17

Terzaghi Oration

/ Allocution Terzaghi

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

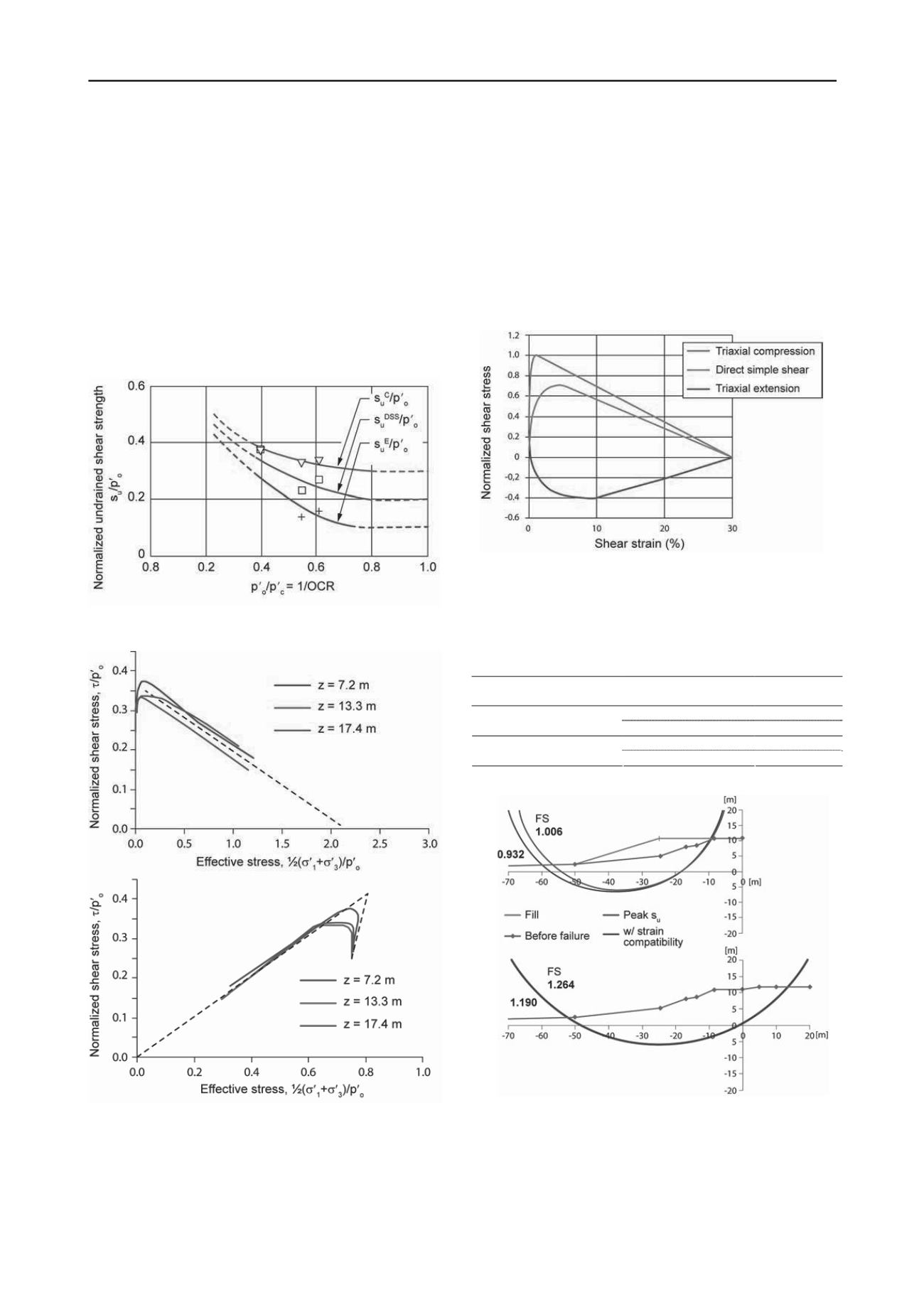

100 below 12 m. The overconsolidation ratio below the drying

crust was 1.1, due to aging) Figure 1 provides profiles of undis-

turbed and remoulded undrained shear strength from the field

vane test (FV). Figure 2 presents the undrained shear strength

normalized with the effective overburden stress, p'

o

, from triax-

ial compression, direct simple shear and triaxial extension tests

vs

the inverse of the overconsolidation ratio (OCR). Specimens

from depths of 7, 13 and 17 m were tested. Figure 3 illustrates

three stress strain curves and effective stress paths from anisot-

ropically consolidated triaxial compression tests. The residual

shear strength and the peak shear strength for a “perfect” sample

are also indicated with the dashed line. To simulate a “perfect”

sample, the effective stress path of a perfect specimen follows

an angle of 1:3 up to the failure line (Berre

et al

2007).

Figure 2. Normalized undrained shear strength, Vestfossen clay (Grim-

stad and Jostad, 2011a).

Figure 3. Stress-strain curves and effective stress paths from triaxial

compression tests, Vestfossen clay (Grimstad and Jostad, 2011b).

