2388

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 SCOPE OF STUDY

Seven full-scale 457mm diameter, 13.5mm wall thickness

(increased to 20mm over top 2.5m), open-ended steel pipe-piles,

six (R1 – R6) with embedded lengths around 19m and one (C1)

driven to 10m were installed as part of the Grouted Offshore

Piles for Alternating Loading (GOPAL) project (Parker et al.

1999) in a flat area close to Dunkerque Port Ouest Industrial

Zone. The site has a relatively deep profile of dense sand,

Figure 2. Chow (1997) reported static and cyclic pile tests

incorporating pore pressure measurements that showed a fully

drained response over the loading rates applied. The piles’

cyclic capacity trends have been reported by Jardine and

Standing (2000, 2012), while Jardine et al. (2006) reported the

static tension capacity–time trends.

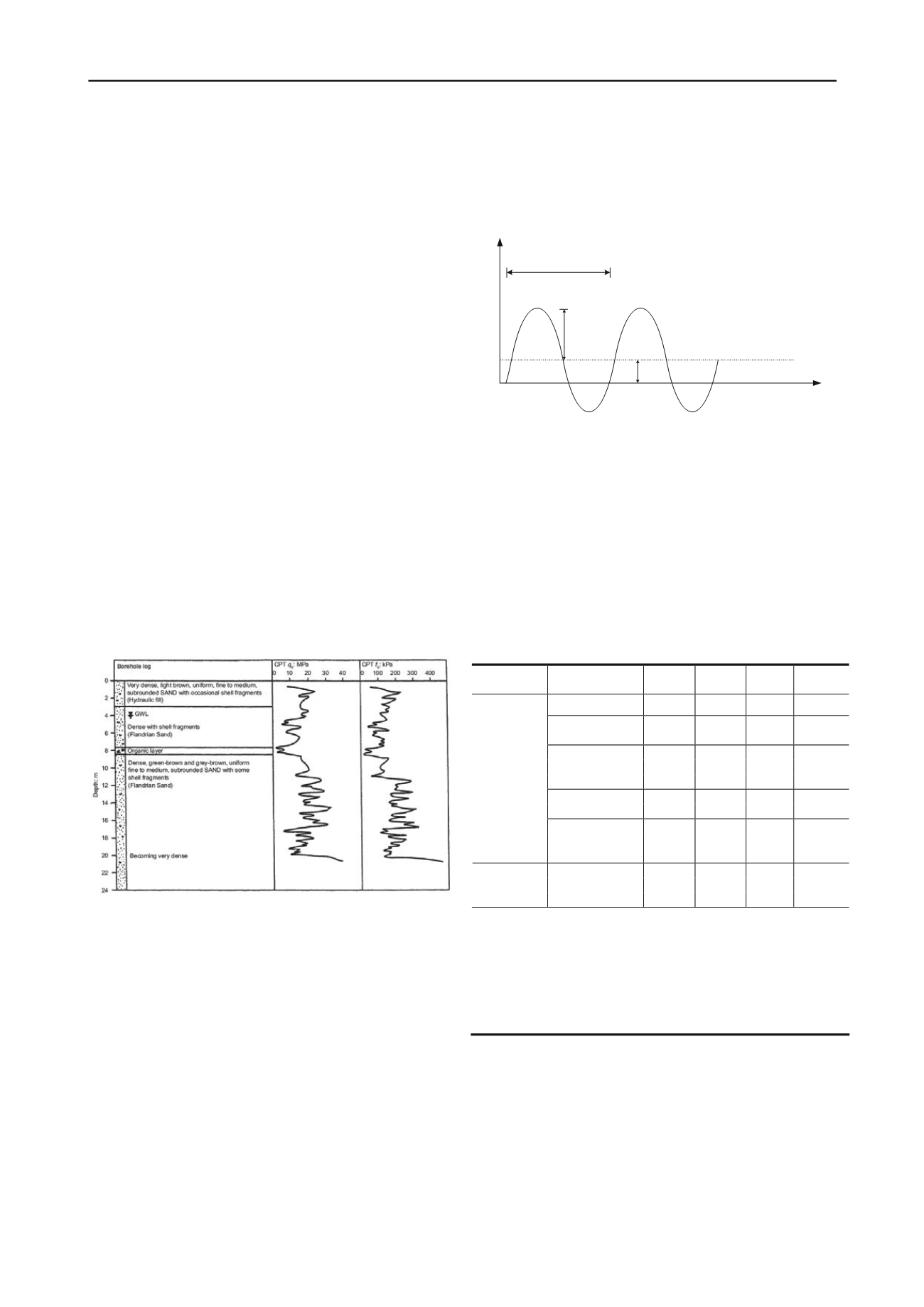

3 TEST PROGRAMME

Jardine et al. (2006) detail the testing arrangements, pile head

