3416

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

(McCartney et al., 2010). Countries such as China, Ireland and

Japan are also experiencing an increased interest in the use of

thermo-active piles (Hamada et al., 2007, Gao et al., 2008,

Hemmingway and Long, 2011, Jalaluddin et al., 2011).

3 ENERGY PILE FIELD TEST

3.1

Background

The study conducted at Monash University is part of an

international research effort aimed at obtaining a much better

understanding of the thermo-mechanical effect on piles with the

view of reducing the conservative approach taken so far in the

design of energy piles. The study involves evaluation of the

thermo-mechanical behaviour of soils, the thermal capacity of

the pile, the built structure heat balance, soil thermal properties

and influence of heat transfer on pile load capacity and shaft

resistance. This paper reports on the pile field test undertaken at

the Clayton campus of Monash University, Victoria, Australia.

3.2

Site temperature profile

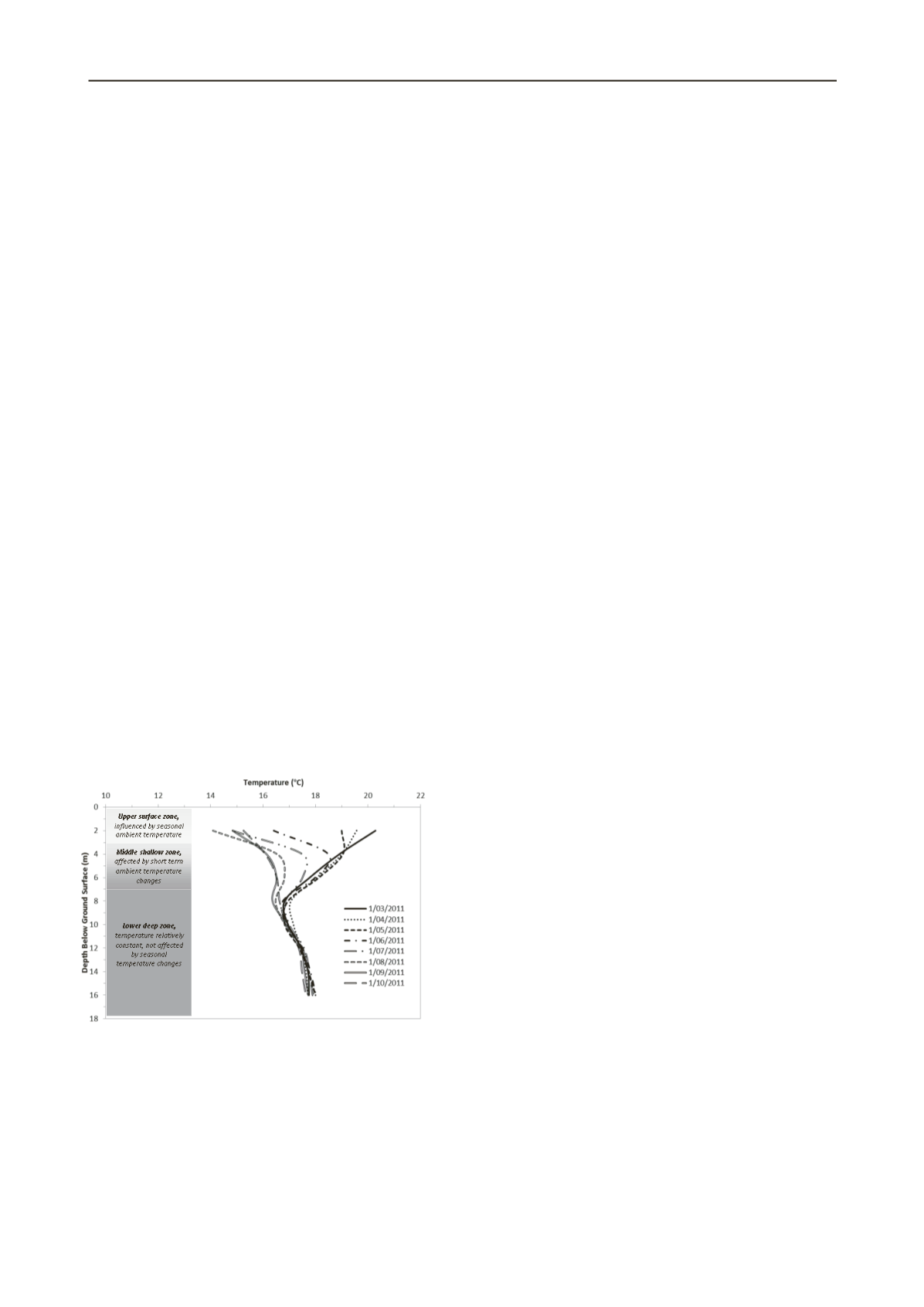

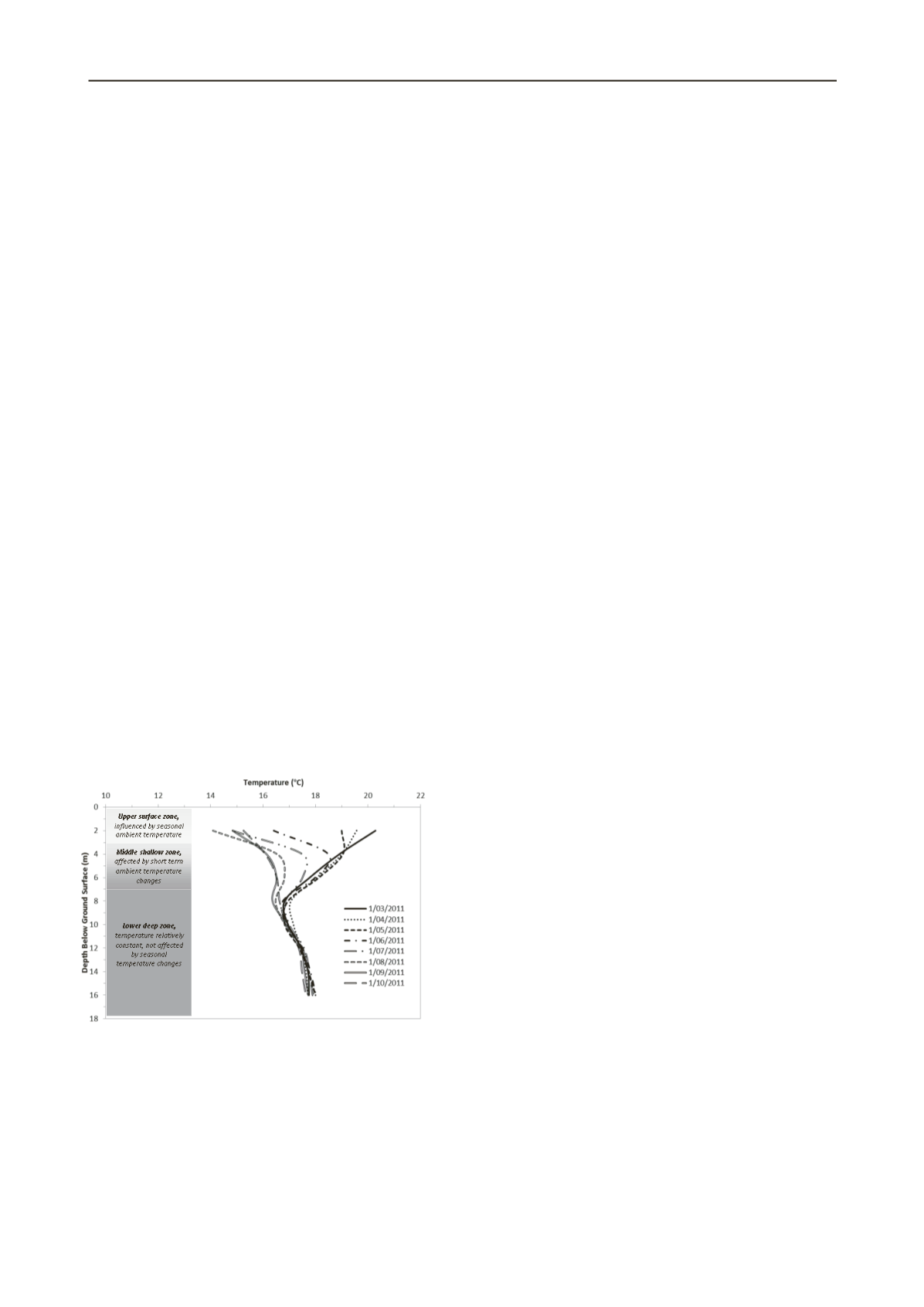

To efficiently operate a heat exchanger pile system, the ground

temperature needs to be warmer than the air temperature in

winter and cooler than the air temperature during summer. This

requires a ground with relatively constant temperature and

knowledge of the magnitude of ground temperature changes for

this system to operate efficiently. In-situ temperature profiling

was conducted at the pile field test site. The site consists of 3 m

thick clayey fill overlying Brighton Group materials from 3 m

onward. The Brighton group consists mostly of fine to coarse

very dense clayey sands and sands. Monitoring of ground

temperature variation (Figure 1) indicates that the temperature

of the surface zone (approximately 2 m below ground surface)

