185

Special Lecture /

Conférences spéciales

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

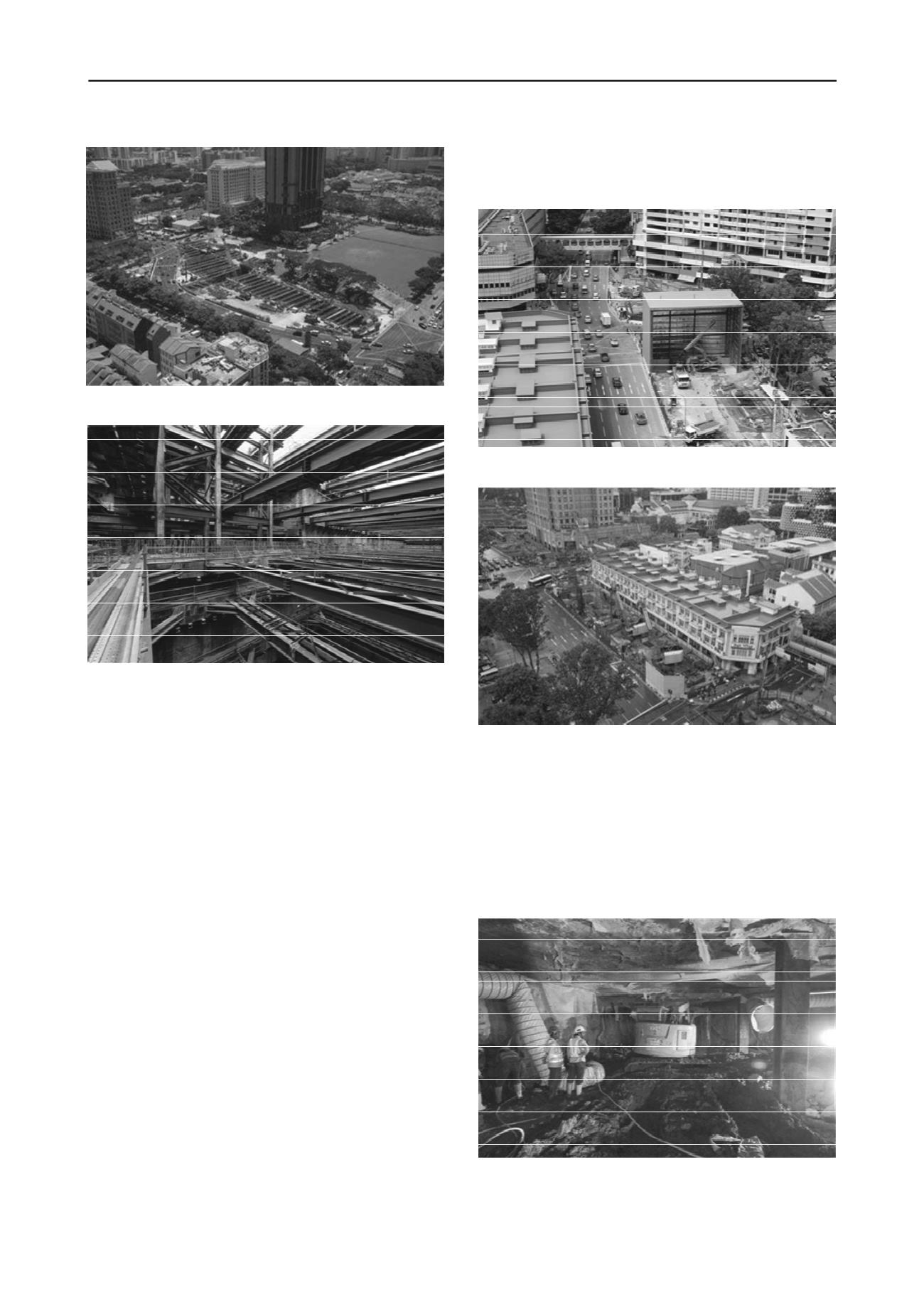

Figure 3. A view of the Station area showing the bottom up excavation

and the Rochor Road diversion around the site.

Figure 4. A picture from inside the Station showing the struting required

for the bottom up excavation.

4 CONSTRUCTION BY TOP DOWN METHOD

The Top Down method was used primarily in areas where it

was essential to reinstate the Rochor Road to maintain traffic

flow along this busy route. In general, the retaining walls, jet

grouting or cross walls and roof slab were done in two phases

by shifting the road alignment slightly to create space to work

on one side of the tunnel at any one time.

The top down sections are South of Beach Road and from

North Bridge Road right to the Northern end of the site after

Queen Street. The corridor for the tunnels at these locations was

very tight and with buildings very close to the alignment of the

tunnels the top down method also afforded a very stiff structure

to be built minimising settlements and therefore potential

damage to the adjacent assets. It was especially the case in the

section in front of the Bugis Village, a row of heritage shop

houses fronting Rochor Road between Victoria Street and

Queen Street.

To facilitate the bulk excavation, ‘off line’ shafts were

constructed at several locations to allow the removal of the

excavated material. Towards the Northern end of the site

adjacent to the Rochor Centre a public housing complex, noise

mitigation measures were required around the shaft prevent

nuisance to the neighbours.

Indeed for much of the diaphragm wall, cross wall and

barrette foundation work, noise mitigation measures were

normal practice. A large acoustic screen was erected at the

beginning of the Contract between the Station site area and a

row of private houses and Soletanche Bachy developed a

special sound proofing around the excavation cranes. Baptised

the ‘Ninja Turtle’, the sound enclosure incorporated cameras to

ensure that the operators vision was not impaired and also a air

conditioning system to prevent overheating of the machines.

This was one of the innovative ideas that were put into practice

on the site which won an award from the Singapore Workplace

Safety & Health Council.

Figure 5. The acoustic enclosure around the top down access shaft

adjacent to the Rochor Centre.

Figure 6. Excavation for the diaphragm walls in front of Bugis Village.

Note the green ‘Ninja Turtle’ enclosure around the two excavation

cranes.

With the walls and roof of the top down section cast and the

road reinstated above, the excavation continued by ‘mining’

below the roof slab and then constructing temporary supports

(generally, reinforced concrete struts) or the definitive

reinforced concrete slabs. Once the overall structure was

complete and waterproofed, the voids between the tunnels and

the surface were backfilled using a self compacting ‘liquid soil’

material.

Figure 7. A view of the excavation in a ‘top down’ section, working

below the roof slab.