196

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

0.0

0.2

0.4

0.6

0.8

0.0 0.2 0.4 0.6 0.8

Normal stress (MPa)

Shear stress (MPa)

CP1

CP2

STV1: dmax=40mm

STV2: dmax=160mm

De Mello's fitting

Prediction for CP2 &

STV2

The problem of estimation of the at rest coefficient K

o

for

overconsolidated soils is treated by Bohac et al. (2013). At a site

containing highly overconsolidated clays, K

o

was measured by

using Marchetti (1980) flat dilatometer. The K

o

values are

higher than those estimated from oedometer yield point and

empirical correlations by Main and Kulhawy (1982). Numerical

modelling of the flat dilatometer penetration into the soil based

on a

hypoplastic model (Mašín, 2005)

combined with the

intergranular strain concept proposed by Niemunis and Herle

(1997) were also performed. However the K

0

values are slightly

underpredicted.

5 CRUSHABLE GRANULAR SOILS

The significance of particle crushing to the mechanical

behaviour of granular materials has been well identified and in

the particular field of geomechanics, it is recognized as having a

major effect in a wide range of practical problems involving

shallow foundations, bearing capacity of piles, stability of earth

structures, seepage properties, hydraulic conductivity, and pore-

pressures distribution in earth dam water retaining structures,

pavement and railway substructures. However, the laboratory

investigation and interpretation of crushable materials show

some inherent difficulties and there is a need for consideration

of appropriate approaches that may differs from non-crushable,

cohesionless sands. In this respect, Wils et al. (2013) identify

and analyse several issues like: determination of the minimum

and maximum density, sieving and the need for advanced grain

morphology characterisation by means of microscopy, the

abrasion of particles and the apparent cohesion due to

interlocking of the angular particles creating sand clusters with

the appearance of larger particles, as well as the existence of

larger shells sheltering smaller grains.

