576

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

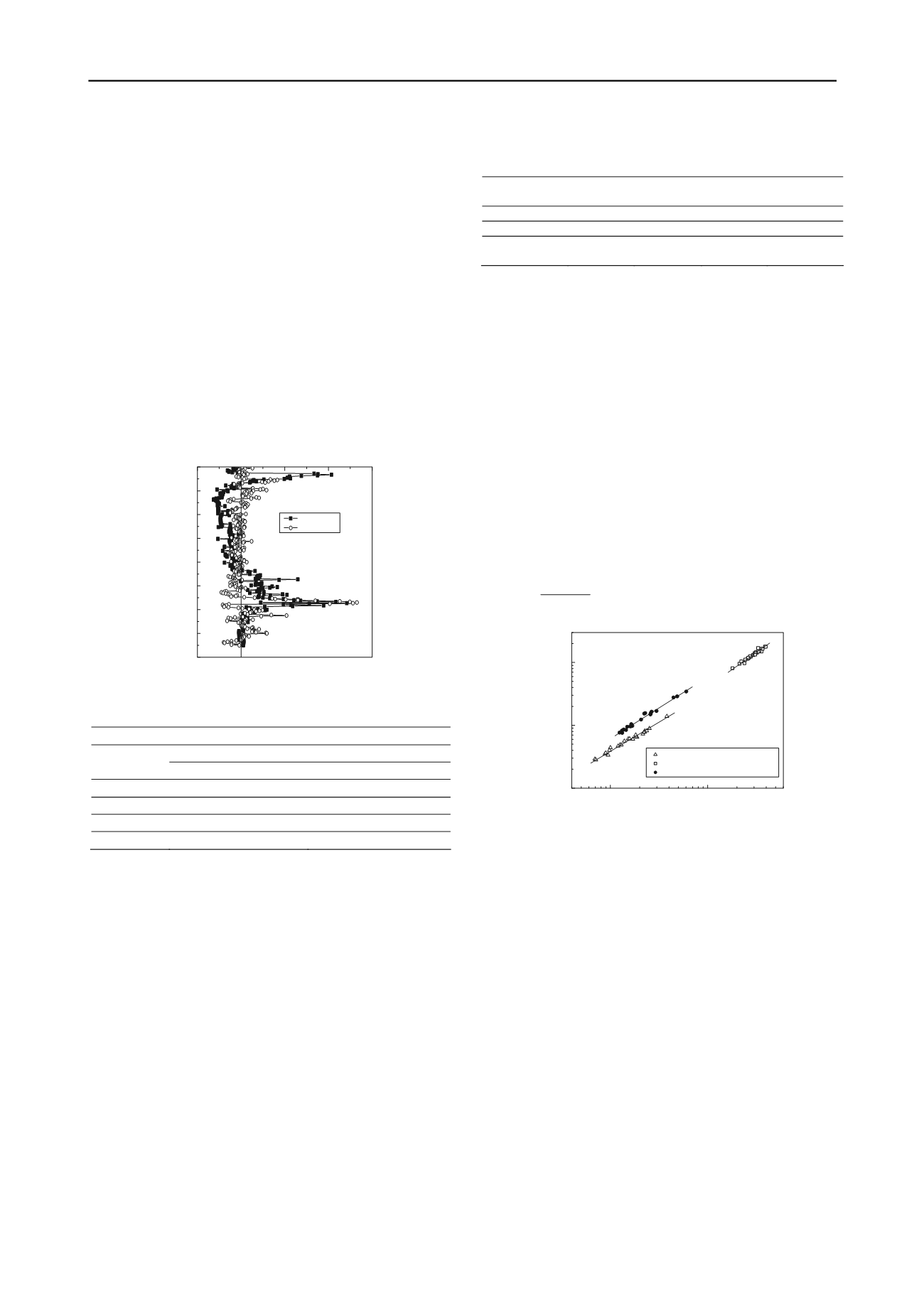

ground surface at different sites were measured and the

difference of elevation may be considered.

To quantify the differences between CPT and CPTU

measurements, the ratios of the CPTU to CPT cone resistance

and sleeve friction measurements were calculated for each site.

The reference line positioned at an average CPTU to CPT ratio

equal to one in the plots of average ratios represents the

theoretical value if soil variability was eliminated and if there

was no effect of cone size. In general, the ratios of cone

resistance and sleeve friction measurements fluctuate near one,

and the measured values increase with depth. For the soft clay

sites (Figure 1), the average fs ratio of the friction sleeve is

always significantly greater than the average qc ratio. For the

topsoil such as fill and silty clay, the ratios CPTU to CPT

fluctuate drastically. The relationships of derived key

parameters are developed between China CPT and international

CPTu (Table 1). From the perspective of engineering practice, it

is concluded that

q

t

= 1.03

q

c

,

f

s

-

CPTu

= 1.05

f

s

-

CPT

. The

empirical equation can be used as useful engineering tool to

guide use of 10 cm

2

international CPTu in China.

