2661

Technical Committee 212 /

Comité technique 212

strain (

=0.1%) derived from the stiffness degradation curves

proposed by Seed & Idriss 1970 for cohesionless soils.

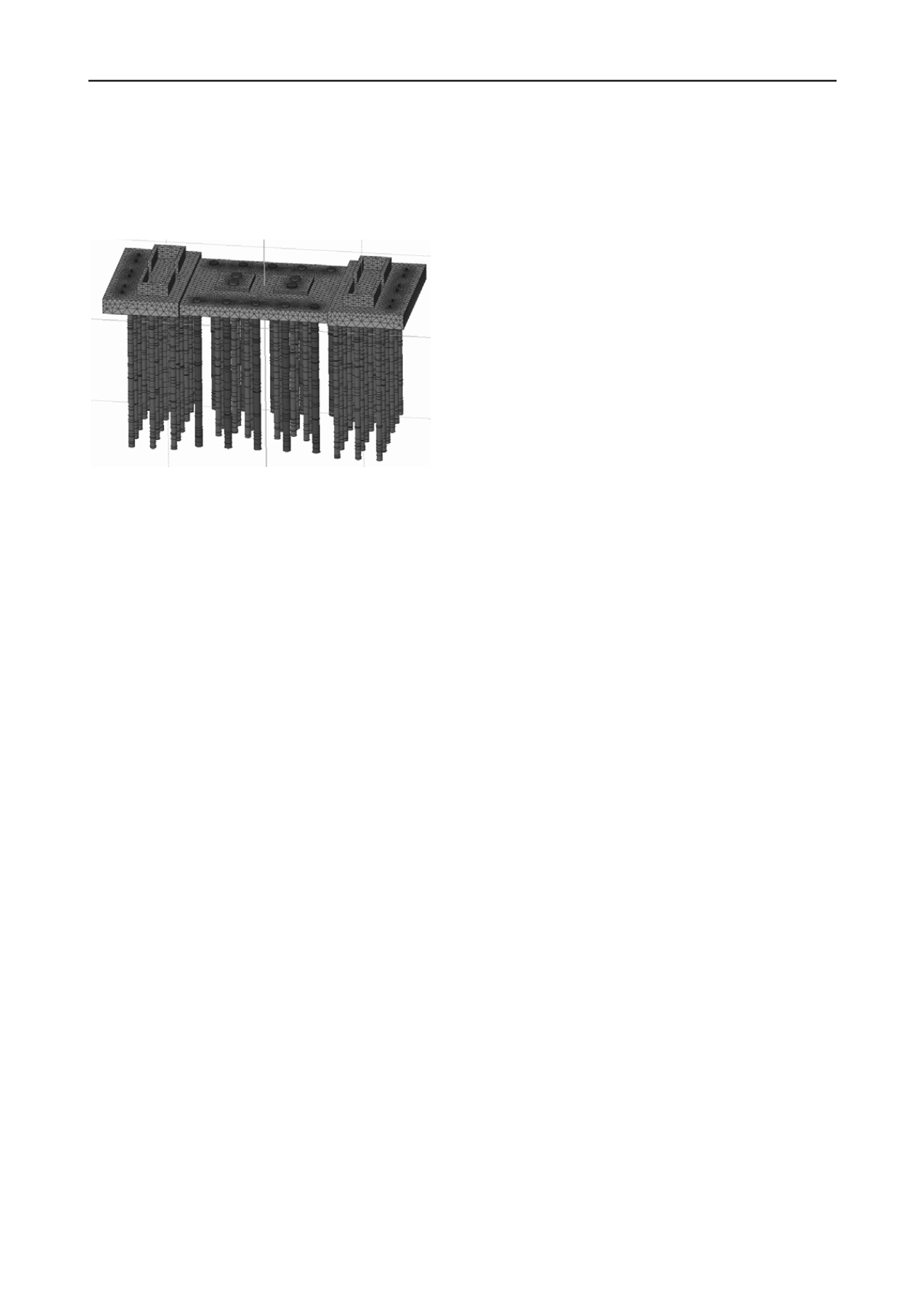

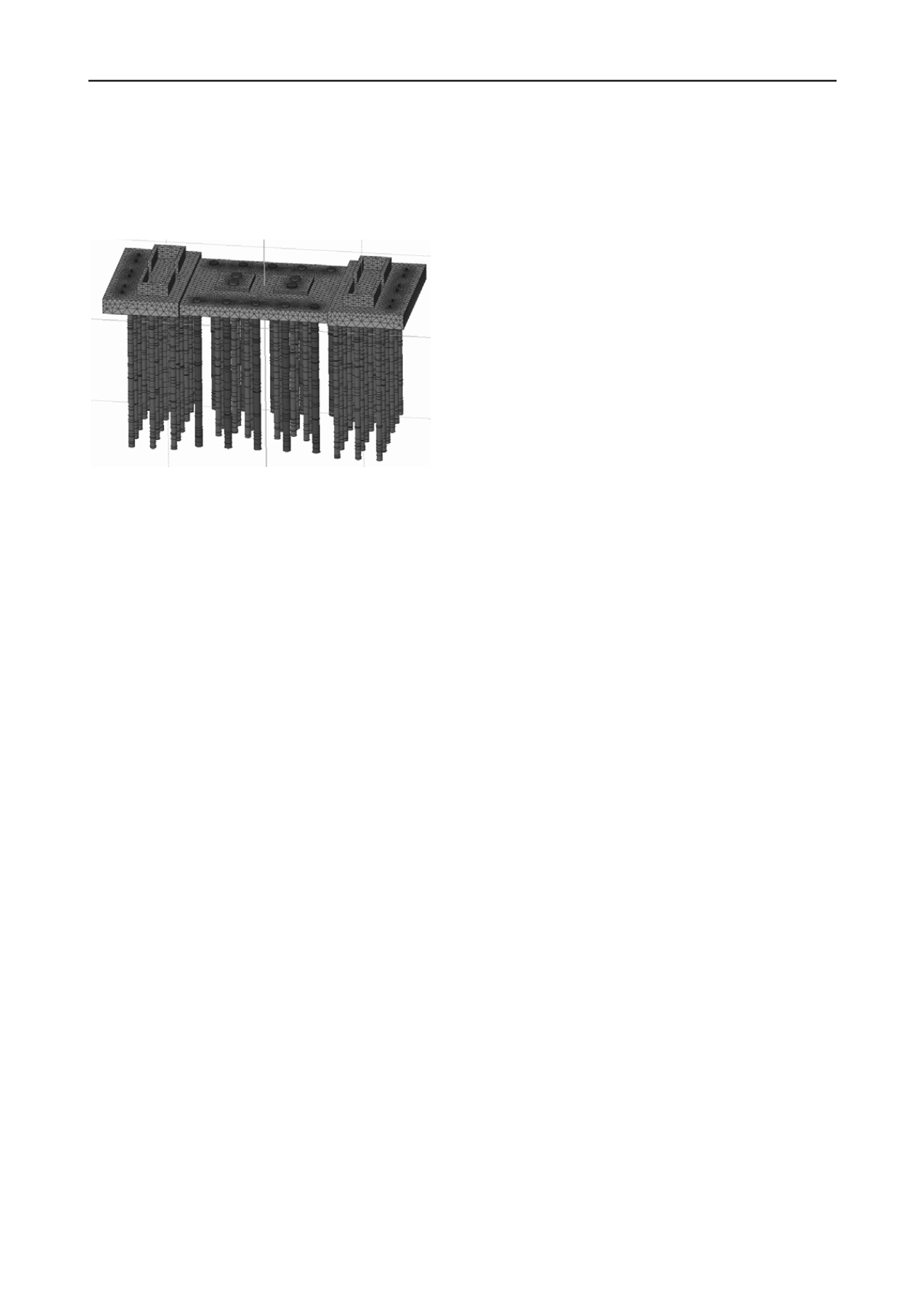

The GSA model was compared with a full 3D FE analysis

developed with MIDAS GTS (Figure 5) which provided similar

settlements, pile axial loads and raft stresses.

Simplified methods are used during the initial optioneering

phase to develop a solution which can then be analysed with

more rigorous tools.

GSA is a reliable and efficient tool for the final design stages

which has shown to match the results of a parallel full 3D FE

piled raft model.

Pile length to equivalent circular raft radius ratio and pile group-

raft area ratio are important elements to consider during design.

A FoS<2 on piles results in higher working load in piles than

would otherwise be the case; this requires additional

consideration for their structural design.

Internal actions on the upper part of the piles are reduced by

avoiding a structural connection between piles and raft without

significantly affecting the raft behaviour. Limiting the

mobilisation of the piles’ shaft resistance minimises the

sensitivity of the raft behaviour with respect to workmanship

problems and local variations of soil conditions.

Assessment of the total settlements requires consideration of

time-dependant phenomena.

Piled rafts can offer a cost-effective foundation solution for

high-rise buildings.

Figure 5. MIDAS GTS 3D FE model of the piled raft.