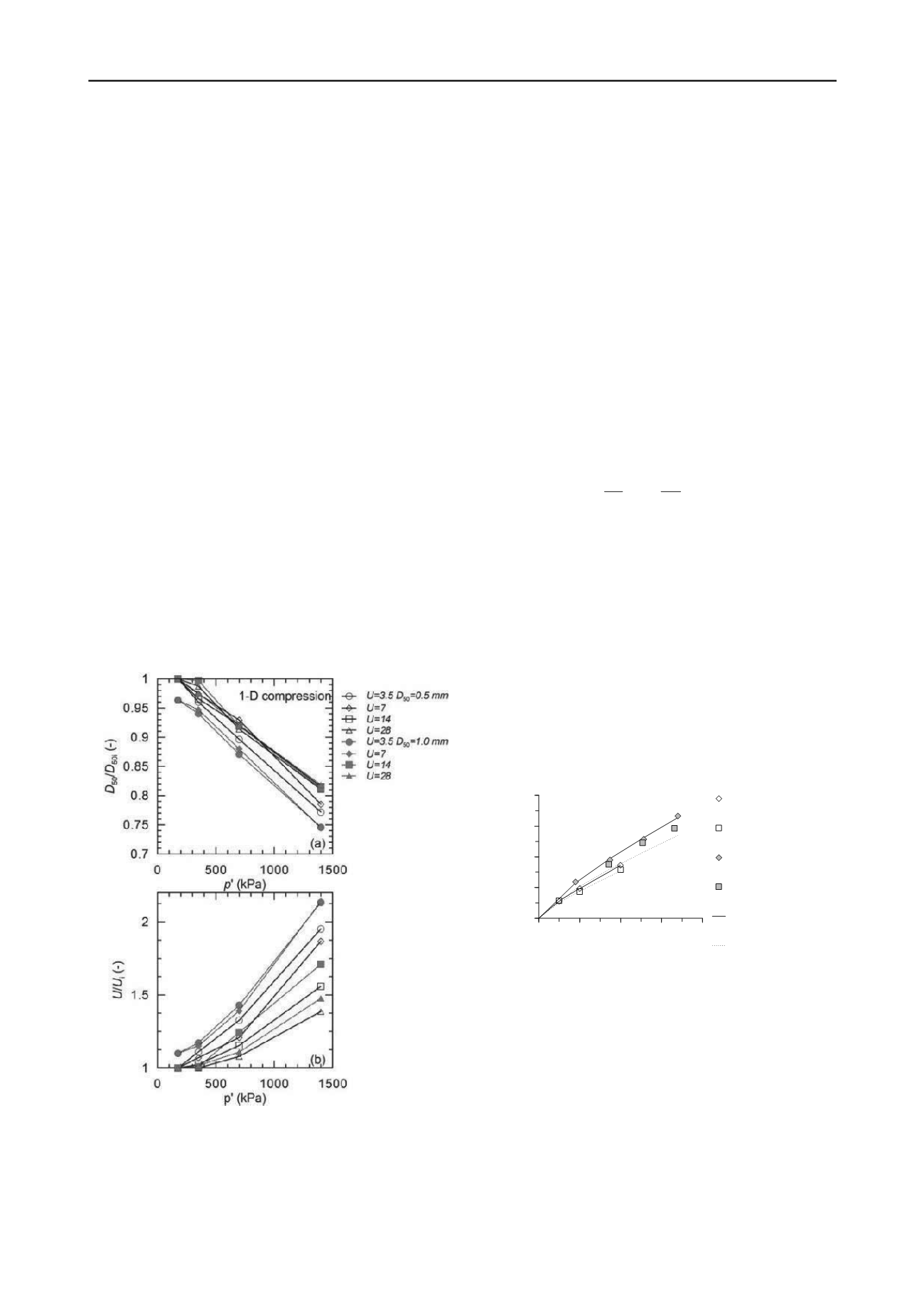

Figure 14. Evolution of ratios: (a)

d

50

/

d

50i

and (b)

U

/

U

i

with mean

effective stress applied in 1D-compression (Casini et al. 2013).

An experimental investigation into the mechanical response

of an artificial granular material, consisting of crushed

expanded clay pellets, LECA (Light Expanded Clay Aggregate)

under various stress path tests is conducted by Casini et al.

(2013). The material was reconstituted, with a maximum

particle size of 2 mm, into grading curves with the same mean

diameter, d

50

, and different coefficients of uniformity, U (= 3.5,

7, 14, 28) or the same U and different d

50

(= 0.5, 1mm).

Changes in of the grading at the end of the tests (one

dimensional, isotropic and triaxial compression) were described

using two parameters defined as the mean diameter and

coefficient of uniformity of the final distribution over the values

of the initial distributions,

d

50

/

d

50i

and

U

/

U

i

, respectively. Poorly

graded samples show more pronounced decrease in mean

diameter and increase of uniformity with higher applied stresses

(Figure 14).

