As this is normally expected in

the case of horizontally stratified soil, this is proof of proper and

correct measurement of displacement.

As seen in Figure 6, the settlements obtained by calculation

were significantly greater than those measured. An explanation

for different values of settlements should be thoroughly

investigated in further numerical analysis which will take into

consideration the fact that columns and soil act together as

recommended in Ambily and Gandhi (2004).

In the case of the Sisak tanks, the hydro tests proved correct

functioning of the floating roofs, watertightness of the shells

and bottoms, and rigidity of the foundation structure for all

tanks.

The strictly applied procedures regarding soil investigation,

design, hydro test and exploitation ensured safety in execution

and further use. Considering the safety risks and loss of

investment in case of non-allowable differential settlements of

the soil, it is clearly understandable, yet in some cases

disregarded, why such procedures must be applied.

The data collected about the behaviour of the tanks during

the hydro tests were well documented and could be used to

improve design of tanks.

0

20

40

60

80

100

120

140

160

180

200

load [kPa]

-4.0

-3.0

-2.0

-1.0

0.0

settlement [cm]

hydro test -

tank periphery

- measured

A-2507

A-2508

A-2509

A-2510

A-2511

Figure 7. Total settlements of tank perimeters during hydro tests

performed on all five tanks

8

ACKNOWLEDGEMENTS

The writers particularly wish to thank Z. Korica and M. Bago

for their support and assistance.

9

REFERENCES

Ambily, A.P.& Gandhi, S.R. 2004. Analysis of hydro test results for

steel tank on stone column improved ground. Proceedings of the

Indian Geotechnical Conference held at NIT Warangal, 420-423.

API-650: American Petroleum Institute (API) standard 650: ”Welded

tanks for oil storage”.

API-653: American Petroleum Institute (API) standard 653: “Tank

Inspection, Repair, Alteration, and Reconstruction”

Bell, R.A. & Iwakiri, J. 1980. Settlement comparison used in tank-

failure study. Journal of the Geotechnical Engineering Division

106, GT2, 153-169.

Berardi, R. & Lancellotta, R. 2002. Yielding from field behavior and its

influence on oil tank settlements. Journal of geotechnical and

geoenvironmental engineering 5, 404-415.

EN 14015:2004, Specification for the design and manufacture of site

built, vertical, cylindrical, flat-bottomed, above ground, welded,

steel tanks for the storage of liquids at ambient temperature and

above

Marr W.A., Ramos J.A. & Lambe T.W. 1982. Criteria for settlement of

tanks. Journal of the Geotechnical Engineering Division 108, GT8,

1017-1039.

Raju, V.R., Hari Krishna, R. and Wegner, R. 2004. Ground

improvement using Vibro Replacement in Asia 1994 to 2004 – a 10

year review, Proceedings of 5th Int. Conf. on Ground Improvement

Techniques, Kuala Lumpur, Malaysia.