2669

Technical Committee 212 /

Comité technique 212

methods, while offering good agreement with the more rigorous

3D computational methods for certain pile-soil configurations.

However, the solution cannot easily model pile installation

effects or soil-pile separation. Additionally, variation of the soil

profile below the pile tip is not included in the formulation. The

formulation was programmed in MATLAB for use in this study.

More details on the theoretical approach can be found Novak

and Aboul-Ella (1978).

3 PARAMETRIC STUDY AND RESULTS

The measured vibration data from full-scale tests were used in

an inverse-analysis framework to calibrate the theoretical soil-

pile model and identify the optimum values for each parameter

in the solution. A sensitivity analysis was first conducted to

determine the relative influence of the various parameters and

estimate their possible range of variation for modeling the

experimental observations. The properties of the pile-cap and

shaker are known relatively accurately, and were therefore

determined not to play a major role in the sensitivity analysis.

Attention was thus focused on the soil-pile interaction

unknowns, including contact conditions and gapping near the

surface, and profiles of soil shear modulus and damping. The

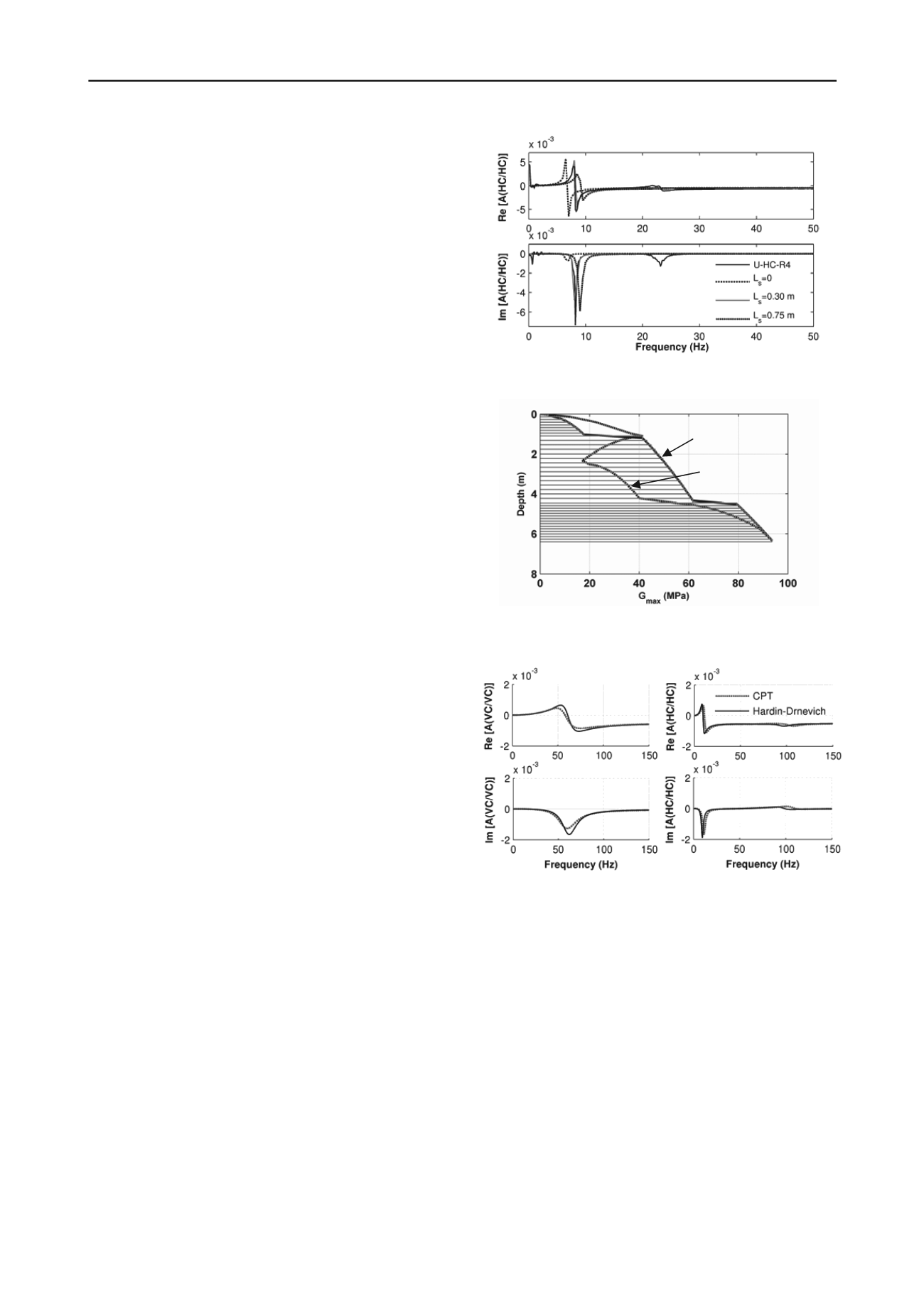

parametric studies indicated that the un-embedded length of the

pile can have a significant effect on the accelerance. Although

the free un-embedded length of the pile can be measured

accurately, slight gapping was observed in the field for pile U.

The sensitivity of accelerance to gapping effects was

therefore examined by increasing the length of the free pile stem

in the theoretical accelerance calculation, while decreasing the

embedded pile length accordingly in the approximate 2D soil-

pile impedance model. Figure 4 illustrates the effect of gapping

on the theoretical accelerance, shown relative to the

experimental HC/HC response for test U-HC-R4. As indicated

in this figure, a 0.3 m soil-pile separation depth was found to

produce an improved fit of the first experimental horizontal-

rocking peak. Due to the non-destructive elastodynamic nature

of the tests, the gapping depth was not observed to vary

significantly between tests. Gapping was not observed for pile I

in the field, likely due to its vibratory installation while the

CDSM zone was still in a liquid state.

