197

Technical Committee 101 - Session I /

Comité technique 101 - Session I

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

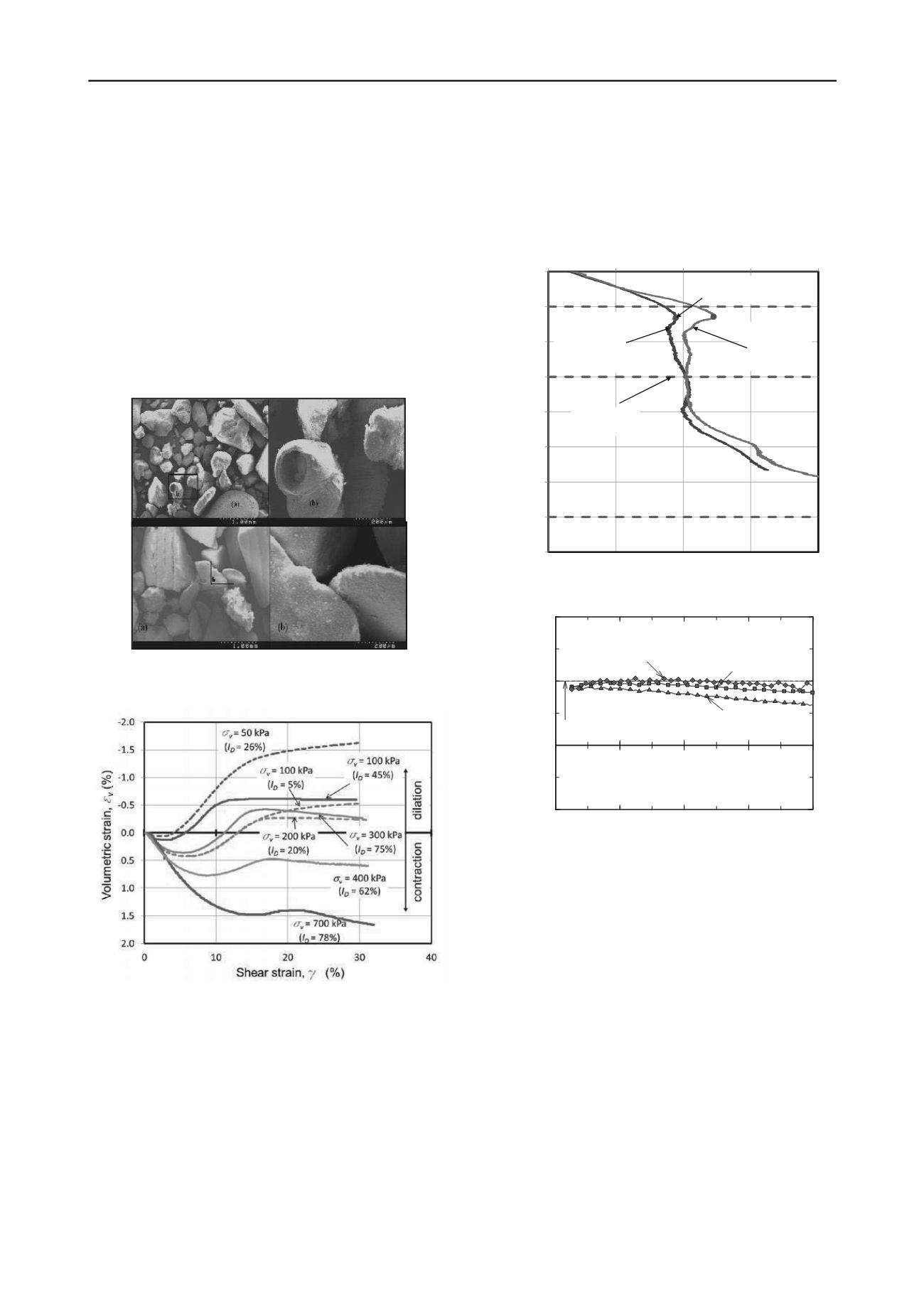

porosity, which result in high friction angles and

compressibility. The corresponding dilatancy is affected

strongly by the confining stress (Figure 17): even for low

relative densities, dilation occurs at low confining stresses,

reflecting the greater particle interlocking compared to silica

sand, while with the increase of confining stress, the dilatancy is

suppressed quickly, and finally diminishes completely at a

relatively low stress level, due to particle degradation. The

influence of the observed characteristics of carbonate and silica

sands on practical applications was examined through model

tests in drum centrifuge of spudcan foundations penetrating

through four-layer soils, with a carbonate or silica sand layer

interbedded in soft clay. All measures of spudcan punch-

through severity were significantly lower for interbedded

carbonate sand despite its higher friction angle (

crit

= 40

)

compared to silica sand (

crit

= 34

), Figure 18.

