2389

Technical Committee 209 /

Comité technique 209

2...

1 N=0

Q

max

k

l

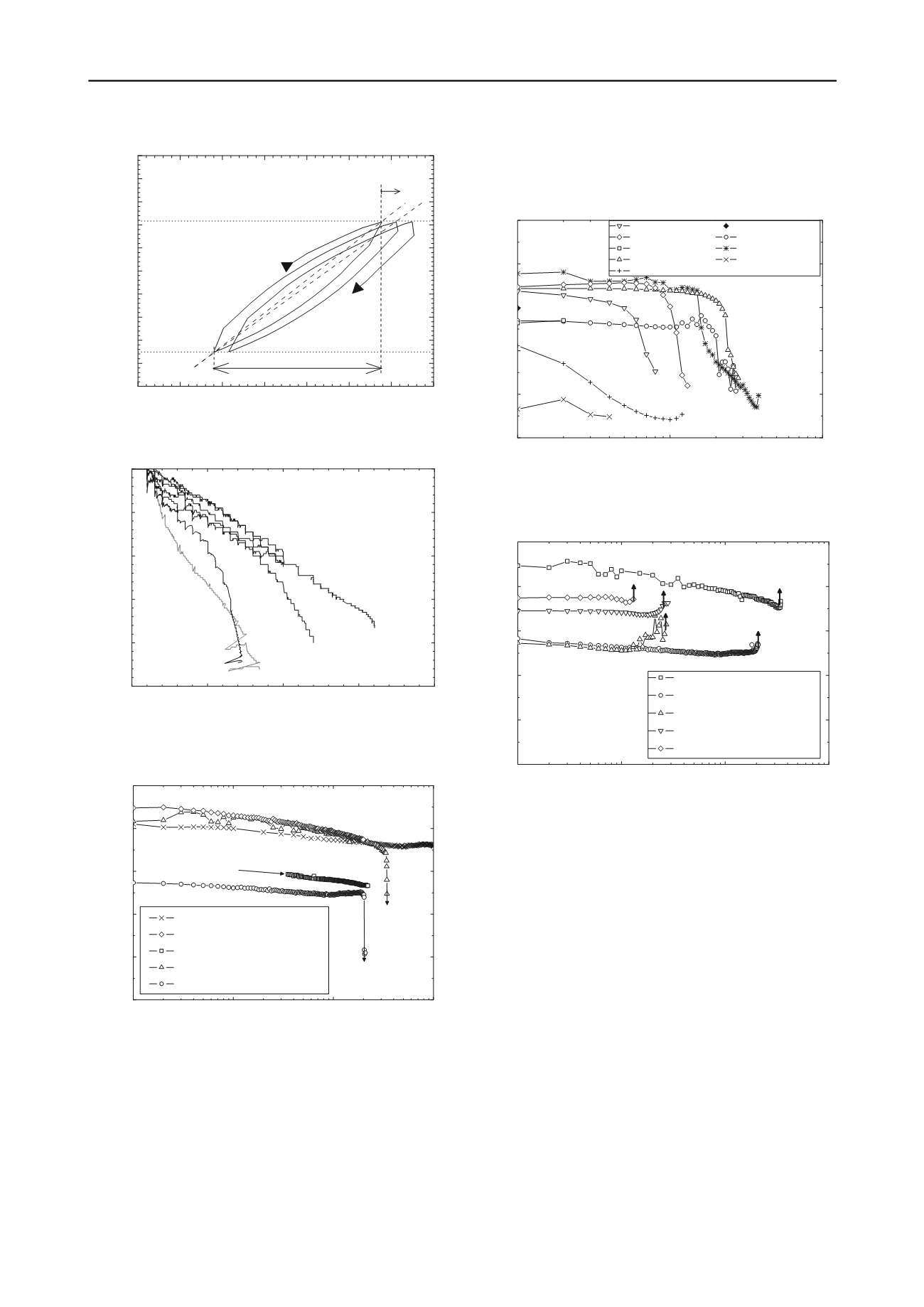

a: Permanent accumulated cyclic displacement

k l : Loading cyclic stiffness

k u : Unloading cyclic stiffness

k

u

Pile head load, Q (kN)

transient displacement, d

a

Displacement, s (mm)