and, to a lesser extent, that of the shallow zone (2 to 6 m) are

influenced by short term ambient temperature changes. These

variations begin to diminish upon reaching a depth greater than

that of the shallow zone. Beyond 8 m (deep zone) temperatures

are relatively constant (17-18 ºC) and are unaffected by seasonal

temperatures changes making them suitable for heat exchanger

pile systems.

Figure 1. Typical ground temperature variation with depth, recorded at

Clayton, Australia.

3.3

Energy pile setup

The Monash field heat exchanger or energy pile was installed in

December 2010. It is a 600 mm diameter bored pile drilled to a

depth of 16.1 m in Brighton Group materials. Groundwater was

not observed during the installation process. Two levels of

Osterberg cells (O-cells) were installed at 10 m and 14.5 m

depth. By using two O-Cell levels, an accurate independent

measurement can be taken for the material within the

intermediate sections of the pile by observing the reaction of the

relevant strain and displacement gauges with or without thermal

loading. The use of O-cell also eliminates health and safety and

other constraints associated with conventional static testing

systems such as kentledge or anchor piles. The testing and

monitoring equipment installed within the pile consisted of the

following:

•

Three loops of HDPE pipe (25 mm OD) attached to the

pile cage, to 14.2 m, to circulate the heating transfer fluid.

•

10 vibrating wire strain gauges installed between the

two O-cells levels and 6 vibrating wire strain gauges installed

above the upper O-cell level.

•

12 vibrating wire displacement transducers installed

within the pile to measure O-cell and pile movements.

•

All vibrating wire instrumentations were fitted with a

thermistor, and temperature of the concrete monitored at various

levels.

Two boreholes were installed at a distance of 0.5 m and

2.0 m to the energy test pile, thermocouples were installed at

2 m intervals in each borehole to profile the temperature

changes with depth and measure ground temperature during

thermal loading.

4 FIELD PILE TEST RESULTS

4.1

Thermal properties

The ground thermal properties are paramount for an accurate

design of a geothermal energy installation especially when it

comes to sizing and costing the system. In this respect, in-situ

ground thermal conductivity, pile thermal resistance and

undisturbed ground temperature are key parameters for a

successful design. The most important parameter required to

optimise the design of energy piles or boreholes ground heat

exchangers is the thermal conductivity of the ground (heat

exchanger system and the surrounding soils). For the

preliminary design of complex energy foundations or the

detailed design of standard geothermal systems, sufficient

accuracy of ground thermal properties can be obtained from

field thermal response or laboratory testing. The thermal

conductivity of the ground, which is directly relevant to the

temperature-depth relationship, is sensitive to the local on-site

geology and affected by its mineralogical composition, density,

pore fluid and degree of saturation (Abuel-Naga et al., 2008,

2009). As a result, there is no constant depth at which all

geothermal energy systems should be installed. Rather, factors

such as local geology, climate and even surface cover must be

considered in order to help determine a depth at which the

ground temperature is relatively unaffected by seasonal

temperature changes and to specify the required length of heat

exchangers needed for the pile foundation.

Some of the thermal property parameters can be determined

in laboratory tests but inclusion of site specific conditions such

as groundwater flow and in-situ stresses are difficult to

implement. Currently there is no testing standard available to

conduct in-situ thermal conductivity of energy piles and assess

their thermal resistance. However, the American Society of

Heating, Refrigeration and Air Conditioning (ASHRAE)

published a set of recommended procedures for undertaking

formation thermal conductivity tests for geothermal applications

(ASHRAE 1118-TRP). This procedure is popular with the

borehole ground loop systems. However, the diameter of a

borehole compared to a pile is a lot smaller and the number of

piping loops is also lower.

Three Thermal Response Tests (TRTs) were carried out

during the heating periods of the field testing program. The

TRTs were carried out utilising a TRT unit consisting of a

computerised logging system, control box, water pump, heating

elements and a water reservoir. There is one outlet and one

inlet on the TRT Unit. One TRT was carried out by circulating