load control and displacement measurements. The cyclic test

programme is detailed on Table 1; load cycles were performed

with periods between 1 to 2 minutes depending on the pile

response. The axial cyclic load was applied in approximately

sine wave forms as defined in Figure 3. The load-controlled

tests involving only tensile pile head loads are termed ‘one–

way’ while cycles ranging from tension to compression are

referred to as ‘two–way’; tension loads and upward

displacement responses are taken as positive throughout.

Reference static tension tests to failure were conducted after

most of the cyclic tests to assess the effects on the applied axial

cyclic loading on the operational static tension (shaft) capacity

and isolate any effects of previous (static or cyclic) loading

phases from the current axial cyclic behaviour.

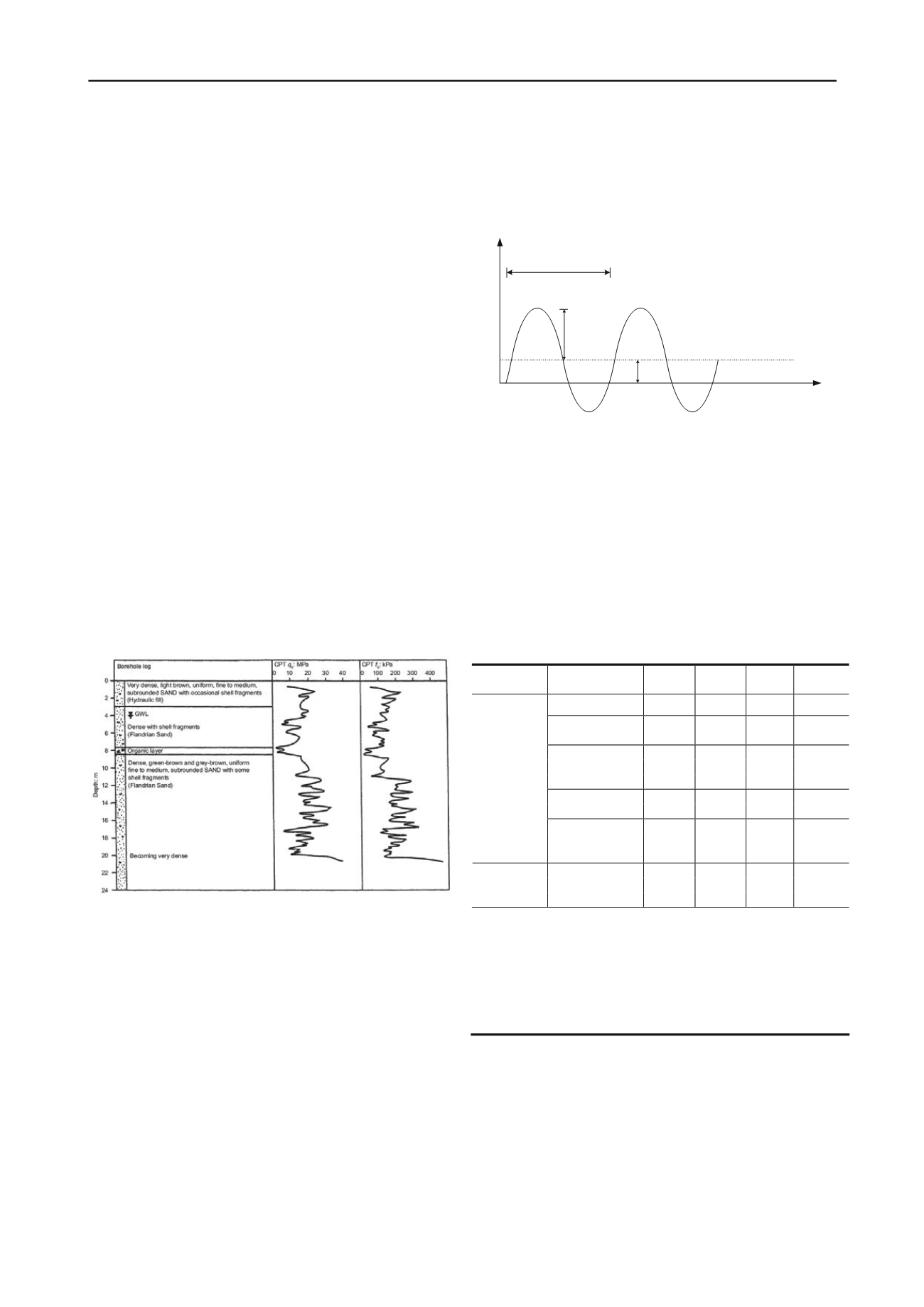

Figure 2. Typical site profile for Imperial College test site (Chow 1997)