4.3

Analyses of the slide

4.3.1

Limit equilibrium analyses

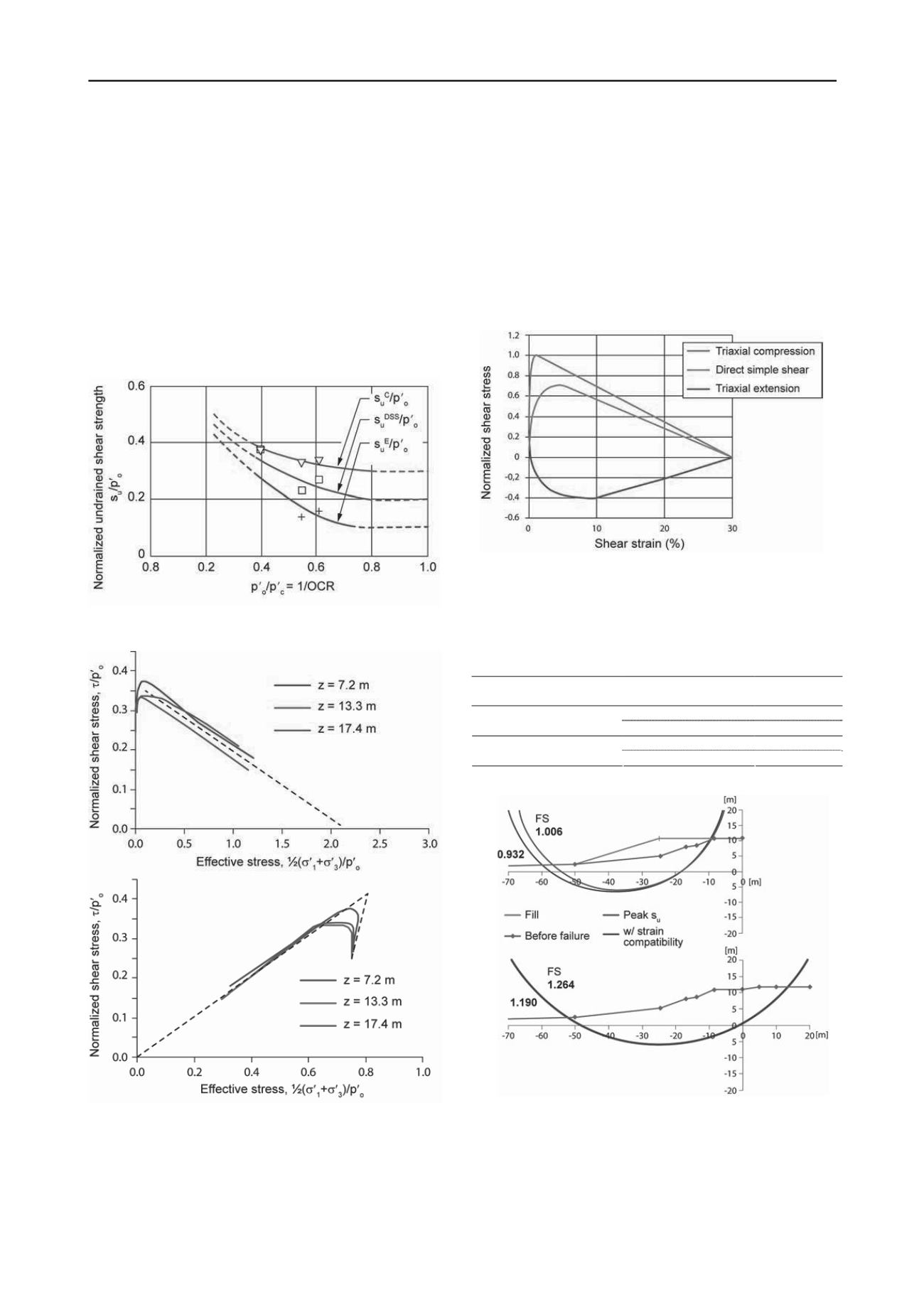

The classic Fellenius method was used, where the factor of

safety, FS, is calculated from the ratio of the sum of resisting to

the sum of driving forces. The calculations considered strain

compatibility (Grimstad and Jostad 2012). The strain compati-

bility was achieved by finding the highest safety factor on a

given slip surface for different constant shear deformations.

Thereafter, the slip surface giving the lowest safety factor was

located. The strain-compatible critical slip surface was not nec-

essarily the same as for the case without strain compatibility.

To do strain-compatible calculations, an idealized material

model was used, as shown in Figure 4. The peak shear stress

was taken at a shear strain of 1% in triaxial compression, 5% in

direct simple shear and 10% in triaxial extension.

Figure 4. Idealized anisotropic stress-strain model for strain-

compatibility modelling (Grimstad and Jostad 2012).

Figure 5 presents the results of the limit equilibrium stability

analyses when the peak undrained shear strengths were used.

The factors of safety obtained are listed in Table 5.

Table 5. Result of limiting equilibrium analyses of Vestfossen slide.

Case

(Slip surface)

Strain compatibility

Factor of

safety

No

1.01

Fill added

(Fig. 5, top)

Yes

0.93

No

1.26

Before addition of fill

(Fig. 5, bottom)

Yes

1.19

Figure 5. Result of limiting equilibrium analyses of Vestfossen slide

(Grimstad and Jostad 2012).

Including the strain compatibility criterion decreased the safety

factor by about 7%. With the strain-compatible model and the

added fill, the slip surface extended further beyond the toe. The

safety factor of 1.2 for the case “before the addition of the fill”