184

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

above, the whole line will be underground. More than half a

million commuters are expected daily on this line.

The three stages will have a staggered opening with stage

one (DTL1) to be completed by 2013 followed by DTL2 in

2015 and DTL3 in 2017. Stage One incorporates the stations in

the existing Central Business District through the New

Downtown to the Bugis district and will have four interchange

stations linking into three different underground lines: North

East Line at Chinatown; the East West Line at Bugis; the Circle

Line at Bayfront and Promenade Stations. Construction of this

line started early in 2008.

2.2.

DTL1 C903 Bugis Station and Associated Tunnels

Contract 903, Bugis Station and Associated Tunnels, was

awarded in November 2008 to Soletanche Bachy as main

contractor, and leader of the Joint Venture with local company

Koh Brothers. It was the last contract awarded on DTL1 and is a

Construct Only contract with the design being undertaken by

Arup on behalf of the LTA. At the time, it was the largest rail

project ever awarded by the LTA at S$582 million (360m euros

at current exchange rates). The new Bugis Station will be the

terminus for Stage One of Downtown Line (DTL1) and was

therefore a critical section as the crossover and overrun was

integrated within this contract.

The Bugis area is an important commercial centre,

historically linked to seaborne trading but now a thriving area

with private and public housing, major shopping and

commercial complexes along with a large private hospital.

Bugis is surrounded by the tourist areas of Little India and

Kampong Glam. The new station was to be build partially

below Rochor Road and adjacent open land, whilst the cut and

cover tunnels were built below the heavily traffic Rochor Road.

Indeed Rochor Road is one of two principal arteries into central

Singapore from the South and the first when coming from the

airport via the busy East Coast Parkway.

