2672

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

It is always recognized in geotechnical engineering that the

most difficult part is the evaluation of the in-situ parameters

particularly the elastic modulus. In most of the cases, such

parameters are obtained either from laboratory tests or from

standard correlations between tests like SPT and Es values,

which can affect the accuracy of results. However over the past

few years there is a considerable shift from the laboratory

testing to in-situ testing and this has led to the use of the results

from in situ tests such as CPT and pressuremeter tests

extensively to determine the stress strain characteristics and

essential parameters like the in-situ elastic modulus of the soil

over the length of the pile. A well tried procedure for predicting

such parameters along with the shaft friction development has

been published by Roger Frank et al (1991) using pressuremeter

tests. Therefore it was felt necessary to study whether such

predictions can be used to evaluate the numerical details such as

the number of piles, length, diameter, and layout required for

the design of the piled raft.

0

2

4

6

8

10

12

14

16

18

20

22

0 1 2 3 4 5 6 7 8 9 10

LOAD, kN

SETTLEMENT,mm

PLAINRAFT

200 mm

120 mm

100 mm

75 mm

d = 10mm

t = 8mm

N= 21

R.A. = 36º

D= 200mm

Bed = MD

Piled raft

Pile length

3. SCOPE OF WORK

With the above in mind it was decided to study the various

options available to idealise the piled raft model which would

be amenable for a simple numerical procedure and will give the

load settlement, settlement reduction and load sharing behaviour

of the piled raft. Further in order to evaluate the elastic modulus

and other parameters over the pile depth various in-situ test

options were also studied. It was found that the equivalent pier

approach would be the most suitable approach for modelling the

piled raft. The paper presents the details of the study and the

conclusions of the study.