16

14

12

10

8

6

4

2

0

0

1

2

3

4

Depth/m

Coneresistance

Sleevefriction

AverageofCPTU/CPTratios

Figure 1. Statistical analysis of

q

c

and

f

s

ratios

Table 1. Conversion relationships between CPTu and CPT parameters.

Soil types

Regression equation

Cone resistance

Sleeve friction

Soft clay

q

t

= 1.04

q

c

f

s-CPTU

= 1.01

f

s

-CPT

Clay

q

t

= 1.02

q

c

f

s-CPTU

= 1.07

f

s

-CPT

Stiff clay

q

t

= 1.01

q

c

f

s-CPTU

= 1.06

f

s

-CPT

Silt

q

t

= 1.03

q

c

f

s-CPTU

= 1.06

f

s

-CPT

Silty sand

q

t

= 1.03

q

c

f

s-CPTU

= 1.03

f

s

-CPT

3 EVALUATION OF ENGINEERING

CHARACTERISTICS BASED ON CPTU TESTS IN CHINA

3.1 Stress history

Since the advent of CPTU in geotechnics, nearly 20 different

methods have been suggested for interpreting the

preconsolidation pressure and the overconsolidation ratio of

clays (Mayne 1991). In this study, the three sites with all

sensitive clay deposits in Jiangsu province of eastern China are

selected (Liu et al., 2007). These Quaternary clay deposits are

located at Lianyungang, Changzhou and Nanjing respectively.

Whenever possible, the OCR values interpreted from various in

situ tests were compared with the oedometer values for

Lianyungang marine clay. At the other test sites, in addition to

oedometer results, some field OCR values were deduced from

field performance observation of trial embankments. These field

values provide a reliable basis for evaluating the validity of the

various interpretation methods in Jiangsu clays. Table 2

presents a summary of the typical property values of the soil

layers.

Table 2. Typical property values of the soils.