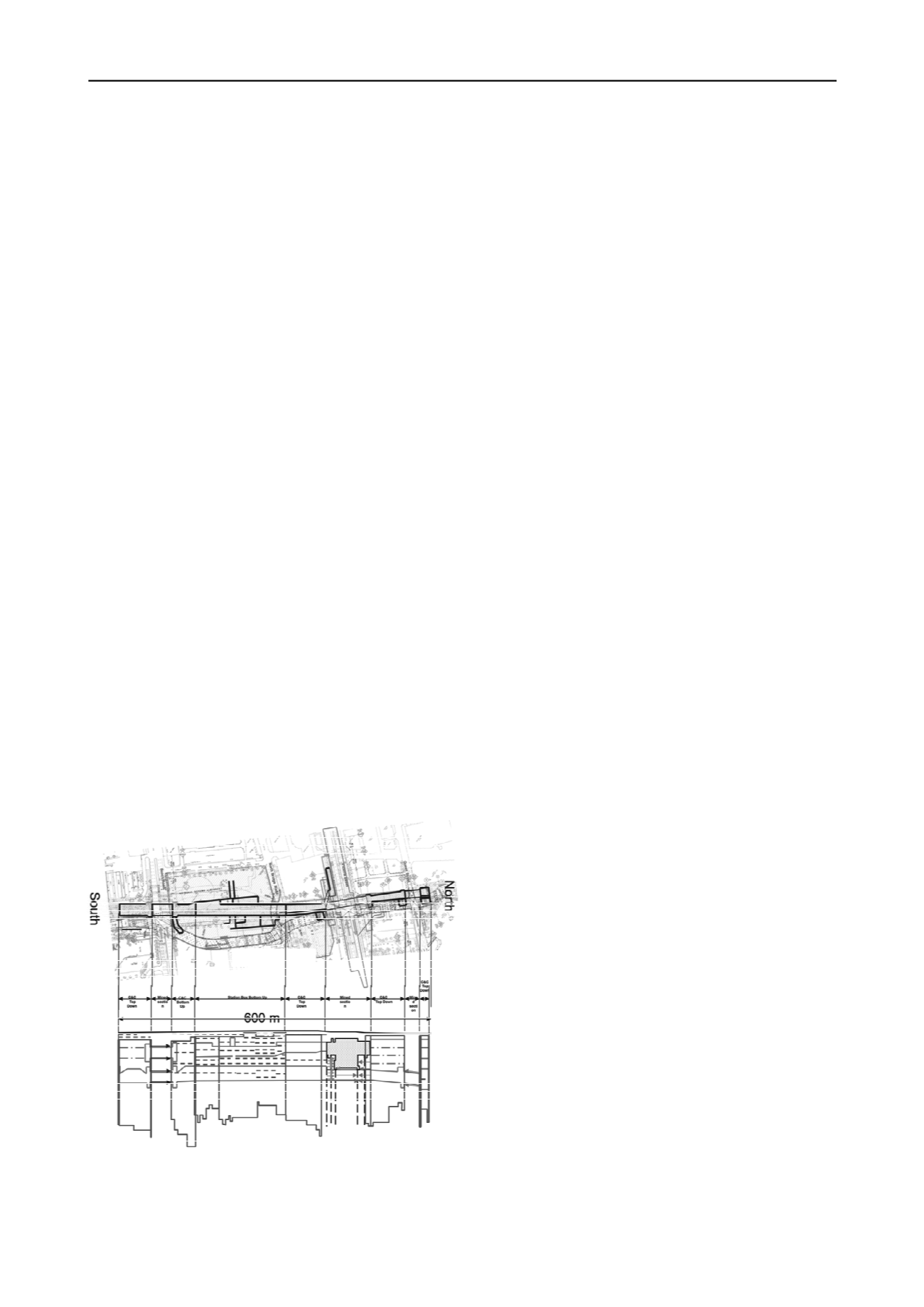

The project extends over 600m with four major road

crossings at Beach Road, North Bridge Road, Victoria Street

and Queen Street. The Victoria Street crossing is further

complicated due to the existing Bugis MRT Station running

below the street and across the alignment of the new tunnels. At

Beach Road and Queen Street numerous utilities ran below the

surface.

Figure 2. Schematic plan and cross section of the overall works.

Due to the number of technical and physical constraints it

was necessary to construct nearly all of this entire section as a

cut and cover. At the Southern end the crossover precluded

bored tunneling and beyond the station the physical constraints

going below the existing Bugis Station and the narrow

horizontal footprint meant a cut and cover tunnel was the only

solution until after Queen Street. Furthermore, the connection

tunnels from the new to the existing station would also mean

significant works below Rochor Road.

At either end of the project, bored tunnels would make the

connection to the adjacent stations. At the Southern end a

temporary access shaft was constructed by the neighbouring

contractor to launch their TBM’s towards Promenade Station

and at the North end a receiving shaft was built to reception the

TBM’s coming from Rochor Station, the first DTL2 station.

The excavation depth for the station and tunnels varies along

the alignment but was generally 27m below ground level with

the deepest section at the Queen Street receiving shaft.

The geology in this area of Singapore is essentially 3 to 5m

of fill/sand overlaying 20 to 30m of Marine Clay above Old

Alluvium.

All the major retaining walls were constructed using the

diaphragm wall technique and barrette piles were used for the

foundations. The excavation depth and the stiffness required to

avoid settlement and movement to the surrounding assets meant

that a robust earth retention system was required over the full

length of the project. Due to the very soft clays overlying the

founding Old Alluvium, additional strengthening of the ground

was required prior to bulk excavation to minimise deflection of

the retaining walls. This was carried out using two different

techniques. In areas where utilities and obstructions were

expected, one or two jet grouted slabs were installed to improve

horizontal restraint. In more open areas such as the station, cross

walls were constructed between the two retaining walls built

using the same equipment as the diaphragm walling. Soletanche

Bachy were able to propose a value engineering scheme where a

significant section of jet grouting was replaced by cross walls.

In addition to being a more robust solution, there was a benefit

to the programme as the same equipment could be used

reducing congestion on the working platforms and as

importantly no additional materials testing regime was required

such as the lengthy coring of the jet grouted slab to ensure

compliance with the specifications.

As explained below a three principal construction methods

were necessary to overcome the environment that the physical

constraints imposed over the length of the site. These were

using the Bottom Up and Top Down Methods for cut and cover

construction and mined tunnels where existing infrastructure

precluded open excavation.

3 CONSTRUCTION BY BOTTOM UP METHOD

The Bottom Up method was applied in the central area of the

site between Beach Road and North Bridge Road. This area had

less physical constraints and the Contractor had the space to

move Rochor Road to either side of the excavation during the

construction.

Once the diaphragm wall was constructed the bulk

excavation could commence. Up to 9 layers of steel struts were

installed to support the retaining walls as the excavation

proceeded to a depth of 27m. A total of 20,000 tonnes of steel

struts were installed for the whole site (nearly three times the

Eiffel Tower’s 7,300 tonnes!). Once the excavation reached the

formation level, the base slab is poured and the structure built

from the bottom back up to the roof slab. As the reinforced

concrete structure is built and the walls braced by the inner

structure, the temporary steel struts can be removed.