579

The use of hydro test results for design of steel tanks on stone column improved

ground - a case history

L’emploi des résultats des essais hydrauliques dans l’étude des réservoirs en acier sur le sol

amélioré par colonnes de pierre – histoire de cas

Matešić L.

Geokon-Zagreb, Zagreb, Croatia; University of Rijeka, Faculty of Civil Engineering, Rijeka, Croatia

Mihaljević I., Grget G.

Geokon-Zagreb, Zagreb, Croatia

Kvasnička P.

University of Zagreb, Faculty of Mining geology and petroleum engineering, Zagreb, Croatia

ABSTRACT: This paper describes hydro tests performed on five large storage tanks (80.000 m

3

each) located at the Sisak Oil

Terminal, Croatia. Because of its small stiffness and low water permeability, foundation soil for each tank was improved with 660

stone columns. In order to reduce the risk of accidents, such as fire, breach or leak, a crude oil storage tank requires stringent security

measures. In the case of the Sisak tanks, the hydro tests were conducted as part of technical monitoring to determine a set of

documented and interconnected activities which would provide proof of proper functioning of all elements of a tank structure. In case

of critical deviations from the operation expected, such activities ensure that such deviations are removed or corrected on time by

taking necessary measures approved by experts. Under a procedure for the hydro tests, the phases of tank and bund filling were

defined and each phase was followed by visual inspection and measurements of settlements and deformations of the steel structure.

Design directions for future foundation and hydro tests of tanks were made accordingly.

RÉSUMÉ : Les essais hydrauliques conduits sur cinq réservoirs de grande taille (chacun de 80,000 m3 ) situés dans le Terminal

pétrolier de Sisak en Croatie, sont décrits dans l’ouvrage. Compte tenu de petite rigidité et perméabilité à l’eau peu importante, le sol

de fondation pour chaque réservoir a été amélioré avec 660 colonnes de pierre. Les mesures très rigoureuses doivent être prises pour

les réservoirs à pétrole brut afin de réduire le risque d’accidents tels que feu, rupture ou fuite de pétrole. Dans le cas des réservoirs de

Sisak, les essais hydrauliques ont été conduits dans le cadre de la surveillance technique dont le but était de définir une série des

activités bien documentées et interconnectées visées à prouver le fonctionnement impeccable de tous les éléments structurels du

réservoir. Dans le cas d’une déviation critique par rapport au fonctionnement normal, ces activités permettent l’élimination ou la

correction prompte de ces déviations en prenant les mesures appropriées approuvées par les experts. Dans la procédure pour les essais

hydrauliques, les phases de remplissage du réservoir et de la cuvette de rétention ont été définies, et chaque phase a été suivie par une

inspection visuelle et par mesurage du tassement et des déformations de la construction en acier. Les instructions d’études sont

fournies pour les essais hydrauliques et les essais des fondations futurs.

