3123

Technical Committee 301 /

Comité technique 301

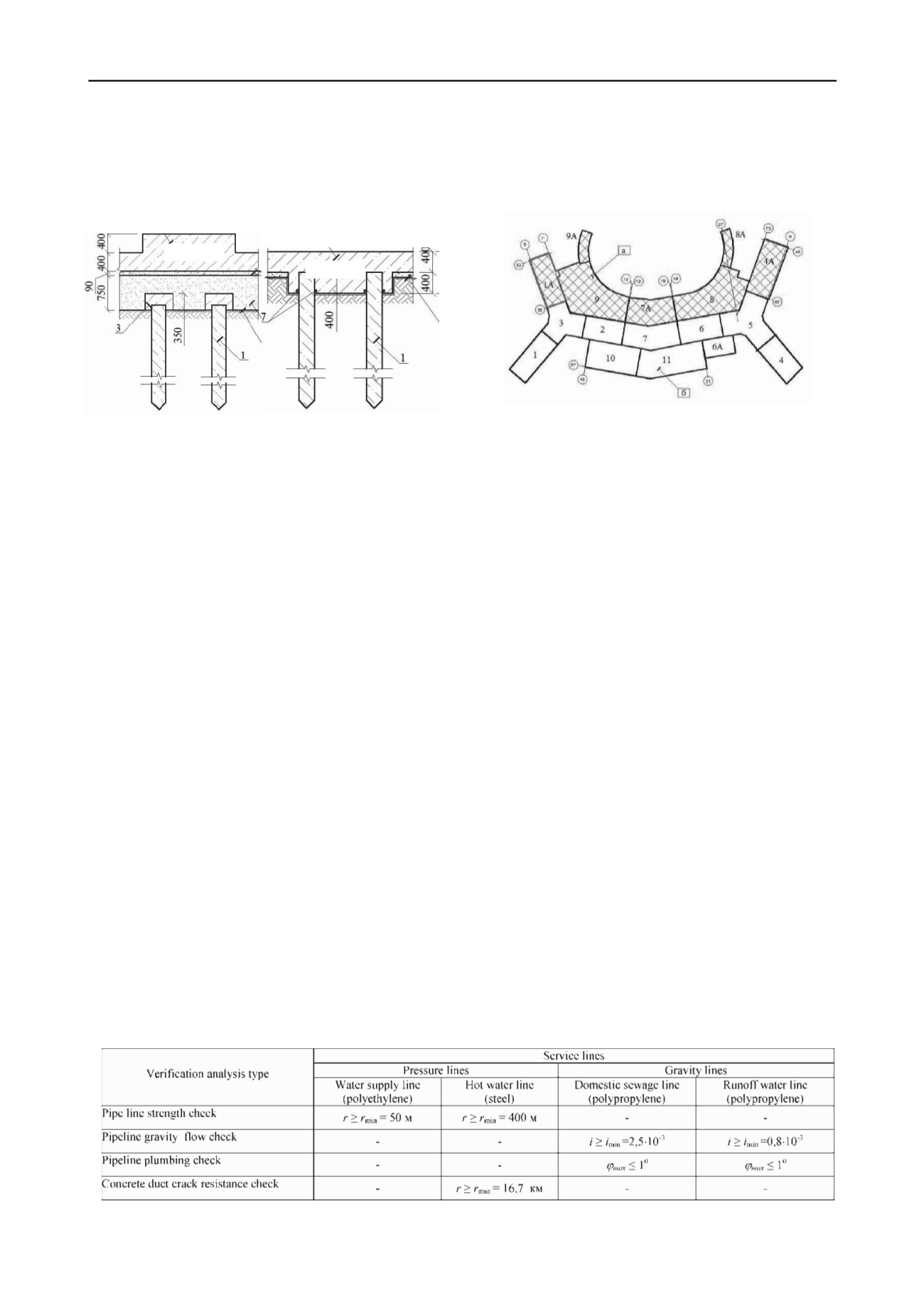

Driven concrete 30x30 cm 4-12 m long piles are applied.

The length of piles depends on the depth of the bearing gravel

and pebble layer, in which the pile tips are at least 0.5 m deep.

