2673

Technical Committee 212 /

Comité technique 212

compatibility. The load was applied as pressure in small

increments till the load on the raft equal to the final test load.

Figure 3 shows the quarter model including finite element

meshing adopted in the analysis.

6. LOAD-SETTLEMENT BEHAVIOUR

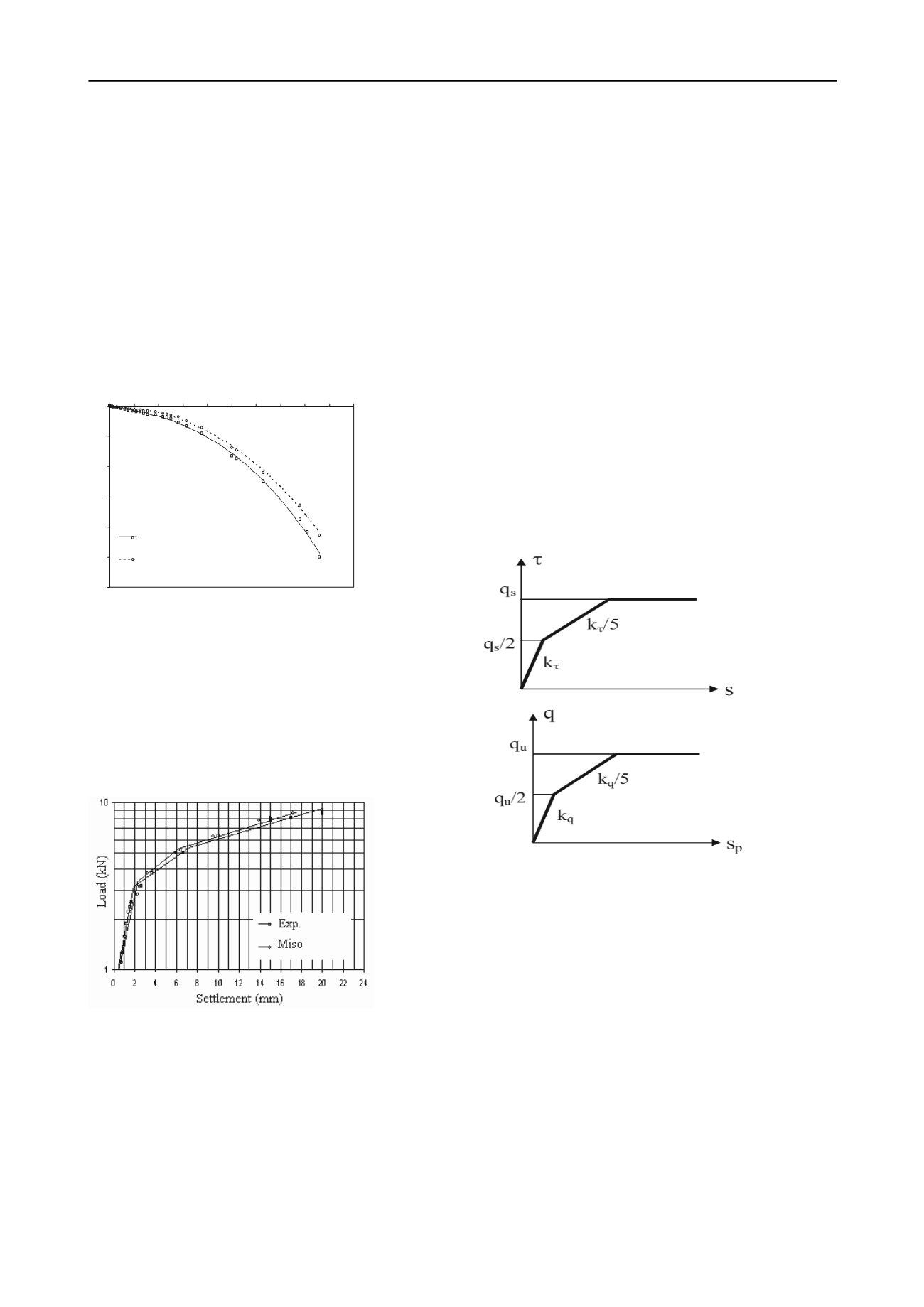

Figure 4 presents the load settlement curves of circular piled raft

obtained from 1g model test and the numerical model. Figure 5

presents comparison of characteristic load-settlement response

of circular piled raft between experiment and numerical

analysis. The results obtained from the 1g model test and

numerical model agree very closely, till the settlement level of

4 mm.

0

4

8

12

16

20

24

0

1 2

3 4

5 6

7 8

9 10

LOAD, kN

SETTLEMENT, m m

EXPERIMENTAL

NUMERICAL - MISO

Figure 4. Comparison of Load-settlement

Figure 5. Characterisation Curves of Experimental and

Numerical Analysis

Figure 6. Tri-linear Model, Frank et al (1991)

As the load increases, the difference in the settlement

between the 1 g model and the numerical model results

increased marginally. However the maximum variation in the

load between the numerical model and the small scale model

results was less than of 5%. This comparison indicates a close

agreement between the numerical model and 1g model test.

Similar observation is made in the analyses of piled raft in loose

and dense sand. Thus the nonlinear analysis using MISO model

idealization for the soil predicts the performance of piled raft

reasonably well.

Although it has been established that the characterised load

settlement response predicted by analytical study and the 1g

model tests have agreed very closely, the basic parameter

namely the Es value of the soil was obtained from the direct

shear tests and the standard correlations available from the

literature The agreement in the results of 1g model and the

numerical analyses can be attributed to the fact that the

supporting medium was prepared under laboratory conditions.

However in the case of field samples the accuracy of the

parameters obtained largely depends upon the sampling

efficiency and the care taken in the extrusion of the specimen

and the preparation of test conditions. The probability of wide

variation while correlating the field data with the laboratory test

results cannot be ruled out. Therefore the evaluation of

parameters from the in-situ tests gain considerable

importance.A well tried procedure for predicting the shaft

friction development has been published by Roger Frank et al.,

(1991) using pressuremeter is discussed below.

7. PREDICTION OF PILE BEHAVIOUR.

PRESSSUREMETER AND ITS APPLICABILITY

The pressuremeter is an effective tool that has been extensively

used to obtain the in-situ parameters and for the last three

decades foundations have been designed based on the

parameters obtained from the in-situ tests. The large volume of

data collected over a period of time particularly the French

Highway authorities has enhanced the confidence level of the

designers in using them for the design of deep foundations.

