3425

Technical Committee 307 + 212 /

Comité technique 307 + 212

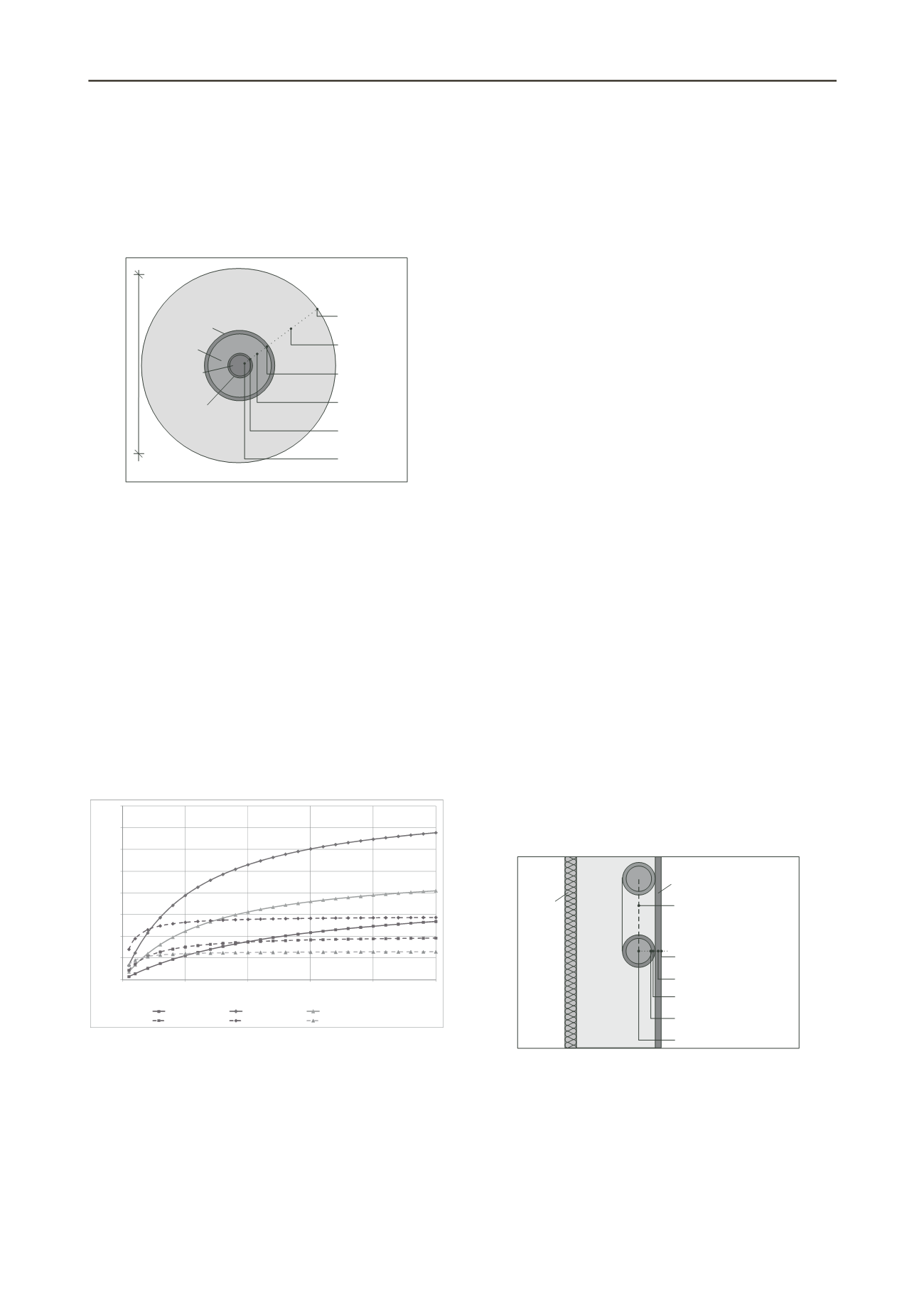

backfill material (s. Figure 3). The main heat transport

mechanisms are conduction (in the backfill material as well as

in the inner and outer pipe) and convection (in the fluid). The

conduction depends mainly on the material properties

(characterized by the thermal conductivity) whereas the

convection depends on the flow rate and the properties of the

fluid (especially viscosity and density).

