3421

Technical Committee 307 + 212 /

Comité technique 307 + 212

Table 3. Material parameters of rock

Young's modulus

E

(MPa)

9800.0

Poisson's ratio

0.295

Stress ratio at critical

R

CS

(=

1

/

3

)

3.0

Plastic stiffness

E

p

0.002

Potential shape parameter

1.5

Time dependent parameter

1.5

Time dependent parameter

C

n

0.005

Overconsolidation parameter

a

8000

Reference void ratio

e

0

(

m0

=98kPa)

0.159

Table 4. Physical properties of rock

Preconsolidation pressure (MPa)

900

Thermal expansion coefficient

T

(1/K)

8.0×10

-6

Water

(1/K)

2.1×10

-4

Permeability

k

(m/s)

5×10

-12

Thermal conductivity

K

t

(kJ m

-1

K

-1

Min

-1

)

0.18

Specific heat

C

(kJ Mg

-1

K

-1

)

840

Heat transfer coefficient of air boundary

c

((kJ m

-2

K

-

1

Min

-1

)

230

Specific heat of water

C

water

(kJ Mg

-1

K

-1

)

4184

5

10

15

20

-1 -0.5 0 0.5 1 1.5 2

Model

Model

Experiment

Experiment

• • • • • • • • • • • • • • • • •

• •

• •

•• • • • •

• •

• •

•• • • • •

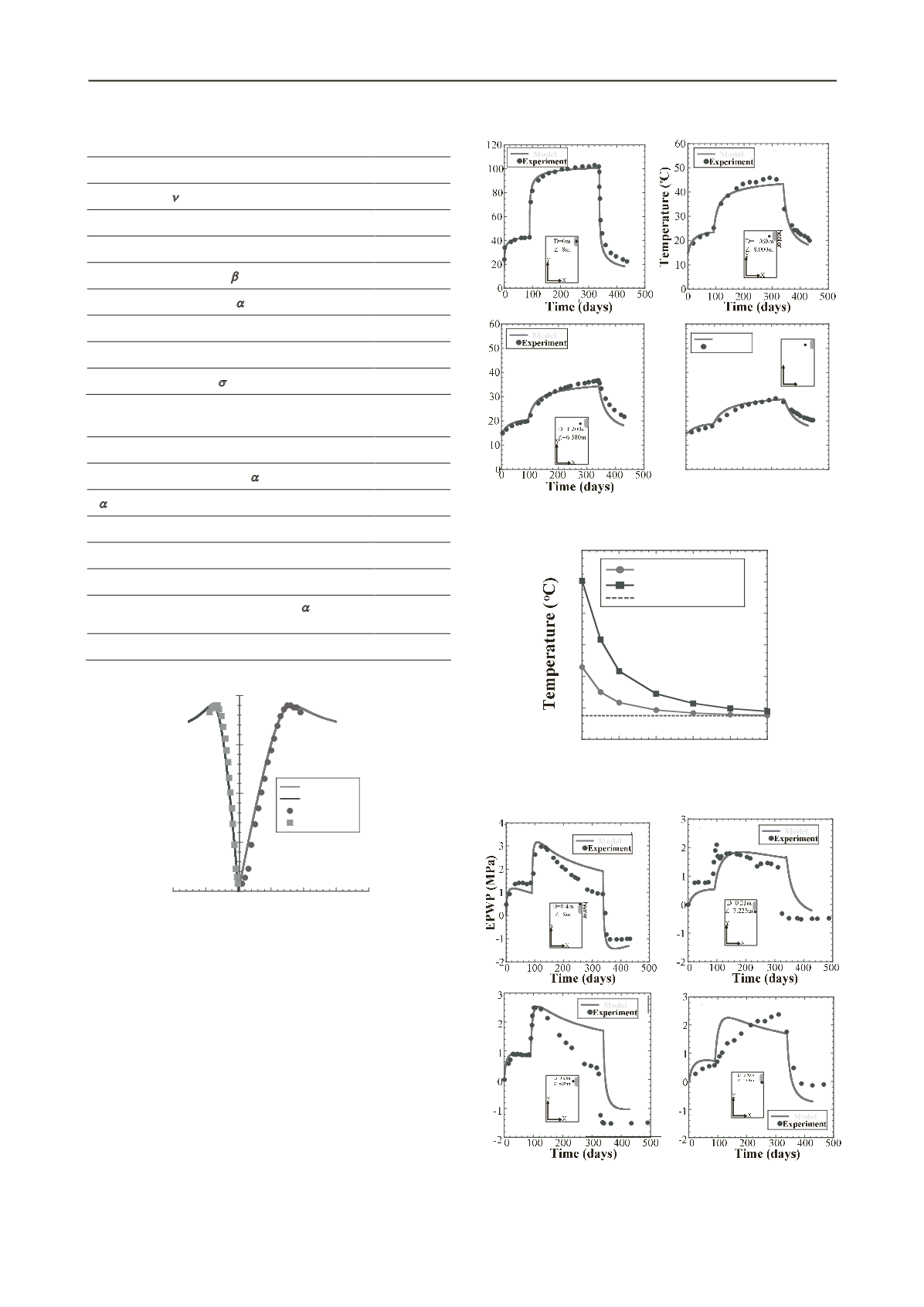

Figure 5. Simulation of triaxial test under confining pressure of 8 MPa

for Opalinus clay

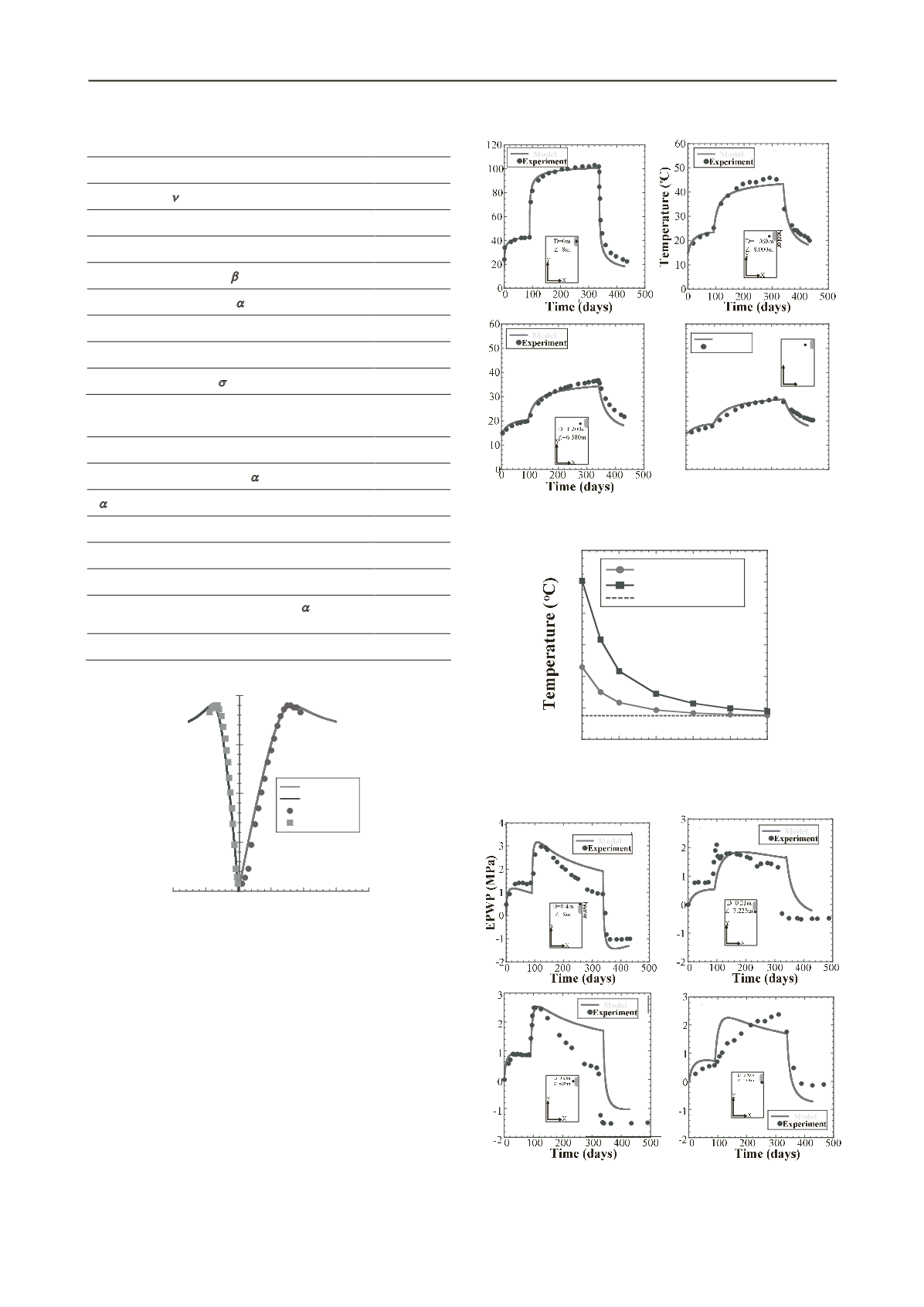

Figure 6 shows the change of temperature at the center of

heater. The temperature reached about 40° at first heating phase,

and then increased very sharply at the second heating phase up

to the highest temperature of about 100°. When the power of

heater is switched off, the temperature decreased sharply. It also

can be seen that the calculated result can well describe the

experimental data. Figure 6 also shows the change of

temperatures at different position. On the whole, the THM-FEM

analysis can well describe the HE-D experiment.

Figure 7 shows the change of temperature at different

positions. It is known from the figure that the nearer the

distance from heater is, the higher temperature will be. There is

no prominent increase of temperature at the distance 5m far

away from the heater due to the small heat conductivity of the

rock.

heater

﴿

heater

heater

X

Y

D=2.200m

Z=5.040m

0

10

20

30

40

50

60

Temperature (

o

C)

0 100 200 300 400 500

Time (days)

Figure 6. Change of temperature at different position

0

20

40

60

80

100

120

0 1 2 3 4 5

Figure 7. Computed temperature distributions at various times on cross

section

heater

heater

heater

PWP

﴾

MPa

﴿

Figure 8. Variation of EPWP at different position

The evolution of EPWP with time is depicted in Figure 8 at

the different sites. It is found that the EPWP increases sharply