2664

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

This paper investigates the performance of piled raft

foundations and their load sharing mechanism employing a 3D

finite element model calibrated/verified using geotechnical

centrifuge data.

2 DEVELOPMENT OF FINITE ELEMENT MODEL

The development of the FEM in this study consisted of

three main steps. First, a 3D FEM was established to simulate

the behavior of piled raft foundation considering an appropriate

size mesh and number of elements. Second, the results of a

centrifuge study of piled raft performed by others were used to

calibrate the FEM created in this study. Lastly, the calibrated

FEM was employed to perform a parametric study to evaluate

the effect of different parameters on the overall performance of

piled raft foundation.

0

40

80

120

160

200

0

5

10

15

20

25

Depth (mm)

Cone Tip Resistance, q

c

(MN/m

2

)

2.1

Description of FEM

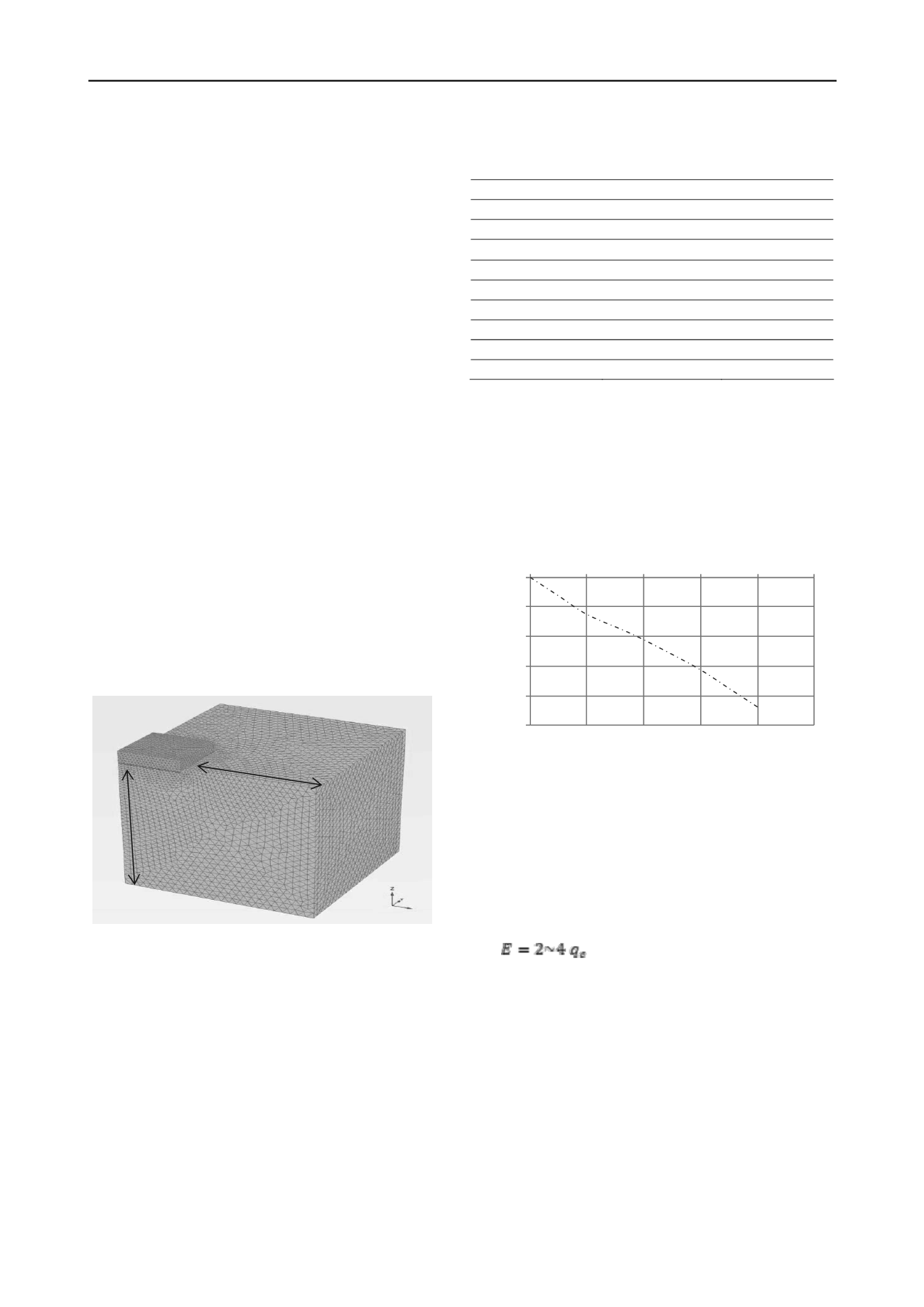

A finite element model (FEM) was developed using the

Plaxis 3D software package (Plaxis bv. 2011). A quarter of the

piled raft foundation system was modeled taking advantages of

symmetry across the x and y-axes to reduce the computation

effort and time. The boundaries of the model were set at a

distance equal to 1.5B~2B (where B is raft width) measured

from the edge of the raft, and the depth of the model was

approximately two times the pile length as shown in Figure 1.