Backfill

(Sand)

Inflow

Return Flow

276 mm

Convection

(Fluid)

Heat Conduction

(Inner Pipe)

Convection

(Fluid)

Heat Conduction

(Outer Pipe)

Heat Conduction

(Backfill)

Heat Transfer

Dump/Backfill

Dump Material

Outer Pipe

(DN 100)

Inner Pipe

(DN 50)

Figure 3. Heat transfer processes for the coaxial probe installed in the

smouldering dump.

Every existing transport mechanism can be described with

the help of thermal resistances. The different resistances can be

combined with a series connection to a total connection and a

total thermal resistance respectively. Details for the coaxial

probe can be found in Mottaghy and Dijkshoorn (2012).

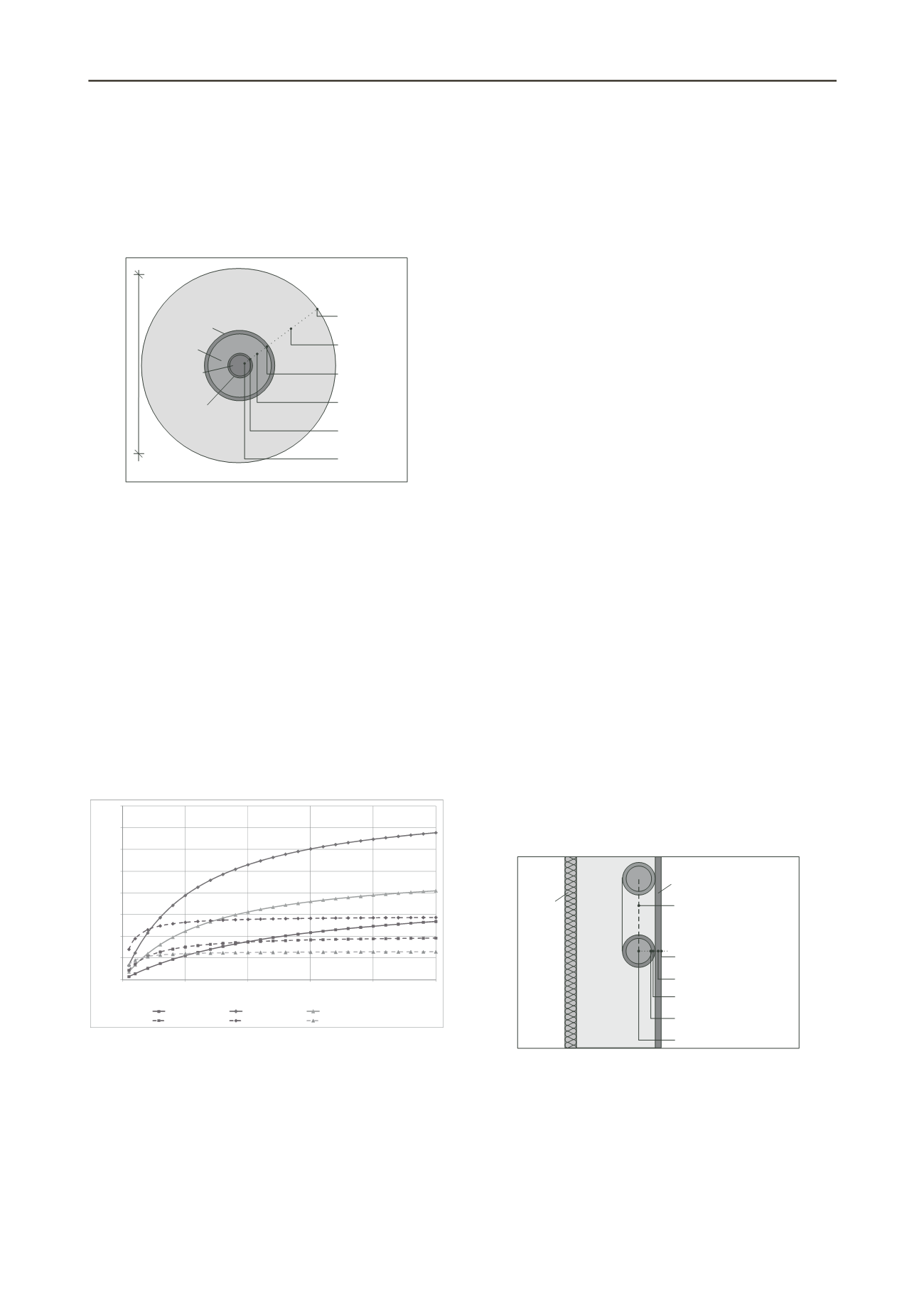

Post-test calculations of the in situ tests were performed to

calibrate the applied model. After that, several analyses were

carried out to identify the most important parameters for the

geothermal utilization of a smouldering. As an example the

influence of the thermal conductivity of the dump and the

backfill material for each BHE is shown in Figure 4. The

differences between the BHEs are caused by the different

temperature regimes in the heat exchanging fields (see Figure

1). It can be seen that the thermal conductivity of the dump

material is the most important parameter. In contrast, increasing

the thermal conductivity of the backfill material has a less

important influence.