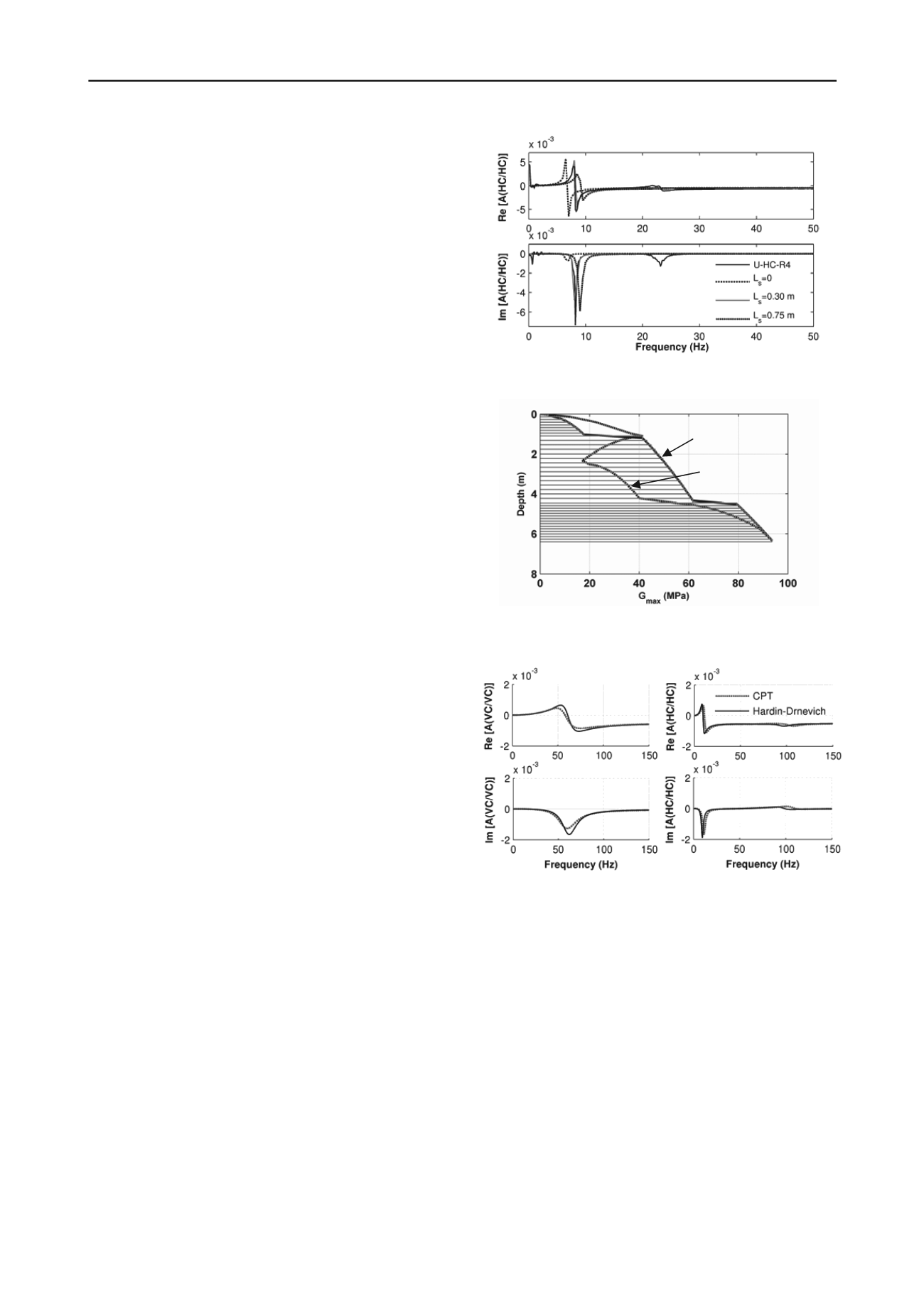

Figure 5 depicts the two shear modulus soil profiles that

were used in the study of the unimproved soil-pile system. The

profile labeled “CPT” was calculated from the CPT data using

correlations to shear wave velocity presented in NCHRP

Synthesis 368 (Mayne, 2007). Since correlations between CPT

resistance and shear-wave velocity are not precise, the input

values for the soil modulus are expected to incur some degree of

error. Therefore, a second shear modulus profile based on

Hardin and Drnevich (1972) was also examined, as shown in

Figure 5. To model the soil damping profile, only three major

layers corresponding to those shown in Figure 1 were

distinguished along the length of the pile, compared to 38 finer

layers used in shear modulus profiles.

Figure 6 demonstrates the effect of the two shear modulus

profiles on the theoretical vertical and horizontal-rocking

responses in VC and HC tests, respectively. The CPT profile

generates a softer response in the vertical mode of vibration

while yielding a slightly increased stiffness for the horizontal

mode. This may be expected as the CPT-based modulus profile

Figure 4. Effect of soil-pile separation depth on HC/HC response for

pile U in native unimproved soil.

Figure 5. Two 38-layer shear modulus profiles used in the analyses

based on interpretation of field CPT data and Hardin and Drnevich

(1972).

Hardin and Drnevich

CPT

is softer overall, but is stiffer near the surface region which has

a greater influence on the bending behavior.

Both the vertical and horizontal rocking modes of the pile in

the native unimproved soft clay can be nearly captured using the

Hardin & Drnevich shear modulus profile together with the

0.30 m separation zone, but require application of scale factors

to the modulus and damping within the three major layers

shown in Figure 1. Figure 7 illustrates such a comparison using

modulus reduction factors of 0.8, 0.8 and 0.5 for the top, middle

and bottom layers, respectively, while increasing the damping in

all layers by a factor of 10. The peak frequency of the vertical

mode is fit reasonably well, but the experimental vertical

response exhibits some deviation from the theoretical solution at

higher frequencies. This is assumed to be a relic of a higher

mode of the shaker’s stationary base frame which does not

behave as a perfectly rigid body. The first peak for the

horizontal response matches very well, although this is difficult

to see in Figure 7 as the experimental and theoretical curves are

nearly coincident at this frequency.

Figure 6. Effect of the two shear modulus profiles of Figure 5 on

theoretical vertical response (left) and horizontal response (right).