The model was built using about 275,000 3D 10-node

tetrahedral elements. The average size of the element was

approximately 110 mm. The large number of small size

elements assured high accuracy of the results at locations where

non-linear behavior is anticipated (e.g. raft base, pile base and

pile circumference). The load was applied using uniform

prescribed displacement applied at the top of the raft, and the

corresponding load was evaluated.

Figure 1. The FEM used in the current study.

2.2

Centrifuge testing used to calibrate FEM

Horikoshi et al. (2002, 2003a, b) employed geotechnical

centrifuge testing in order to simulate the complicated soil-

structure interaction problem for a piled raft under different

types of loading. The results of the vertical loading case from

their studies will be considered herein to calibrate the 3D finite

element model. The tests were conducted under 50g centrifugal

acceleration. The model consisted of four piles rigidly

connected to the raft. The raft and piles models were made of

aluminum. Toyoura sand was used as the model ground

(Horikoshi et al. 2003a). Table 1 summarizes the dimensions of

the model in both model and prototype scales.

Table 1. The dimensions of the model in both model and prototype

scales.

Model

Prototype (n=50)

Diameter (mm)

10

500

Wall thickness (mm)

1

Solid

Materials

Aluminum

Concrete

Pile length

170 mm

8.5 m

Modulus of Elasticity

71 GPa

41.7 GPa

Raft thickness

40 mm

2.0 m

Raft width (square)

