187

Special Lecture /

Conférences spéciales

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

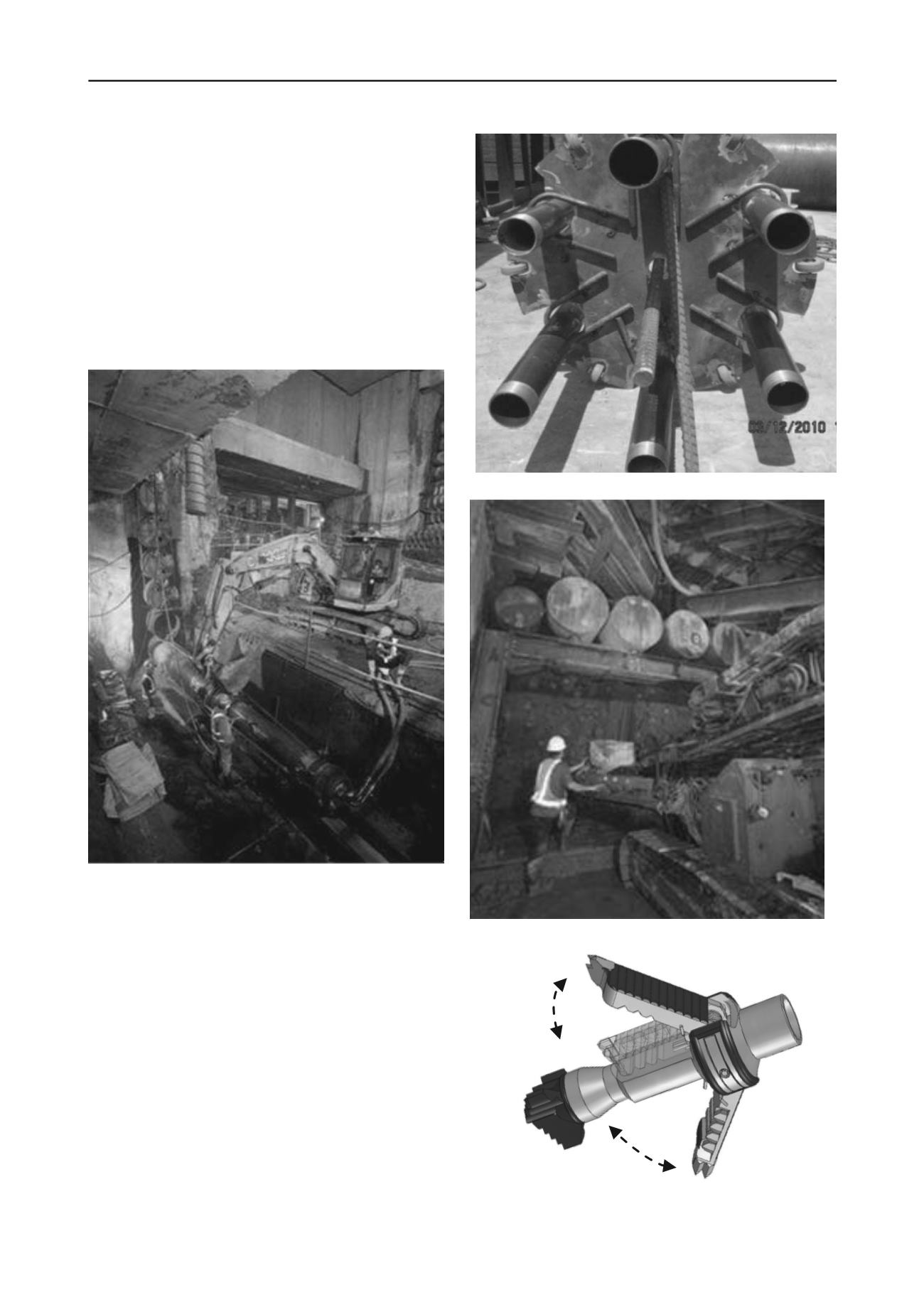

walls were installed after a complex phase of works (bulk

excavation, soil treatment, micropiles, Berlin wall, and

strutting).

Soletanche Bachy had been aware of the presence of old

king posts which had been used as temporary supports during

the construction of the 1985 station and left in place. The

accurate position of these obstructions were unknown and a

detailed working procedure for the removal of these

obstructions was put in place covering safe access lighting and

air supply. When a King Post was encountered during pipe

ramming, the auger was used to clean the pipe and the steel

profile exposed. Following strict safety procedures, a worker

was sent into the pipe to clean around the profile and it was then

cut into smaller pieces for removal back through the pipe.

Figure 13. Pipe jacking and mining – South Wing.