0

100

200

300

400

500

600

700

800

0

1

2

3

4

Heatoutput[kW/m]

ThermalConductivity[W/mK]

5

BHE1 (dumpmaterial)

BHE2 (dumpmaterial)

BHE3 (dumpmaterial)

BHE1 (backfillmaterial)

BHE2 (backfillmaterial)

BHE3 (backfillmaterial)

Figure 4. Influence of the thermal conductivity (dump and backfill

material) for the heat output

The thermal conductivity of the existing dump material was

determined in the laboratory. As a result, a value of 0.4 W/(mK)

can be assumed. As expected the thermal conductivity of the

material is very low. Additional, Thermal Response Tests

(TRT) were carried out for each BHE. The resulting effective

thermal conductivities varied between 1.0 W/(mK) (field 3) and

2.2 W/(mK) (Kürten et al. 2009). The effective thermal

conductivity obtained by the TRTs cannot be equated with the

thermal conductivity as a material property. It is rather a

combination of all thermal processes involved. For the

geothermal utilization of a smouldering the high underground

temperature and the thermal radiation must be taken into

account. For transferring the results to another site, the

determining of the correct effective thermal conductivity will be

the main problem.

In summary, the heat transfer inside the dump (heat

replenishment) is the limiting factor the geothermal utilization

of a smouldering. This is the reason why the achieved heat

output of the pilot plant is relatively low comparing to the high

temperatures inside the dump. Nevertheless, by the presented

research project it could be shown that geothermal utilization of

smouldering mining dumps is possible.

4.3

Heat transfer models for plane structure

For symmetric systems such as a BHE several approaches for

the calculation of the heat transfer between ground and soil with

the help of thermal resistances exist. In contrast, for plane

structures there are no equivalent approaches documented. This

may be due to the fact that the occurring processes are more

complex due to the missing rotation-symmetry.

The developed thermo-active seal panels are characterized

by a plane heat transfer. Nevertheless, in dependency of the

boundary conditions the possible heat output of the systems

must be describes realistically for an effective plant design. For

this, a calculation model, which will be also implemented in the

software program SHEMAT, has been developed by the Chair

of Geotechnical Engineering at RWTH Aachen University.

The basic principle of the new calculation model

corresponds to the existing model for a BHE (see section 4.2).

The processes inside the thermo-active structure will be

summarized to a total thermal resistance. The coupling between

SHEMAT and the calculation model will be realized by passing

over temperature boundary conditions and heat flows.

For the development of the calculation model two main

aspects have to be considered. On the one hand, the heat

transfer isn’t symmetric. The heat transfer from the ground to

the heat exchanging system should be the priority flow. Heat

flows from the room have to be minimized to avoid a thermal

circuit. On the other hand, the inflow and the return flow of the

heat exchanging pipes are spatially separated. This means, that

for a numerical simulation the heat exchanging systems cannot

be design as a 1D-dimensional line-element only but rather as a

2D-dimensional element.

For determining the total thermal resistance for a plane

structure the involved processes must be separated. The decisive

single processes are shown in Figure 5.

Heat Transfer

(Soil - Sealing)

Heat Conduction (Sealing)

Heat Conduction (Pipe)

Heat Transfer

(Pipe - Fluid)

Heat Convection (Fluid)

T

In

T

Out

Heat transfer (fluid)

Soil

Concrete

Room

Sealing

Insulation

Figure 5. Heat transfer for a plane structure - thermal processes involved

The single processes can be transferred to a thermal

resistance model (see Figure 6). It can be seen that there are

three determining heat flows: heat flow due to the temperature

difference between the two sides of the wall and the heat flow

due the temperature difference between heat exchanger and

ground and the room respectively. According to the

superposition principle the two heat flows can be overlapped.

The existing triangle mesh of the thermal resistances can be

simplified to a star-network (see Figure 7).