Q

min

Figure 4. Illustration of the stiffness and displacement parameters used

in the analyses

0

5

10

15

20

0.0

0.2

0.4

0.6

0.8

1.0

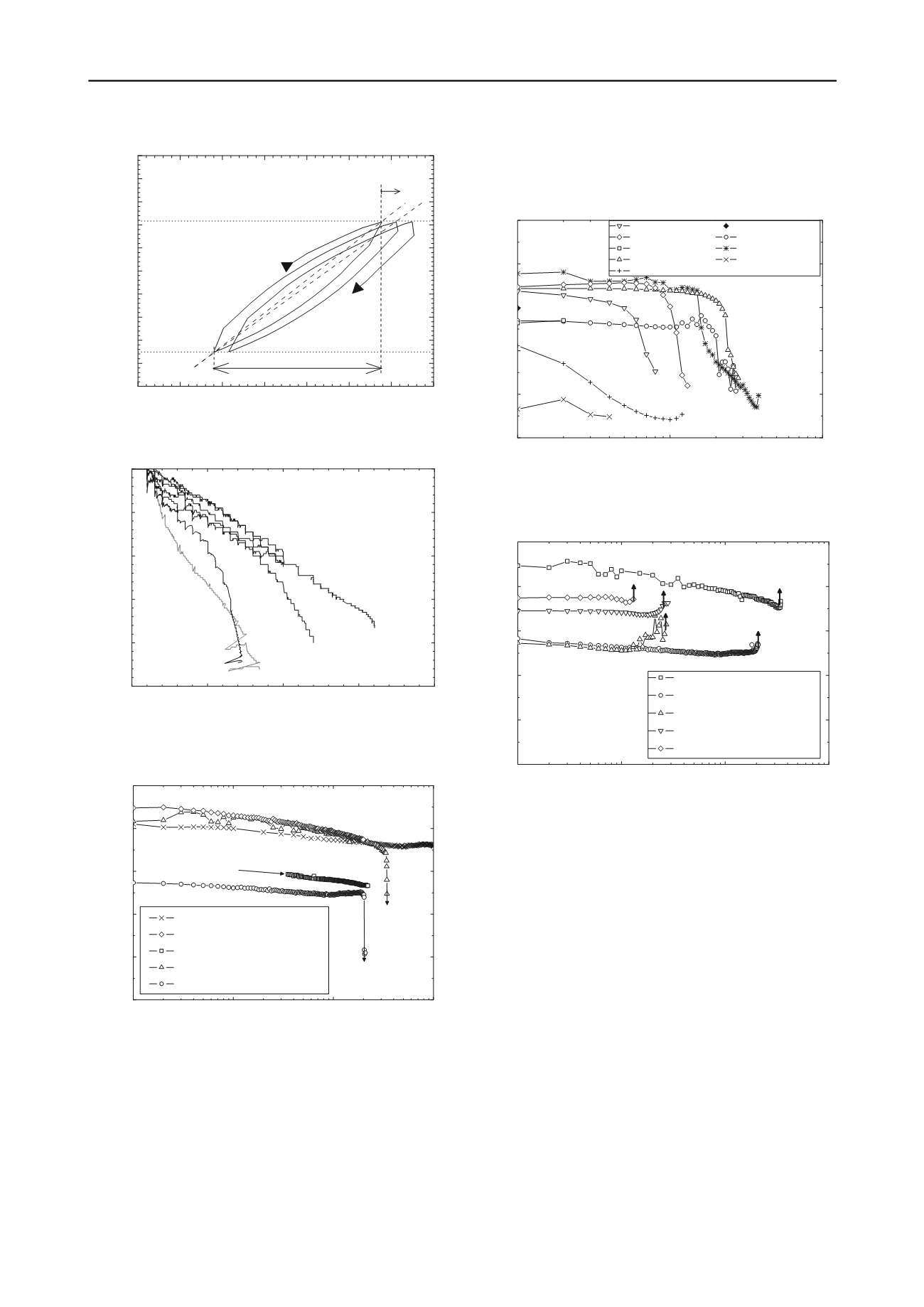

R1

C1

k l /k Ref

Q/Q Ref

R2 - R6

Figure 5. Pile stiffness from the first–time axial static monotonic tension

loadings normalised by the reference stiffnesses against normalised load

1

10

100

1000

0.0

0.2

0.4

0.6

0.8

1.0

Q cyc = 0.3Q T

Q cyc = 0.34Q T

All other Meta-stable tests

Stable test

k

l

/k

Ref

Cycles, N

S 3.R4.CY6; Q cyc = 0.2Q T

MS 2.R3.CY2; Q cyc = 0.3Q T

MS 2.R4.CY2; Q cyc = 0.34Q T

MS 2.R5.CY2; Q cyc = 0.3Q T

MS 3.R6.CY6; Q cyc = 0.42Q T

Data not logged for

the first 34 cycles

Q cyc = 0.42Q T

Figure 6. Axial cyclic loading stiffness k

l

responses normalised by k

Ref

against number of cycles for the stable and meta–stable tests.

The loading stiffness k

l

degradation trends for the unstable

tests (Set 3 of Figure 1) are shown on Figure 7. By definition,

these tests failed with sudden stiffness loss after relatively few

cycles. However, even these piles retained most of their initial

stiffnesses until within ~10 cycles of final failure. Seemingly

anomalous stiffness behaviour is observed towards failure in

some one–way meta-stable and unstable loading tests when

stiffnesses are defined from the unloading cycle phase k

u

,

Figure 8. This reversal in normalised stiffness results from an

increased opening-up of the load-unload hysteresis loops as

cyclic failure approaches with more plastic displacements

accumulating on the loading loops leading to the progressively

decreasing secant loading stiffnesses and apparently stiffer

behaviour on unloading as cyclic loading approaches failure.

1

10

100

0.0

0.2

0.4

0.6

0.8

1.0

k

l

/k

Ref

Cycles, N

US 3.R2.CY2 (0.40)

US 2.R6.CY2 (0.36)

US 2.R3.CY3 (0.46)

US 2.R6.CY4 (0.36)

US 2.R4.CY4 (0.44)

US 2.C1.CY3 (0.74)

US 2.R5.CY3 (0.35)

US 2.C1.CY4 (0.72)

US 2.C1.CY5 (0.66)