Under the station, all the pipes were driven to the existing

diaphragm walls and had to be anchored into them. The initial

design indicated the pipes being driven 500mm into the

opposing wall. However, as well as the impracticalities of doing

so, the Authorities had rejected this scheme through concern for

damage to the existing structure.

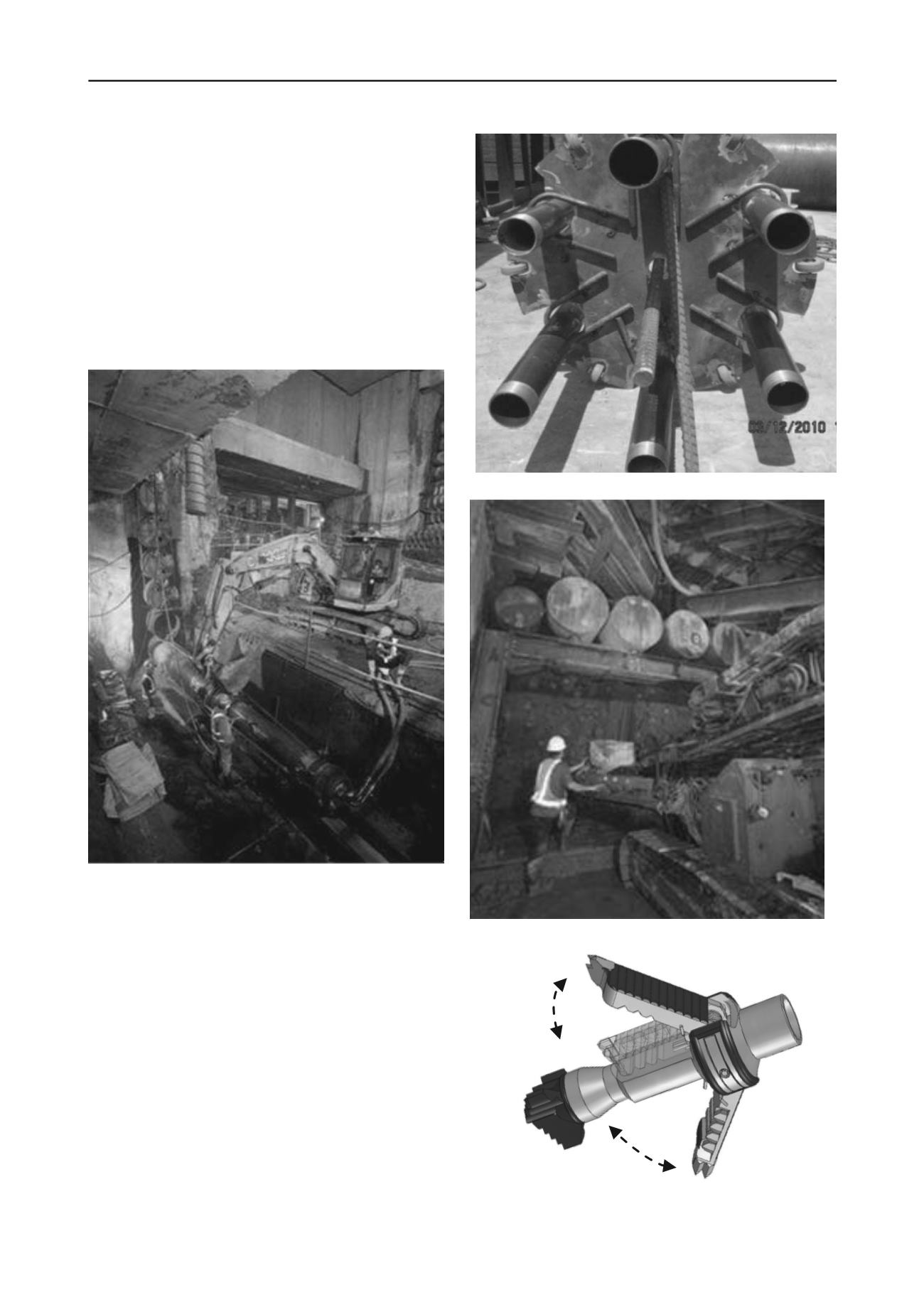

Soletanche Bachy proposed to tie in the pipes, using drilled

reinforcement bars. An innovative system was developed by

Soletanche Bachy. A guide was fabricated and inserted into the

pipe. This guide was positioned at the end of the pipe up against

the opposing wall and cores were then drilled into the

diaphragm wall using the guide to ensure accurate positioning

of the dowel bars which were sealed using an adhesive capsule.

Figure 14. The “Gun” for the Ø600 pipes.

Figure 15. Drilling in the soil nails using the Springsol.

Figure 16. The Springsol tool, unfolded.