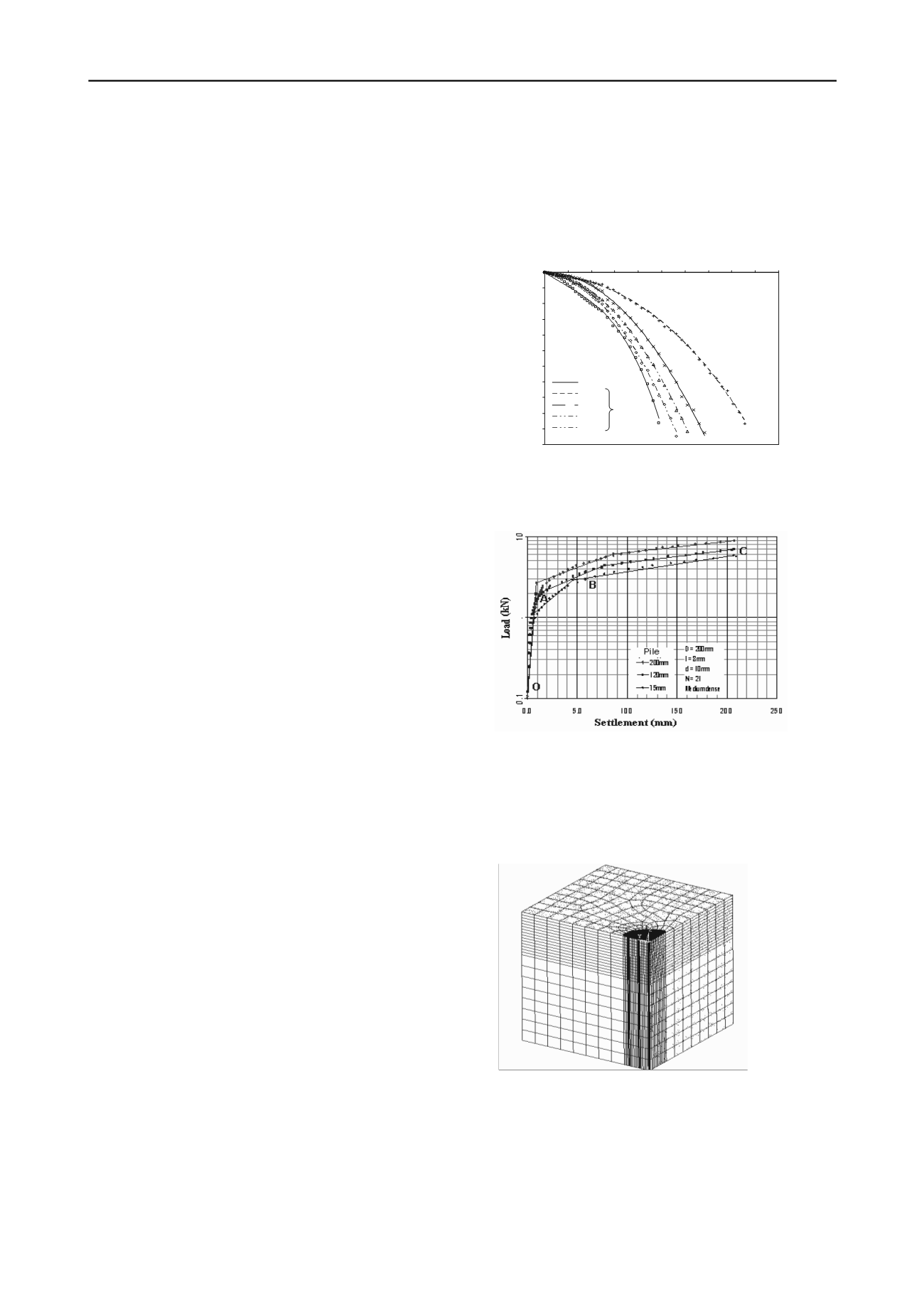

Figure 1. Load-Settlement Response of Circular Piled Raft

with Various Pile Lengths

4. THE STUDY

In the design of piled raft the requirement is the settlement

reduction and the data for the design is the load shared by the

raft and the pile group. It is only from the group capacity

required, the number of piles required, diameter and the length

can be evaluated. In order to study the load settlement response,

a series of 1g small scale model tests were carried out on

circular and square shaped piled raft placed on sand bed. Poorly

graded sand was rained in pre-calibrated manner so that the

required densities could be achieved; the tests were carried out

on unpiled raft, free standing pile group and piled raft.

Extensive parametric studies were also carried out but the

presentation is restricted to the load settlement and load sharing

response typically for circular piled raft under medium dense

bed condition. The studies showed that the performance of the

piled raft was identical in all the other cases. Details of the

models test set up and other details are presented elsewhere

(Balakumar etal., 2005)