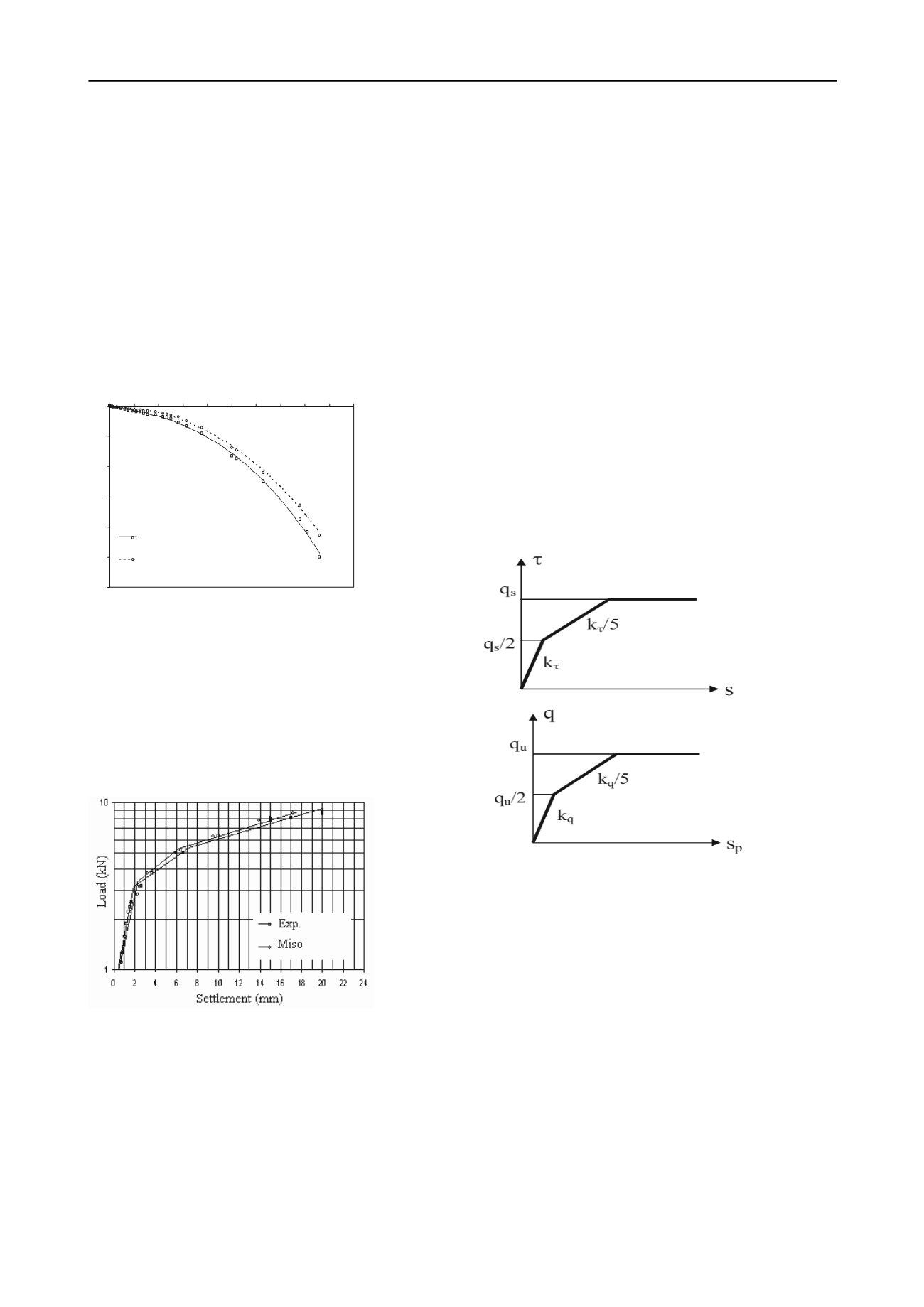

Frank etal., (1991) have studied the load settlement response of

two piles forming a part of a bridge foundation. and had

established that their behaviour can be predicted by conducting

the pressuremeter test.Their prediction of pile behaviour is

based on a tri-linear relationship for the skin friction

mobilisation based on the pressuremeter tests The model they

had used is given in Figure 6.

The first segment has a constant slope .The slope of the

second line as more flat and third segment represents the

mobilisation of total skin friction. A typical tri-linear model of

shaft friction mobilisation. The end of the second part is the

limiting value of the friction .The evaluation of the friction is

done in their case based on LCPC-SETRA (1985) RULES. The

slopes of the lines depend upon the pressuremeter modulus and

radius of the pile. The prediction experimental load distribution

given by them has a similar trend as predicted by the numerical

analyses of the 1g model tests.

8. APPLICABILITY TO PILED RAFT DESIGN

Figure 7 and Figure 8 present the shaft stress distribution over

the length of the pile by pressuremeter test results and from the

numerical analyses of the 1g model tests. it is seen that the trend

of the shaft stress distribution obtained from both the cases

agree closely,indicating that the tri-linear model assumed in the

analyses of the pressuremeter results and the actual behaviour of

piled raft obtained from the 1g model are identical.