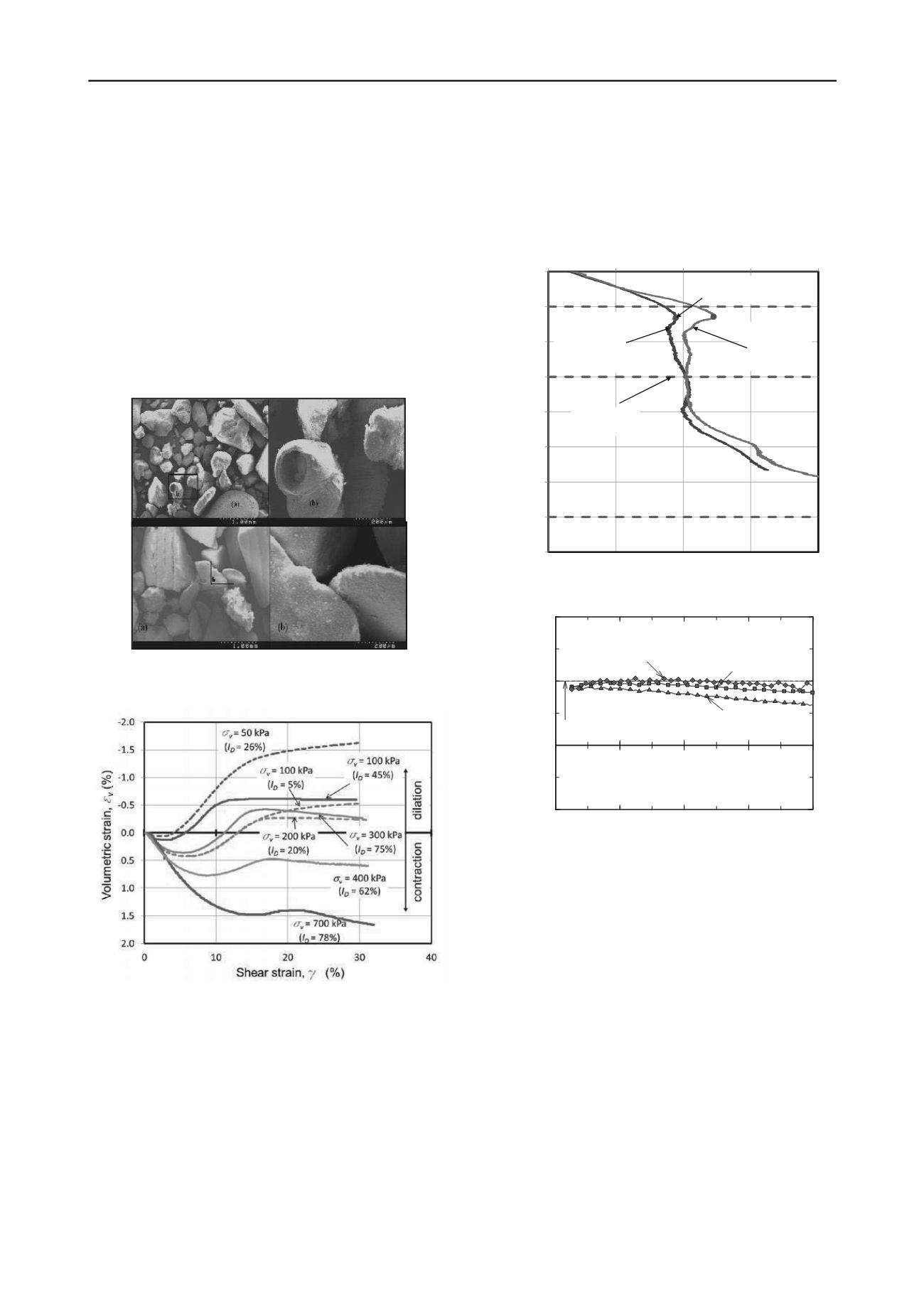

Figure 16. Microscopic images of Hormuz Island sand (top) and

Bushehr Port sand (bottom) from Shahnazari et al. (2013).

Figure 17. Volumetric change of carbonate sand in drained simple shear

test with lateral stress ratio

K

= 0.4 (Safinus et al. (2013).

Observations of the experimental behaviour of two pumice

sands from Japan and New Zealand are made by Kikkawa et al.

(2013). While the composition of Pumice sands is dominated by

silica and aluminium oxide, they are normally characterised by

the presence of particles that are easily crushed against a hard

surface under fingernail pressure. Considerable particle

breakage is occurring in triaxial compression loading, while

mobilization of the drained shear strength is increasing steadily

with the shear strain. However, owing to a different stress path,

less crushing is occurring in undrained testing. A particularly

interesting feature of the drained shear behaviour of these two

materials is that with a sufficiently large confining pressure they

tend to deform in one-dimensional compression way, with

practically no change in the diameter of the sample, also a

consequence of the large amount of particle crushing. An

example of observed incremental strain ratio evolution for one

of the materials during triaxial testing is shown in Figure 19.

0

0.25

0.5

0.75

1

1.25

1.5

1.75

2

0

100

200

300

400

Normalised penetration depth,

d

/

D

Vertical bearing pressure,

q

u

(kPa)

Soft clay

Soft clay

Carbonate

sand

I

D

= 38%;

f

crit

= 40

°

Silica sand

I

D

= 38%;

f

crit

= 34

°

Stiff clay

Punch-

through

Layer

interface

Figure 18. Effect of interbedded sand mineralogy on load penetration

response: severity of punch-through

(Safinus et al. (2013).

Figure 19. Incremental strain ratio against axial strain for drained

triaxial tests on pumice sand from Japan (Kikkawa et al. 2013).

6 CONCLUSION

This paper presents a General Report of 29 written

contributions from authors representing 22 countries submitted

for one of the parallel sessions,

Time effects and other peculiar

observation,

of the Technical Committee 101: Laboratory Stress

Strength Testing of Geomaterials. The General Report reviews

these contributions and presents the current research directions

mainly in relation to the experimental behaviour as well as the

key outcome results. The topics covered by the written

contributions have been grouped within the following thematic

strands:

Time effects: creep, strain rate effects in fine soils;

Consolidation/compressibility (loading and unloading);

Expansive soils: swelling/shrinkage characterisation;

Crushable granular soils.

Various analytical and constitutive modelling approaches

successfully assisted the interpretation of the presented

experimental data and in general, the research methodology

0

2

4

6

8

-1

0

1

2

Strain ratio

d

v

/

d

a

Axial strain

a

(%)

JPN pumice

d

=5.70kN/m

2

100kPa

JPN pumice

d

=5.77kN/m

2

1600kPa

JPN pumice

d

=5.70kN/m

2

400kPa

One dimensional

compression