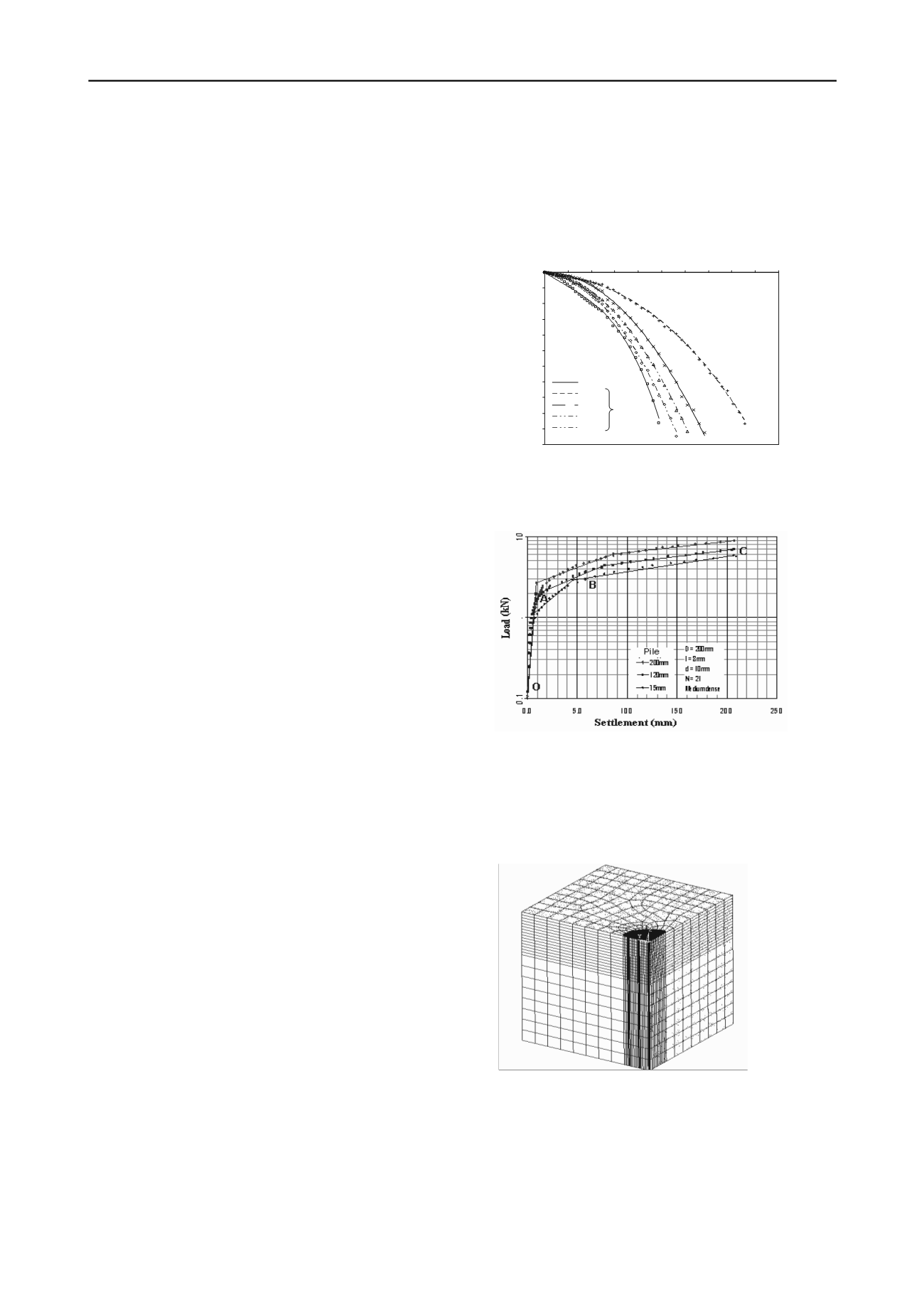

Figure 2. Characteristic Response of Piled Raft

5. LOAD SETTLEMENT AND LOAD SHARING

RESPONSE.

Figure 3. Finite Element Mesh of a Circular Piled

Figure 1 presents the load settlement response of circular piled

raft with varying pile lengths and and figure presents the

charecterised form of the load settlement response.It is clearly

seen that at any given settlement the load taken by the piled raft

is more than the unpiled raft for the corresponding settlement.It

is seen that the load taken by the piled raft with pile length of

200mm is far higher than the other lengths namely

75mm,100mm and 120mm. The typical characterisation curve

of the piled raft shown with various pile lengths are given in

Figure 2 for a pile diameter of 10 mm, which shows that

irrespective of the pile length, the behaviour has three phases.

Although the settlement up to which the linear elastic stage

(portion OA of the curve) remains same as 1mm, the load

corresponding to this varies. As can be seen at higher length the

linear behaviour extends nearly upto 30% of the load taken by

the piled raft corresponding to settlement equal to 10% of the

pile length. The second stage of the curve AB is the stage where

the behaviour tends to become elasto- plastic, which extends up

to a settlement level 9 mm for 200 mm long pile, 7.5 mm for

120 mm long pile and 4.5 mm for 75 mm long pile.

To have better understanding on load sharing between the

raft and pile group of piled raft, three dimensional nonlinear

analysis was carried out using ANSYS code. Only quarter

model of piled raft was analysed taking advantage of the

symmetry (Figure 3).

The bed density was kept as medium dense with φ = 37.5°

and dry unit weight = 15.5 kN/m3. MISO material model was

used for the soil. The continuum was modelled using solid 45

elements with three degrees of freedom at each node. In the

analysis the bed dimensions were kept same as that of the model

tested in the laboratory. The raft and piles were also modelled as

solid 45 elements in order to maintain the elements