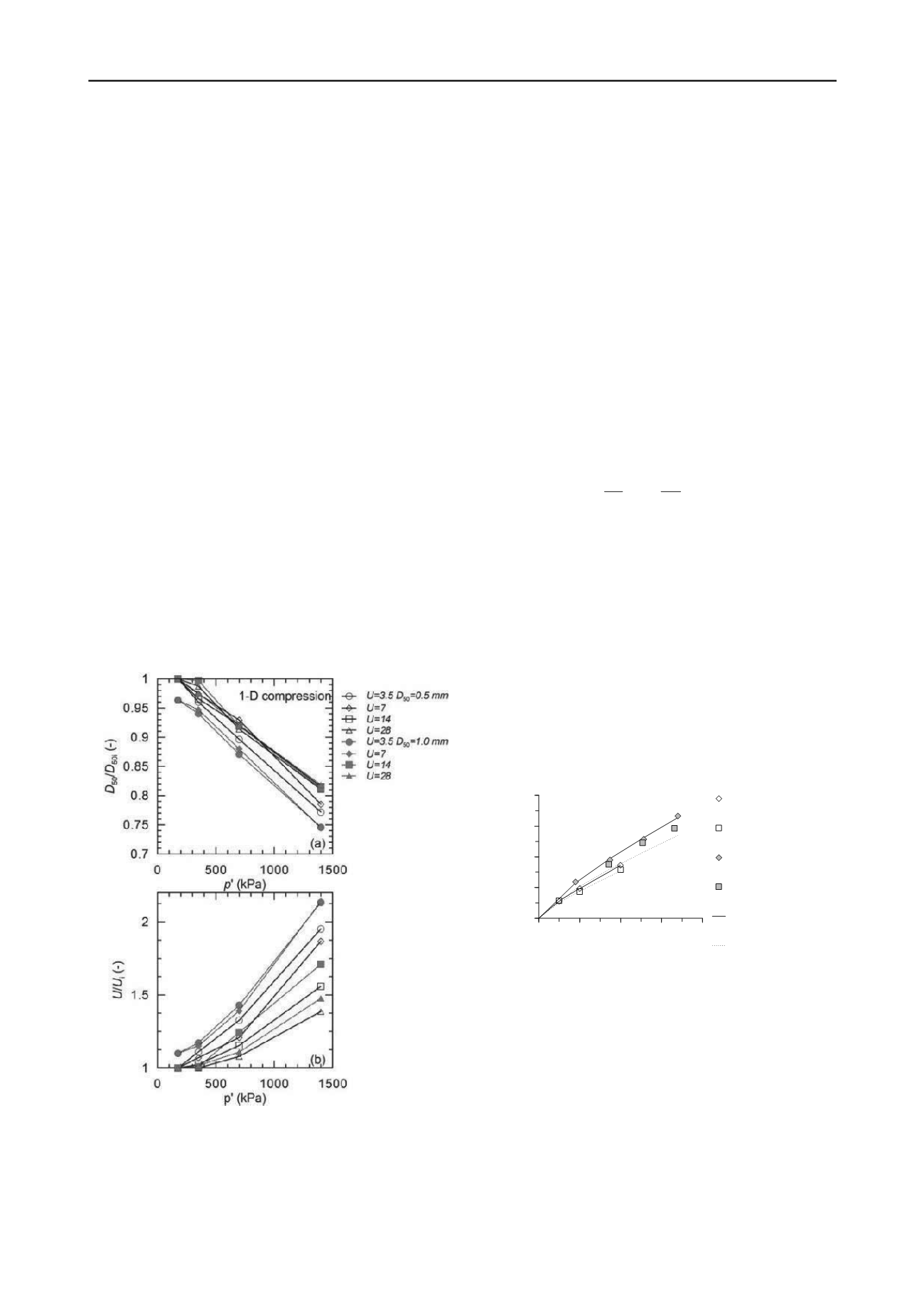

Experimental evidence of size effects in rockfill shear

strength and the link with the crushing strength of rock

aggregates is presented by Frossard et al. (2013). Compression

test results on individual chalk (CP) and quartz rock (STV)

particles have been statistically analysed and it was shown that

the probability of survival for each grain size fraction follows

Weibull distribution given by:

(3)

where

o

is the value of the strength of d

o

size particles such

that 37% of the total number of tested particles survive. The

exponent m is called the Weibull modulus, which increases with

decreasing variability in strength of the material. For each

material, drained triaxial tests on dry samples (maximum

particle diameter sizes of 40mm (CP1 and STV1) and 160mm

(CP2 and SV2)) under different confining presures were

performed. Considering that individual particle breakages affect

the shear strength of the entire granular medium, a method to

predict the effects of scale on shear strength envelopes of

rockfills is proposed. Figure 15 shows the comparison between

measurements and predictions for shear strength envelopes for

both CP2 and STV2 materials, based on the best fit of CP1 and

STV1 data with the failure envelope given by De Mello (1977)

(

=A.

n

b

).

Figure 16. Scale effect on shear strength (Frossard et al. 2013).

Investigations performed by Shahnazari et al. (2013) on the

mechanical behaviour in triaxial apparatus of two calcareous

natural soils obtained from the Persian Gulf, Hormuz Island

sand (HI) and Bushehr Port sand (BP) (Figure 16), and

comparison with the triaxial response of a silica sand, Firoozkuh

(F) showed behavioural contrast between the sand materials,

and through global measurements, clear evidence of particle

breakage of the former soils.

Results from a series of basic characterisation tests

conducted on reconstituted samples of carbonate sand to

understand its behaviour are reported by Safinus et al. (2013).

Compared to silica sand, carbonate sand has considerably

higher angularity, lower grain hardness and higher intra-particle

m

o

n

o

s

d

d

d

dP

exp