1728

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The maintenance costs and the status of a structure are strongly

related and are shown in Figure 1 (Wicke et al. 2001). To

achieve a constant status of a structure (line A´) the

maintenance costs of line A are necessary. If less maintenance

costs are spent (line B) the status of a structure is decreasing

(line B´) until the structure is useless. To avoid a total damage

of the structure at a late point of time (line C´) enormous

maintenance costs are necessary (line C). In this case the

maintenance costs are much higher than the savings before.

The objective of the continuous inspection and supervision is

the economic supply and maintenance of the structures. This

means a long-term indemnification of stability, traffic safety

and durability. The maintenance costs and the status of a

structure are strongly related and are shown in Figure 1 (Wicke

et al. 2001).

To achieve a constant status of a structure (line A´) the

maintenance costs of line A are necessary. If less maintenance

costs are spent (line B) the status of a structure is decreasing

(line B´) until the structure is useless. To avoid a total damage

of the structure at a late point of time (line C´) enormous

maintenance costs are necessary (line C). In this case the

maintenance costs are much higher than the savings before.

For engineering inspection and supervision of tunnels and

underground stations of urban metro systems no standards and

regulations

are

defined

(Verband

Deutscher

Verkehrsunternehmen 2005). Depending on the type of

construction, age, status, load impact and the soil and

groundwater

conditions

for

different

underground

infrastructures results a different scope of engineering

inspection and supervision. Regarding this fact cities like

Berlin, Hamburg, Essen and Vienna developed their own

regulations. These regulations base on:

DIN 1076 (Deutsches Institut für Normung 1999)

BOStrab (Bundesministerium für Verkehr 2007)

RiL 853 (DB Netz AG 2011)

SIA 469 (Schweizerischer Ingenieur- und Architektenverein

1997)