KEYWORDS: steel tank, stone columns, hydro test, monitoring, settlement

1

INTRODUCTION

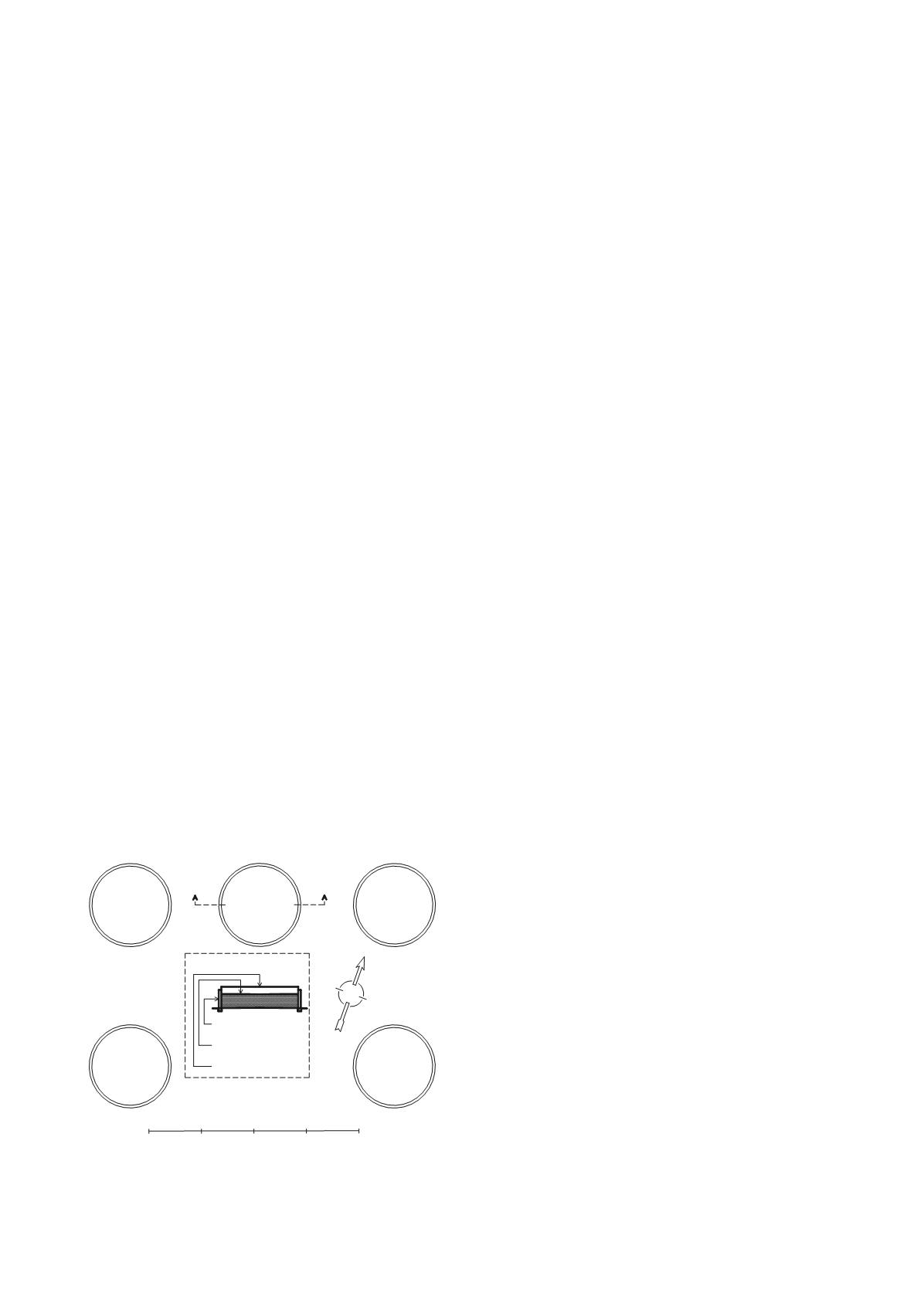

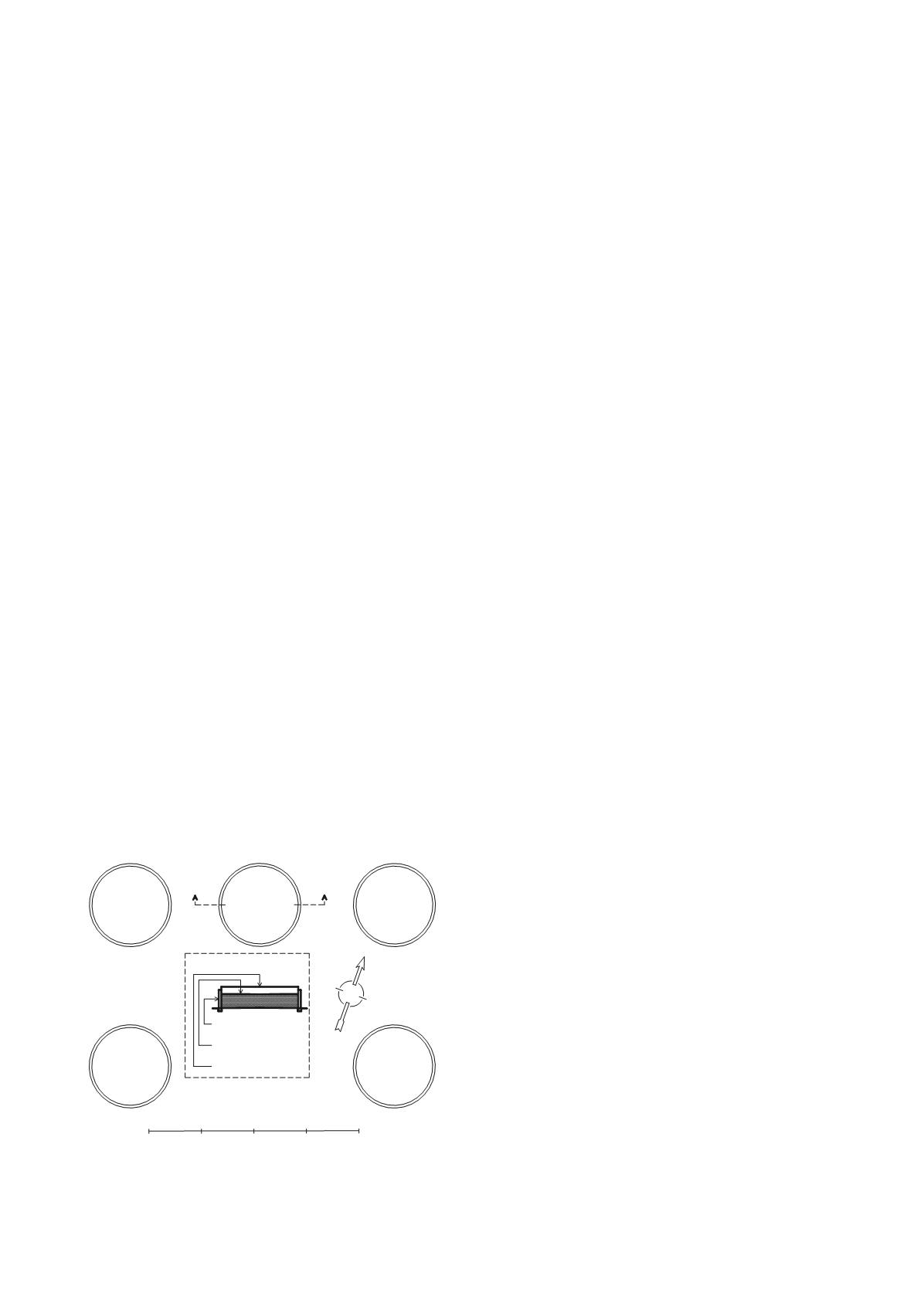

During the years 2010 and 2011, five new crude oil storage

tanks were built at the Sisak Oil Terminal.

80.000 m

A-2510

N

50

100

150

200 m

0

3

80.000 m

A-2509

3

80.000 m

A-2508

3

80.000 m

A-2507

3

80.000 m

A-2511

3

A

A

cross section A-A

bund

floating roof

tank

Figure 1. The layout plan of the tanks

All the tanks are of the same size and have an identical steel

structure with a floating roof and steel bund wall designed in

accordance with API 650. The diameter of the tanks and bunds

is 73,2 m and 78,2 m respectively. The tanks have 80.000 m

3

in

volume and their total and overflow height is 20,6 m and 19,5 m

respectively (Figure 1.).

Foundation soil is horizontally stratified and, therefore, the

soil under all the tanks is of almost the same properties. Because

of its small stiffness and low water permeability, the foundation

soil for each tank was improved with hundreds of stone

columns, which is a technology applied in similar cases of soil

improvement (Raju et al 2004, Ambily and Gandhi 2004).

In order to prevent industrial accidents, viz. fire, breach or

leak of a tank, etc. to happen, a crude oil storage tank requires

special safety measures. For this reason, all tank development

stages such as ground investigations, design, construction,

hydro tests and exploitation, were strictly controlled according

to a highly elaborated plan as laid down in API 653 and EN

14015.

On the basis of in situ and laboratory tests, a numerical

model was created in Plaxis, and all phases of hydrostatic tests

were checked before testing.

2

DESIGN REQUIREMENTS

In the near vicinity of the new tanks, three 80.000 m

3

tanks with

floating roofs were installed 30 years ago. During the hydro test

performed on one of them, the yielding of foundation soil