3428

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

changes from yellowish brown to reddish brown. This is due to

the oxidation of soil iron content from goethite to maghemite or

hematite (Goforth et al., 2005; Ketterings and Bigham, 2000).

Decomposition of soil particles, especially clay minerals, starts

at temperatures above 550°C (Certini, 2005). These

temperatures are rarely reported for wild and forest fire, but

temperatures up to 1200°C can be achieved during smouldering

remediation (Pironi et al., 2009; Switzer et al., 2009).

This study aims to characterise the effects of moderate and

high temperatures as well as smouldering on soil properties to

determine the impact changes will have to the soil and predict

possible complications that may arise during or after

remediation treatment. Silica sand and kaolin clay are used as

constituents of a synthesised simple soil. Clean untreated, heat-

treated and contaminated/smouldered materials are evaluated to

determine the impacts of the treatment conditions on soil

properties.

2. MATERIALS AND METHODS

Coarse silica sand (Leighton Buzzard 8/16, Sibelco, Sandbach,

UK) and kaolin clay (Whitchem Ltd, UK) were used as the base

soil for all of the experiments. The sand contains 99% silicon-

dioxide, has a mean grain size of 1.34 and a bulk density of

1.7g/cm

3

(Switzer et al., 2009). The sand and clay were

accepted as received and the sand was subjected to the same

pre-treatment. A programmable muffle furnace (Nabertherm

L9/11/SKM, Nabertherm GmbH, Lilienthal, Germany) was

used for all heating experiments. The sands evaluated after

smouldering remediation were prepared in a 3m

3

experiment

involving coal tar mixed with coarse sand. The initial

concentration of this mixture was 31000 ± 14000 mg/kg total

extractable petroleum hydrocarbons before treatment and the

average concentration after smouldering remediation across the

majority of the vessel was 10 ± 4 mg/kg (Pironi et al., 2009).

Table 1. Heat treatment programs

2.1 Sample Preparation and Heat Treatment

The silica sand was washed and wet sieved using a 425µm

screen to eliminate any loose fines and air dried for several

days. In case of mixed samples the dried silica sand was mixed

with 10% mass kaolin clay and 5% moisture content before

being heat treated. For each test, the required amount of samples

was heated in the furnace following the heat treatment

programmes listed in Table 1. After the required exposure

duration, the samples were removed from the muffle furnace

and placed in a desiccator to cool. Samples heated to

temperatures above 500°C were allowed to cool in the furnace

to 200°C before transfer to the desiccator.

2.2 Laboratory Testing

Particle density was measured using the gas-jar method suitable

for coarse soils. Minimum density was measured using 1000g

of sand in a 1L glass measuring cylinder with 20mL graduation

BS1377-2:1990 and BS1377-4:1990). Maximum density was

determined using the vibrating hammer method (BS1377-

4:199). Particle size distribution for the sand was determined

using a sieving method (BS1377-2:1990) using 1.18mm,

600µm, 425µm, 300µm and 212µm sieve sizes. The Atterberg

Limits for the clay were determined using the cone penetration

and rolling methods as outlined in BS1377-2:1990.

The sand-clay mixtures were prepared by dry-mixing 90%

sand and 10% clay (by mass) and then adding distilled water to

achieve a 5% moisture content. The sample was then thoroughly

kneaded in a plastic bag by hand for 10 minutes and allowed to

rest for 2 hours before any heat treatment.