Creep effects of the concrete in the raft and piles were taken

into account as these affect the long term behaviour of the

foundation. A reduction factor of the young modulus of 1+φ

∞

was adopted with φ

∞

=0.90 for the raft and 0.76 for the piles. In

order to limit bending moments in the top of the piles due to raft

deflection, no structural connection between the raft and the pile

head was provided.

6 ACKNOWLEDGEMENTS

The authors would like to thank Duncan Nicholson, Alessandro

Baliva, and Matteo Minno for their contribution as well as

Marco Beccati for his support from the client’s side.

The piled raft behaviour under horizontal loads was analysed

with PIGLET (Randolph 2006) and the Oasys software ALP

and PDISP.

7 REFERENCES

Burland and Burbidge 1985. Settlement of foundations on sand and

gravel. Proc. ICE, part 1.

The effect of wind induced cyclic actions was estimated

according to the methods described by O’Riordan 1991

(settlements) and Poulos & Davids 2005 (pile stiffness

degradation).

Burland J., Chapman T., Skinner H. D. and Brown M. 2012. Manual of

Geotechnical Engineering, Institution of Civil Engineers.

Half of the maximum raft settlements were estimated to occur

during construction, 33% were associated to creep, 13% to

cyclic loading and 4% to planned nearby buildings. The

potential for tilting due to variations in thickness of the cohesive

layers was estimated to be negligible.

Decreto Ministeriale 14.1.2008 del Ministero delle Infrastrutture.

“Nuove norme tecniche per le costruzioni”. S.O. n. 30 alla G.U. del

4.2.2008, n. 29.

Fleming G.W.K. 1992. A new method for single pile settlement

prediction and Analysis, Geotechnique 42, No. 3 pp 411-425

Koutsoftas, D., Fisher, J. 1980. Dynamic properties of two marine clays,

ASCE J. Geotech Division 106 (GT6), pp. 145-157.

The load percentage split between the raft and the piles

estimated from the FE analyses is 35/65: this matches well with

that proposed by Mandolini

et al.

2005 for (s/d)/(A

g

/A)=4.75.

Mandolini A. 2003. Design of piled raft foundations: Practice and

Development, Design of foundations on bored and auger piles, Van

Impe ed., Rotterdam.

The 1.2m diameter piles have a factor of safety (FoS) ranging

between 1.45 and 1.65, and the 1.5m diameter piles between

1.55 and 1.75.

Mandolini A., Russo G. and Viggiani C. 2005. Pile Foundations:

Experimental investigations, analysis and design.

ICSMGE

, Osaka.

MIDAS GTS Scientific Manual.

Oasys Ltd, Oasys Geo Suite v 19.1 ALP, GSA and PDISP Software

Manual, London 2010.

Whilst stringent checks of pile construction (eg. cleaning of the

base) are needed to ensure that the specified requirements are

met, limiting the mobilisation of the piles shaft resistance

minimises the sensitivity of the raft behaviour with respect to

workmanship problems and local variations of soil conditions.

O’Riordan N.J. 1991. Effects of cyclic loading on the long term

settlements of structures, Cyclic loading of soils, Blackie.

Poulos H. G. 2001. Piled-raft foundation: design and applications.

Geotechnique, 51(2), 95-113.

Poulos H. G. and Davids A. J. 2005. Foundation design for the Emirates

Twin Towers Dubai, Canadian Geotechnical Journal, 42, 716-730.

Accepting a FoS<2 for the piles required the use of a higher

concrete class (C32/40) than in conventional piled foundations:

this has cost implications and needs to be considered at

optioneering stage. The overall cost of the piled raft was

estimated to be 35-45% lower than that of a simple raft; the

piled raft requires 50-60% less concrete and 35-45% less steel.

The cost of the piles is 20% of the total foundation cost.

Randolph M.F. 2006. PIGLET: Analysis and design of pile groups.

Users’ Manual, Version 5.2, Univ. Western Australia, Perth.

Reul O. and Randolph M.F. 2004. Design strategies for piled rafts

subjected to nonuniform vertical loading, Journal of Geotechnical

and Geoenvironmental Engineering, ASCE.

Seed H. and Idriss I. 1970. Soil moduli and damping factors for

dynamic response analysis. EERC report n.70-10. Berkeley, CA.

Stroud, M.A. 1988. The standard penetration test – its application and

interpretation.

The piled raft has been constructed and is fully instrumented.

5 CONCLUSIONS

Mixed foundations are covered by the Italian Construction Code

which allows the design of piles as settlement reducers if the

raft alone can comply with the ULS requirements.