All Unstable tests

Figure 7. Axial cyclic loading stiffness k

l

responses normalised by k

Ref

against number of cycles for the unstable tests.

1

10

100

1000

0.0

0.2

0.4

0.6

0.8

1.0

k u /k Ref

Cycles, N

MS 2.R5.CY2 Q

cyc

= 0.30Q

T

MS 3.R6.CY6 Q

cyc

= 0.42Q

T

US 2.R6.CY4 Q

cyc

= 0.44Q

T

US 2.R5.CY3 Q

cyc

= 0.35Q

T

US 2.R3.CY3 Q

cyc

= 0.35Q

T

Figure 8. Axial cyclic unloading stiffness k

u

responses normalised by

k

Ref

against number of cycles for selected metastable and unstable tests.

4.3 Accumulated cyclic displacements

The patterns of pile head displacement accumulation for the

stable and meta–stable cyclic tests are shown on Figure 9. Also

shown are the reference lines related to the predefined

thresholds for stable, metastable and unstable accumulated

displacements rates. An almost static accumulated displacement

trend was observed in the single fully stable loading test

3.R4.CY6. The meta–stable tests 2.R3.CY2 and 2.R4.CY2

developed higher, but steady displacement rates >

1mm/100cycles while the other two meta–stable tests 2.R5.CY2

and 3.R6.CY6 displaced by > 1mm/10cycles. A range of

responses is evident for the unstable loading tests summarised

in Figure 10 which develop displacement rates > 1mm/10cycles.

While the cyclic stiffness patterns varied principally as a

function of the applied cyclic amplitudes Q

cyclic

, the

accumulated cyclic displacement patterns depended on both the

normalised mean (Q

mean

/Q

T

) and cyclic (Q

cyclic

/Q

T

) loads.

Rimoy et al. (2013) demonstrate the interactive effects of the

loading components Q

cyclic

and Q

mean

by considering the

accumulated displacements developed after 3, 10, 30, 100, 200,

and 300 cycles to produce tentative 3D surfaces equivalent to

displacements of 2%, 0.2% or 0.02% pile diameter, Figure 11.

The accumulated displacement trends flatten progressively as N

increases. The zero cyclic effect boundary was set at Q

cyclic

/Q

T

=