3. RESULTS AND DISCUSSION

3.1. Mineralogy

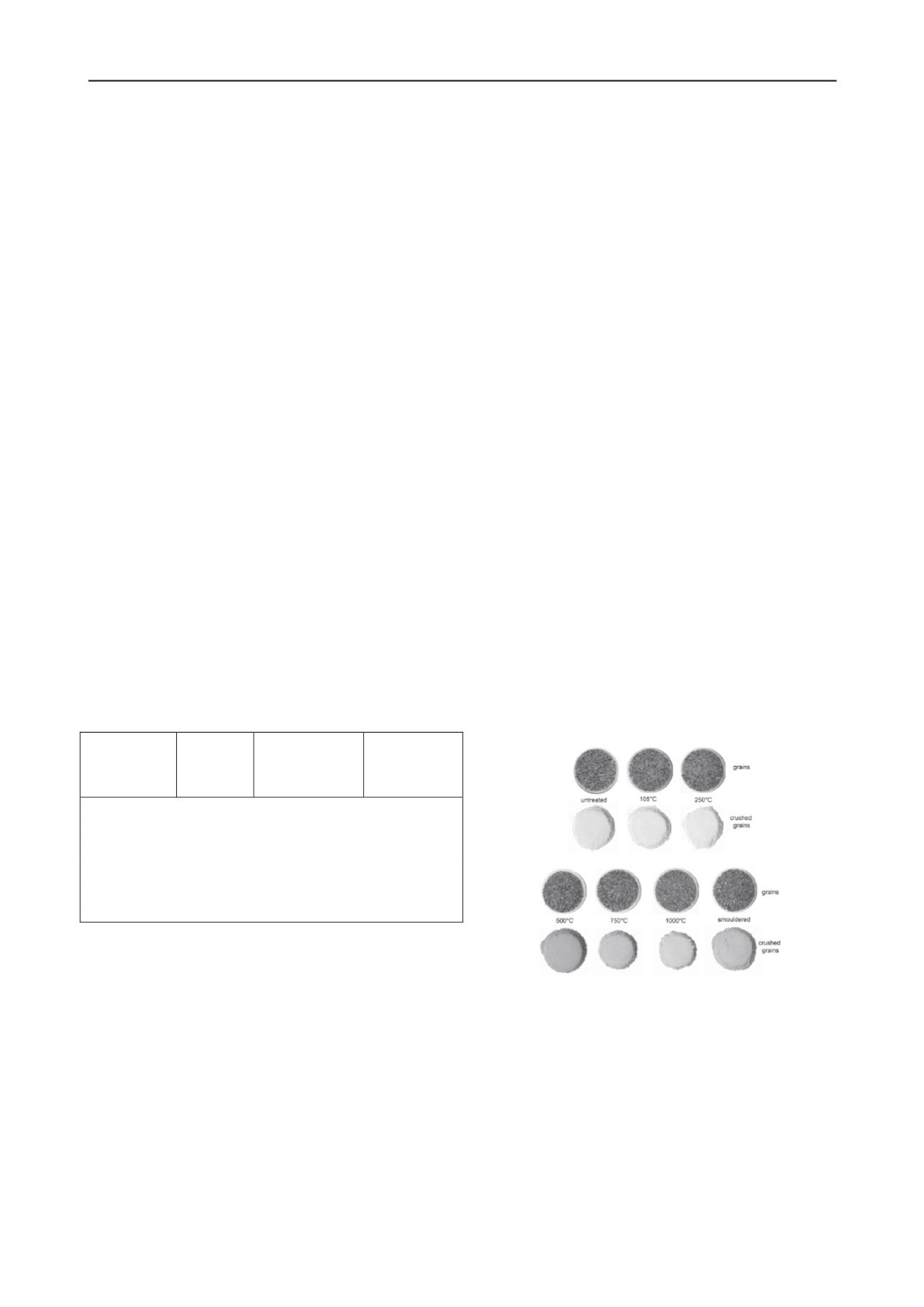

During the heat treatment testing and after smouldering

remediation, a colour change of the silica sand was observed

(Figure 1). Exposure of this material to high temperatures

results in colour change from yellowish brown to reddish brown

with increasing temperature for the silica sand grains and a

change from yellow to pinkish red for the crushed silica sand.

This colour change is associated with the dehydration reaction

of goethite with increasing temperatures to form hematite or

maghemite. During the dehydration, the density of the iron-

hydroxide increases from 4.3 mg/m

3

for goethite to 5.2 mg/m

3

for hematite (Wenk and Bulakh, 2004). The sand is comprised

primarily of silicon dioxide; iron oxides make up a small

fraction of its composition. High temperatures may cause

additional changes in mineralogy that may be less likely to be

detected by visual examination (Goforth et al., 2005; Pomiès et

al., 1998). For example, silicon dioxide becomes unstable with

high temperatures and forms silica polymorphs such as

trydimite or cristobalite (Hand et al., 1998; Wenk and Bulakh,

2004). Thermal treatments (100-1200°C) on fly ash have

transformed quartz minerals to cristobalite and smaller particles

exhibit a characteristic glassy composition due their faster

cooling time (Mollah et al., 1999).

Figure 1. Silica Sand grains and crushed grains after heat treatment.

Sample

Name

Pre-

heating

time

(min)

Peak

temperature

for 60min

cooling

down time

(min)

Untreated

105

30

105°C (24h)

0

250

30

250°C

0

500

30

500°C

~ 60

750

60

750°C

~ 180

1000

60

1000°C

~ 240