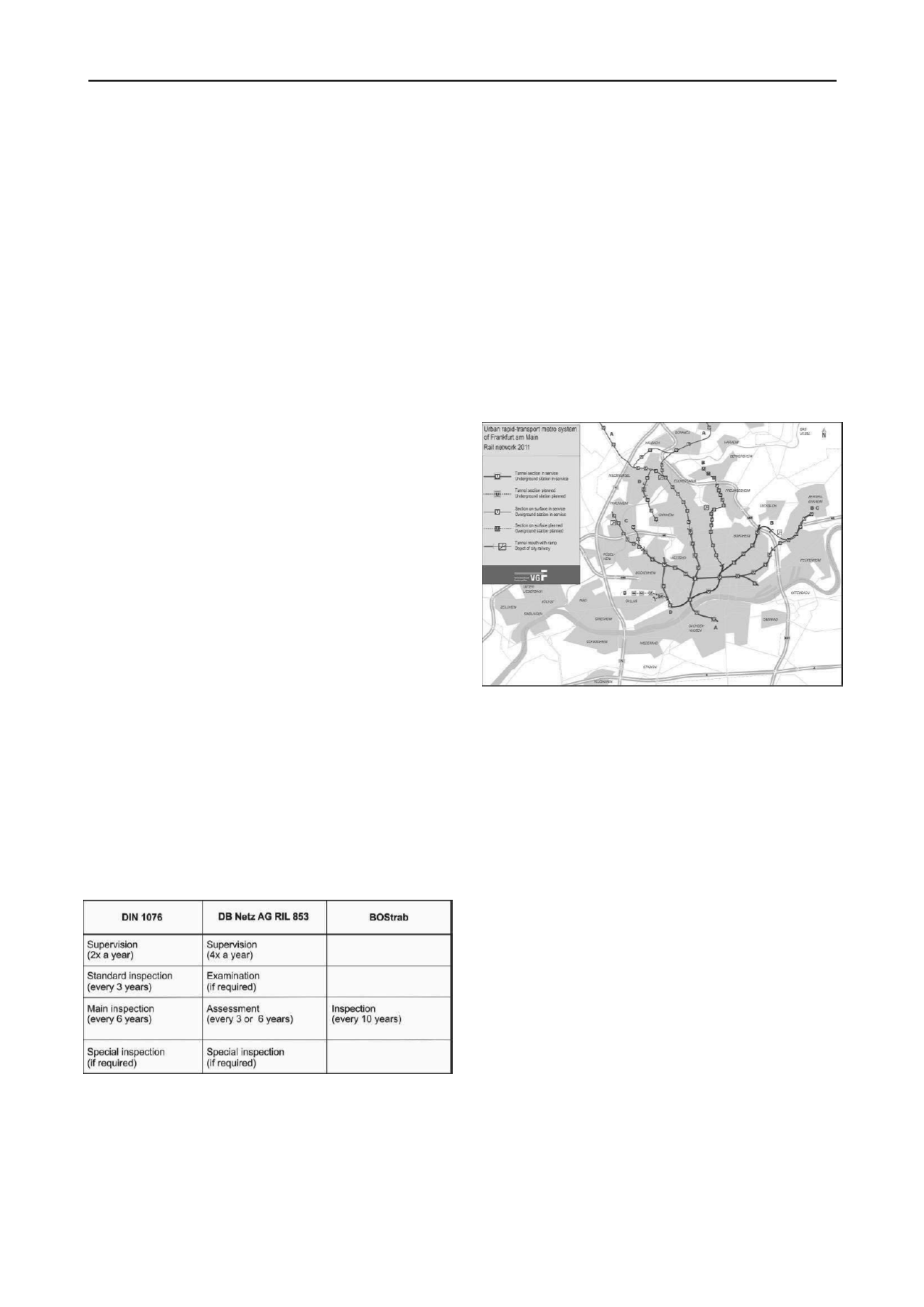

The terms, time periods and the scope of the engineering

inspection and supervision are different in the standards and

regulations mentioned above. For tunnels and underground

stations of urban metro systems the time periods and the scope

standards are defined in DIN 1076, BOStrab and RiL 853.

According to RiL 853 only an inspection every decade is

scheduled. Table 1 shows the different regulations.

Table 1. Engineering inspection and supervision.

2 ENGINEERING INSPECTION AND SUPERVISION

OF URBAN METRO SYSTEMS

The Institute and Laboratory of Geotechnics of Technische

Universität Darmstadt (TU Darmstadt) developed on behalf of

the operator of the public transport system of Frankfurt am

Main, the VGF, a new concept for engineering inspection and

supervision of the tunnels and underground stations of the urban

metro system.

The following boundary conditions are considered:

type of construction, size, number and age of the

underground structures

soil and groundwater conditions

practicability and economic efficiency of the modalities and

procedures of the engineering inspection and supervision

construction processes on the surface that have an influence

on the underground structures

Figure 2. Urban metro system of Frankfurt am Main.

The construction of the urban metro system of Frankfurt am

Main started in 1962. The underground structures were built

with the cut-and-cover method in open excavations or were

mined using the New Austrian Tunnel Construction Method or

tunnel boring machines. The tunnel sections have 2 tracks in 1

tube or 2 parallel tubes with 1 track each. The urban metro

system consists of 23 km of tunnels (1 resp. 2 tubes) and 26

underground stations. An extension consisting of 2 km of

tunnels and 4 new underground stations is planned. An

overview of the urban metro system is given in Figure 2.

Under consideration of the above mentioned boundary

conditions the following procedures of the engineering

inspection and supervision of the urban metro system of

Frankfurt am Main are planned:

standard inspection (E)

main inspection (H)

special inspection (S)

supervision (B), in the structures and on

surface

The system of engineering inspection and supervision is shown

in Figure 3 and defines the modalities and procedures for the

tunnels as well as for the underground stations.

The standard inspection (E) is a visual inspection done on the

traffic level of the structures every 3 years, but not in years

when a main inspection (H) is scheduled. The main inspection

(H) is an inspection close to the structure. For main inspection

(H) auxiliary devices like mobile racks are necessary. Main

inspections (H) are also carried out before the period of

warranty ends. Special inspections (S) are carried out after

incidents with a strong impact on the structure (e.g. accident,