80 mm

4 m

Pile Spacing

40 mm

2 m

Number of piles

4

4

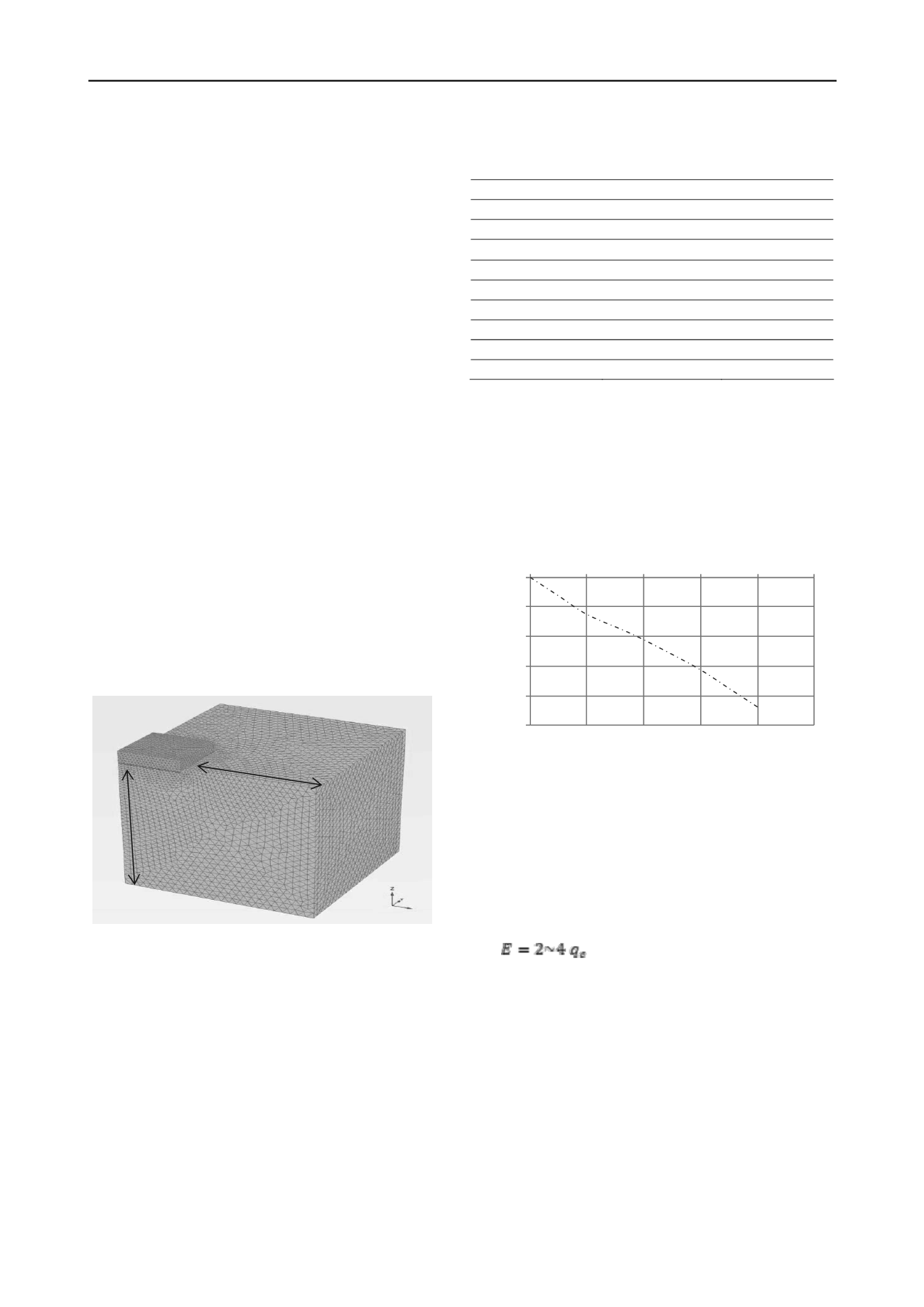

Cone penetration tests (CPT) were performed in-flight to

evaluate the sand strength using a miniature cone penetrometer.

The cone tip resistance profile is shown in Figure 2. It is noted

that the strength (and stiffness) increased with depth, which is

expected for sand soil. This strength profile will be simulated in

the FEM through the input parameters such as the initial

modulus of elasticity and the incremental modulus of elasticity,

which will account for the increase in stiffness with depth.

1.5B~2B

Figure 2. In-flight results for CPT (after Horikoshi et al. (2003a).

2.3

Calibration of FEM

The behavior of the Toyoura sand was simulated using a

linear elastic-perfectly plastic Mohr-Coulomb constitutive

model. Matsumoto et al. (2004b) reported that the peak friction

angle,

, for Toyoura sand is about 45

and the reduction factor,

R

int

, at the interaction surface between the pile and Toyoura

sand is 0.43 (Horikoshi et al., 2003a). The modulus of elasticity

was correlated to the cone tip resistance, q

c

, using the

relationship proposed by Tomlinson (1996), i.e.

2L

p

(1)

All input parameters used in the FEM are listed in Table 2.

The process of calibration was performed by refining the soil

and interface properties in the FEM. This was done by adjusting

the values of the interface reduction factor values at the pile-soil

interface; and the estimated initial modulus of elasticity and

incremental increase of modulus of elasticity with depth (i.e.

within the range stipulated in Eq. 1). After a number of trials,

the FEM a reasonable match with the centrifuge test results was

achieved as demonstrated in Figure 3.

The slight nonlinear behavior observed at relatively low

displacement is attributed to the movement of the pile caused by

slippage at pile-soil interface and increased strains at the pile

base, reaching plastic condition. This piles movement resulted

in more intimate contact between the raft and soil, which