Site

Soil type

Water

content/%

Liquid

limit

Plasticity

index

Lianyungang

muck

79.6

75.6

35.8

Changzhou

clay

23.5

41.8

19.0

Nanjing

mucky

silty clay

41.4

36.4

13.3

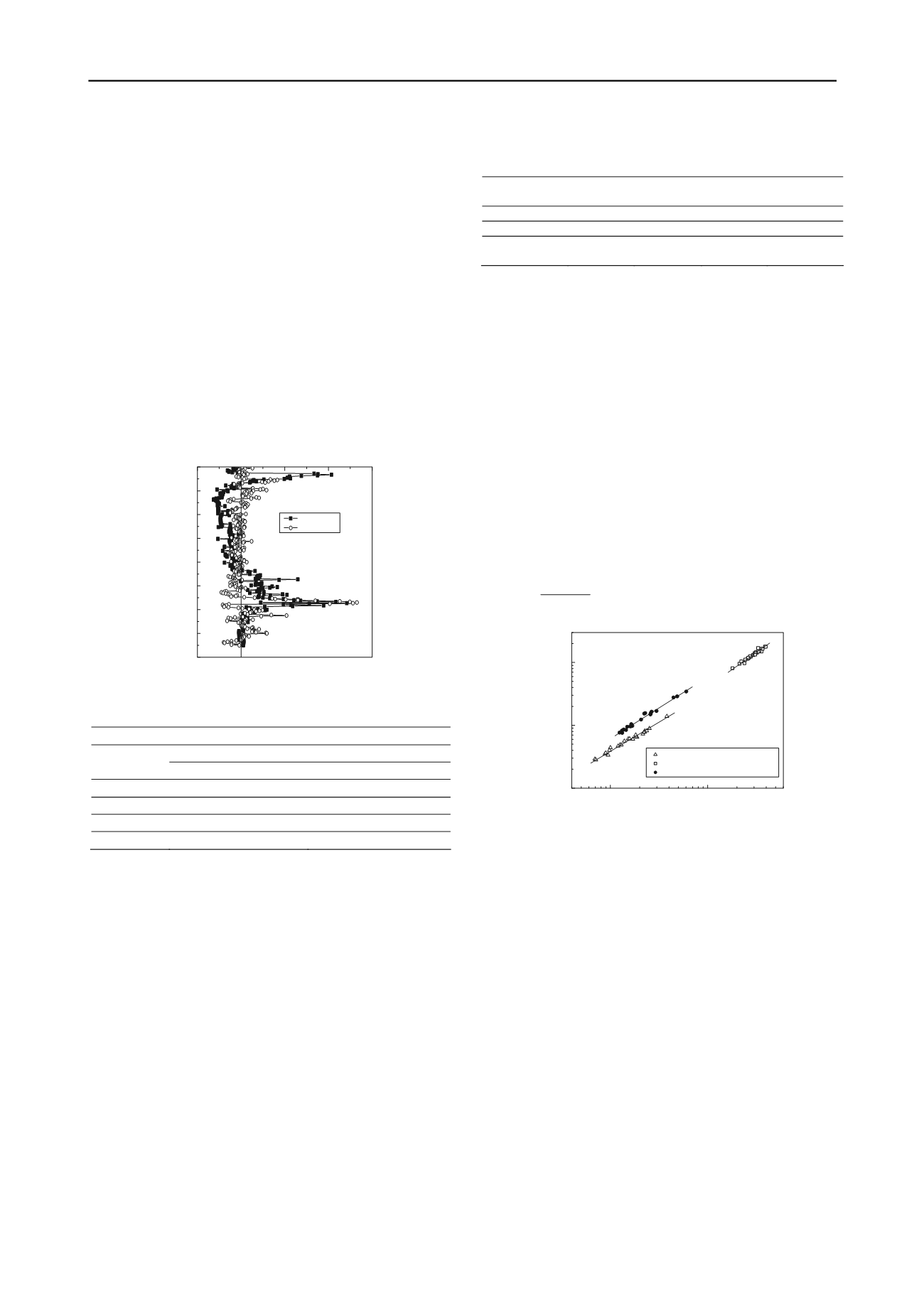

Figure 2 shows the relationship between net tip resistance

(

q

t

–

σ

vo

) and the preconsolidation pressure (

σ

`

p

) measured in the

laboratory oedometer test on high-quality samples. Here, n as

shown in Fig. 1 is the number of data available. In Lianyungang

marine clay deposits, the correlation is excellent (

r

2

= 0.99) for

all the data, and the preconsolidation pressure varies between 29

and 139 kPa. In Changzhou clay site, the correlation is good (

r

2

= 0.95) for the data, and the preconsolidation pressure varies

between 812 and 1789 kPa. It can be seen from Figure 5 that the

relationship between net tip resistance and the preconsolidation

pressure of Nanjing clay site is also pretty good (

r

2

= 0.98).

Consequently, we can obtain the value of Nσt factor, which is

equal to 2.7 according to the correlation relationship for

Lianyungang lightly overconsolidated clay. Similarly, for

Changzhou lightly to moderately overconsolidated clay, the

N

σt

factor is 2.2. For Nanjing backswamp clay deposit, the

N

σt

factor is 2.5. Consequently, the equation defining the correlation

of Lianyungang marine clay site can be expressed as follows:

7.2

0

'

v

t

p

σ q σ

(1)

100

1000

10

100

1000

'

p-oed

/ kPa

( q

t

-

v0

) / kPa

Li anyungang( n=24, r

2

=0. 99)

Changzhou( n=28, r

2

=0. 95)

Nanj i ng( n=20, r

2

=0. 98)

Figure 2. The relationship between preconsolidation pressure measured

in oedometer test and net tip resistance

3.2 Deformation modulus

The one-dimensional constrained modulus, M, as measured in

an oedometer test, has been expressed in terms of a coefficient,

αm, and cone resistance:

cm

q M

(2)

where

α

m

is a correlation factor. In practice, it has been

usual to correlate the modulus

M

to a penetration resistance. To

estimate one-dimensional constrained modulus

M

, the

correlation with net cone resistance (

q

t

-

σ

v0

) is used in the form

(Kulhawy and Mayne, 1990):

8.25

8.25

n

t

M q

q

vo

(3)

Comparisons between M from CPTU with laboratory

oedometric modulus for various types of soil proposed by

Kulhawy and Mayne (1990) showed that the ratio M -

CPTU

/ M -

lab

could equal to 2.21 for high-plasticity clays and silty soils. In

Figure 3 the constrained modulus estimated with relationship

(3) is plotted against that determined by laboratory oedometric

tests, carried out on all the types of Jiangsu lagoonal soils. In

our case, the ratio M-

CPTU

/M-

lab

is always greater than the unity

and is not influenced by the type of soil or by its cone resistance

value (Cai et al. 2010).