4 RESULTS AND INTERPRETATION

4.1 Cyclic failure criteria

The axial cycling displacement response is classified as stable

(S), meta–stable (MS) or unstable (US) according to the

following criteria.

Stable

response signifies low and stabilising

cyclic displacements that remain below 0.01 the pile diameter,

D, and show slow rates of change ≤ 1mm/1000 cycles (N) up to

N ≥ 1000 without causing loss in operational static shaft

capacity. Tests with

meta–stable

responses accumulate > 0.01D

displacements but < 0.1D with moderate rates (1mm/1000

cycles < rates ≤ 1mm/10 cycles) potentially leading to some

degradation of the operational static shaft capacity but not

causing failure within 100 cycles.

Unstable

responses lead to

cyclic failure within 100 cycles, involving either accumulated

permanent cyclic displacements > 0.1D or rates of accumulation

of permanent cyclic displacements that exceed 1mm/10cycles

with potentially very significant shaft degradation.

The fourteen cyclic tests gave a range of outcomes with one

stable (set 1), four meta–stable (set 2) and nine unstable (set 3)

responses indicated in Figure 1. The following sections analyse

the cyclic stiffnesses and accumulated displacements seen in

these three modes using the terms defined in Figure 4.

Figure 3. Load–controlled axial cycling illustrated (Tsuha et al. 2012)

4.2 Pile axial cyclic stiffness

The variations of the piles’ secant stiffness, k = ΔQ/Δs, under

first-time static tension loading are shown on Figure 5

represented by the stiffnesses ratio, k/k

Ref

, against the load ratio,

Q/Q

Ref

, where k

Ref

is the pile stiffness at the first monotonic

load step, Q

Ref

, in the first-time tension tests. The 19m long

piles (R2 to R6) follow common trends although one ‘younger’

and lower ultimate capacity 19m long pile R1 degraded more

rapidly than the others as did the shorter (10m long) pile C1.

Table 1. Axial cyclic loading test programme: after Jardine & Standing

2000)

(

Test mode

Test code

Q

cyclic

(kN)

Q

mean

(kN)

Q

T

(kN)

N

f

US 3.R2.CY2

1000

1000

2500

9

MS 2.R3.CY2

700

700

2315

200+

US 2.R3.CY3

950

950

2050

13

MS 2.R4.CY2

1000

1000

2960

221+

US 2.R4.CY4

750

1250

2000

3

S 3.R4.CY6

400

405

2110

1000+

MS 2.R5.CY2

750

1250

2465

345

US 2.R5.CY3

700

700

2000

27

US 2.R6.CY2

750

1250

2000

1

US 2.R6.CY4

700

700

1585

24

One–way

MS 3.R6.CY6

700

700

1650

206

US 2.C1.CY3

620

-40

840

41

US 2.C1.CY4

445

165

620

1

Two–way

US 2.C1.CY5

410

10

620

12

Test code explanation:

XX M.YY.ZZN:

XX = Pile response mode (S - Stable, MS – Meta-stable, US –

Unstable)

M = Testing campaign phase (out of 3)

YY = Pile name (C1, R2 – R6)

ZZ = Test type (T – Static tension, C - Static compression, CY – Axial

cyclic)

N = Test number on the pile in sequence from installation

Figure 6 examines the axial cyclic stiffness trends for the

stable and meta–stable (sets 1 & 2 on Figure 1). The initial

normalised stiffness values (i.e. k

l

/k

Ref

at N = 1) generally

decreases as the proportion of applied Q

max

to Q

T

increases. In

the stable loading test 3.R4.CY6, it can be seen that continued

cycling leads to only a marginal stiffness decrease (12%) over

1000 cycles, with stiffness values stabilising and then

marginally increasing after 200 cycles. Compared with this, the

four meta–stable loading tests showed similarly mild stiffness

degradation before manifesting sharply accelerating stiffness

degradation as the piles approached cyclic failure under the

conditions given in Table 1.