Due to variations of geological conditions within the

construction site two types of footings were used in the project

design (fig. 10)

Figure 10. Foundation types for plot 17.

Type 1 (Fig. 10, left) is a concrete raft 400 mm thick with

greater, up to 800 mm thickness, under bearing structures with

flat bottom on pile foundation with intermediate sand and

gravel layer. Presence of this layer practically excludes lateral

seismic load transfer. The intermediate 0.75 m thick layer,

consisting of local sand and sand-gravel soils, compacted layer

by layer, is a damper, it is filled over pile heads having

concrete caps. A layer of geotextile is placed between piles and

under their caps separated from piles by shockproof polystyrol

layer.

Type 2 (Fig. 10, right) is applied for the buildings, sitting on

soil base, containing peats and peaty soils, having Young

modulus of 5…6 МPа. Here a solid raft is designed of variable

thickness, leveled on top, with pile heads fixed in the raft. The

piles, bearing lateral seismic loads, have strong reinforcement in

accordance with construction codes.

The pile field is designed to withstand the main and the

special (seismic) combination of loads.. The design load,

applied to the piles, is 750 kN for the main combination and

1000 kN for the special one. The piles bearing capacity of 1000

kN was proved by static load tests. The design lateral load on

the piles does not exceed 35 kN for pile-raft rigid fixation.

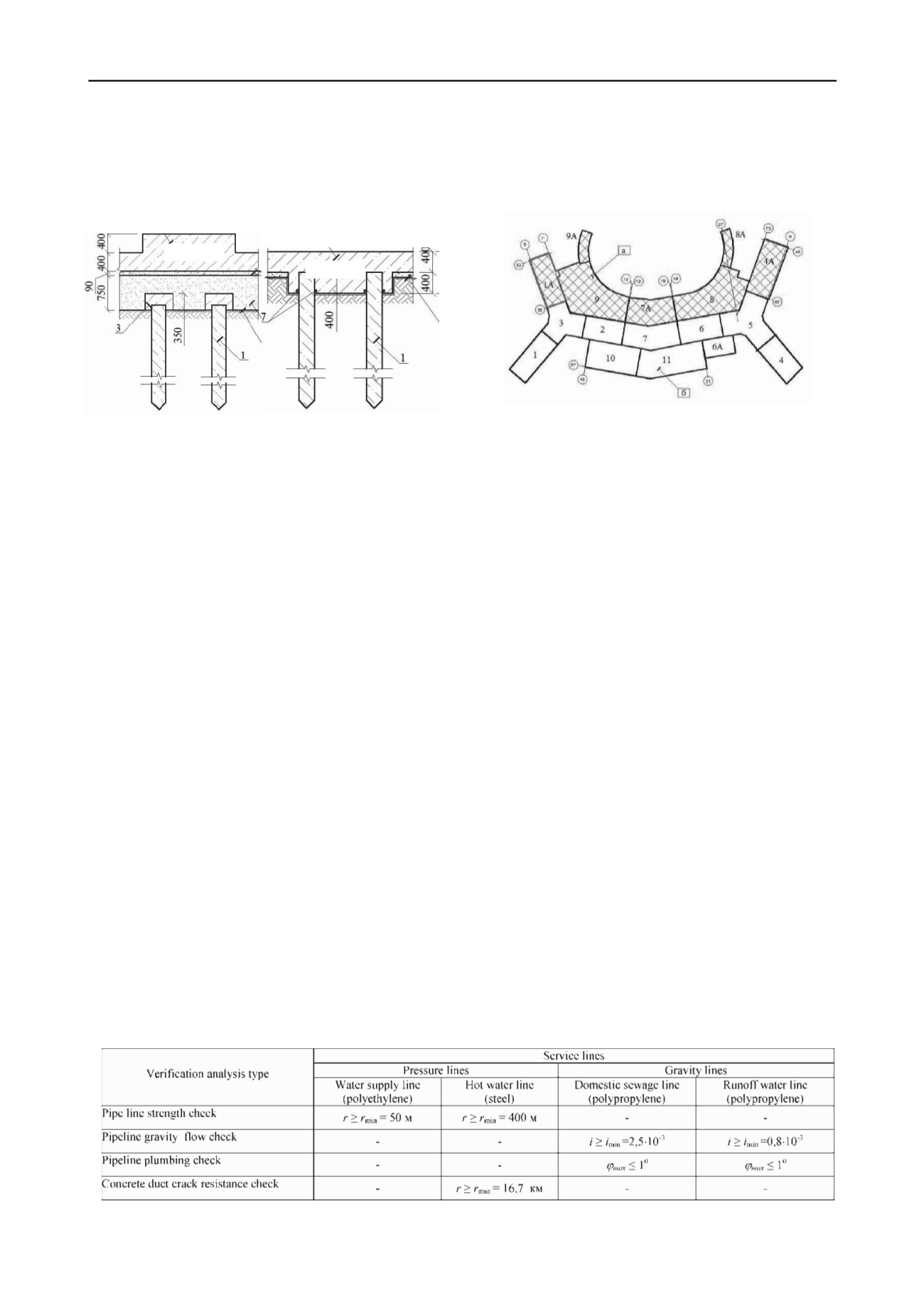

Hotel, apartments and support services at plot D1 are located

in the single building, separated by settlement and anti-seismic

joints into sections (Fig. 11). Overall dimensions of the building

are 150x264m.

Soil conditions of the plot D1 vary significantly within the

building footprint, which determined the choice of different

types of foundations within the same building.

On the part of the site (blocks 1-7, 10, 11 on figure 11),

located close to the shore, surface part of the geologic section

consists of large thick deposits of sand and gravel, underlain by

gravel-pebble soils. For these conditions, the foundation is

designed as a cast reinforced concrete raft with thickness of 400

mm. Under heavily loaded walls and columns 800 mm thick

upward ribs are provided to increase stiffness of raft.

A further from the shore (Blocks 1A, 4A, 7A, 8, 8A and 9 in

Figure 11) upper part of geological section consist of weak

man-made soil, covered by fill produced during engineering

preparation of the construction site. Due to low strength of these

soils, they can not be used as the foundation base. Therefore, to

minimize the differential settlements of adjoining blocks, pile

foundation with intermediate cohesionless soil cushion were

designed similar to the one designed at plot 17 (Fig. 10 left).

F

igure 11. Foundation layout for building on site D1. Hatched areas

represent pile foundation, blank areas – raft foundation.

5

GEOTECHNICAL FEATURES OF UNDERGROUND

PIPELINES DESIGN.

In order to ensure operation of the main Olympic facilities

on Imeretin lowland terrain it was necessary to build a multi-

kilometer long and dense network of various underground

service lines for various purposes (heat and water lines, sewage

and rainwater systems), of various liquid transportation

principles (non-pressurized and pressurized), made of various

pipeline materials (steel, polyethelyne, polypropelene), of

various pipe diameters (250…1580 mm), with and without

protection.

The main issue in foundation design for service lines is the

account of potential considerable differential settlements of soft

consolidating soils and, as a consequence, those of pipelines,

caused by fill loading of the terrain. According calculation

results the settlements of 5…20 m thick soft soils could be up to

0.7 m and could develop for several months or years even if

special geotechnical techniques are applied to accelerate soil

consolidation (sand and geosynthetic drains, temporary loading

fill, jet stabilization, etc.). Application of other techniques of

soil stabilization (stone columns, soil reinforcement, jet

stabilization, etc.) was neither possible for financial and tight

schedule reasons.

In view of the project of such scale the NIIOSP specialists

had to develop special recommendations for service lines that

outlined admissible deformations, missing in Russian

construction codes (see Table 2). The assumed approach was

based on limit state design analyses. This enabled selection of

effective foundations types for the whole spectrum of numerous

waterlines. Thereafter (Fig. 13) some service lines were

designed to sit on driven concrete piles, other ones on cast

concrete strip footing on natural or on improved ground, made

by complete or partial replacement of soft laguna deposits by

Type 1

Type 2

Table 2. Ultimate admissable deformations of service lines.

Note.

r

and

r

min

are design and minimally admissible radius of pipeline curvature;

i

and

i

min

are design and minimally admissible pipeline

slopes;

φ

and

φ

max

are design and maximally allowable angle of rotation in pipeline joints.