1720

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

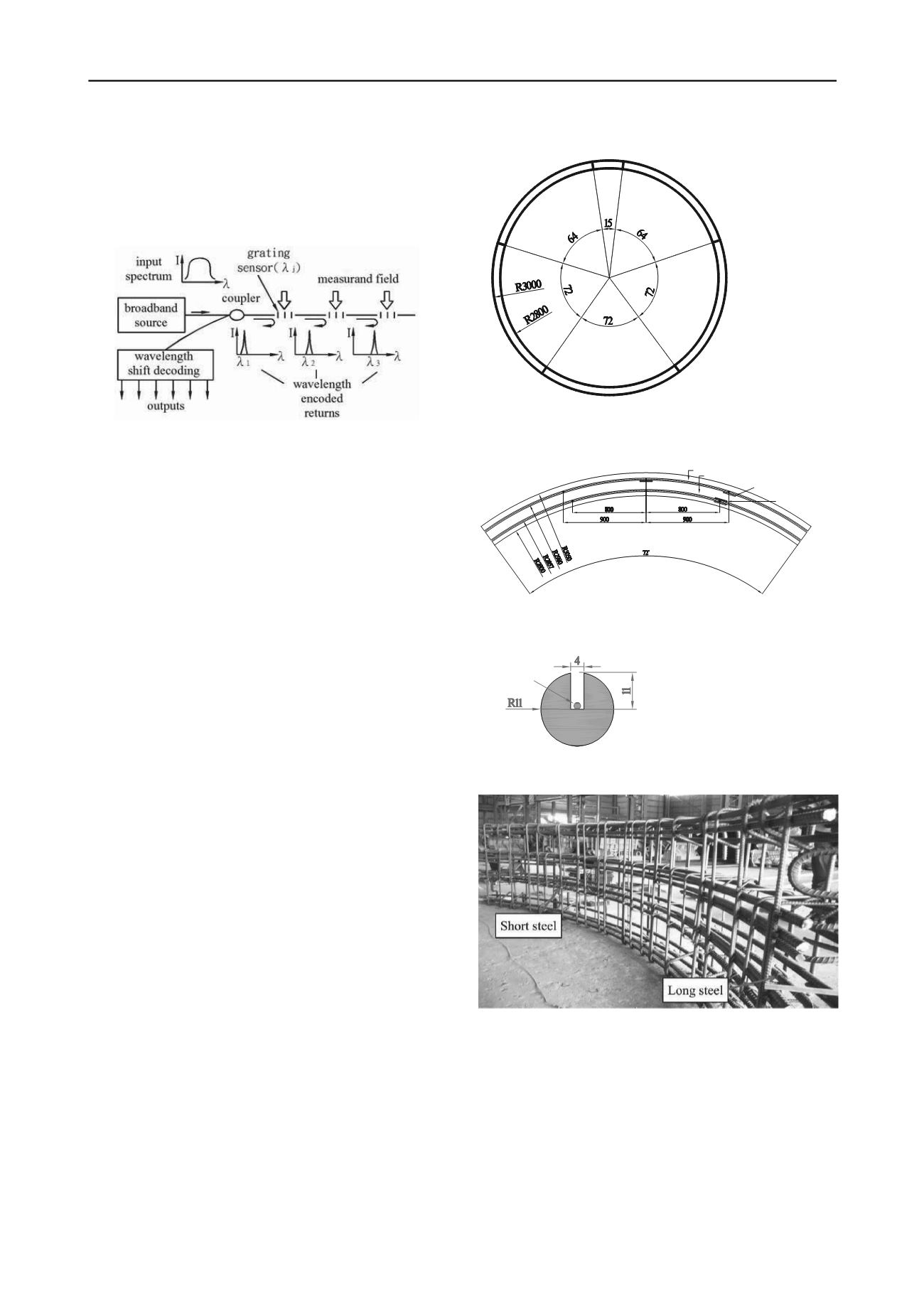

multiplexing among various sensors on a single fibre can be

accomplished by wavelength division addressing as

conceptually described in Figure 1. The FBG is partially

distributive because only those parts of the optical fibre with

FBG are used as strain sensors and these sensors can share the

same optical fibre transmission line.

Figure 1. Schematic diagram of Fibre Bragg Grating

(Kersey 1992), I = light intensity

wavelength.

The authors developed the techniques to install FBG strain

sensors on the tunnel lining panel reinforcement prior to

concrete casting. FBG strain readings could be recorded during

panel concrete curing, shipping, before and after field

installation for long term monitoring. The absolute strains

experienced by the lining panel could be determined according

to baseline readings taken before installation and data recorded

following the completion of the tunnel lining. The authors

developed the techniques of attaching FBG strain sensors and

other FBG based sensors to the reinforcement and/or the tunnel

lining panel. The techniques were first applied at Taipei MRT

Xinyi line, installation of the first FBG sensored shield tunnel

panel was completed on March 24, 2008. Continuous,

automated strain readings were recorded from January 1, 2010

to April 26, 2012. The paper describes the techniques of FBG

sensor installation, the case of applying this technique to Taipei

MRT Xinyi line, presents available records and discusses

implications in the design and safety monitoring of shield tunnel

linings.

2 FBG STRAIN SENSOR INSTALLATION AND PANEL

LOAD TEST

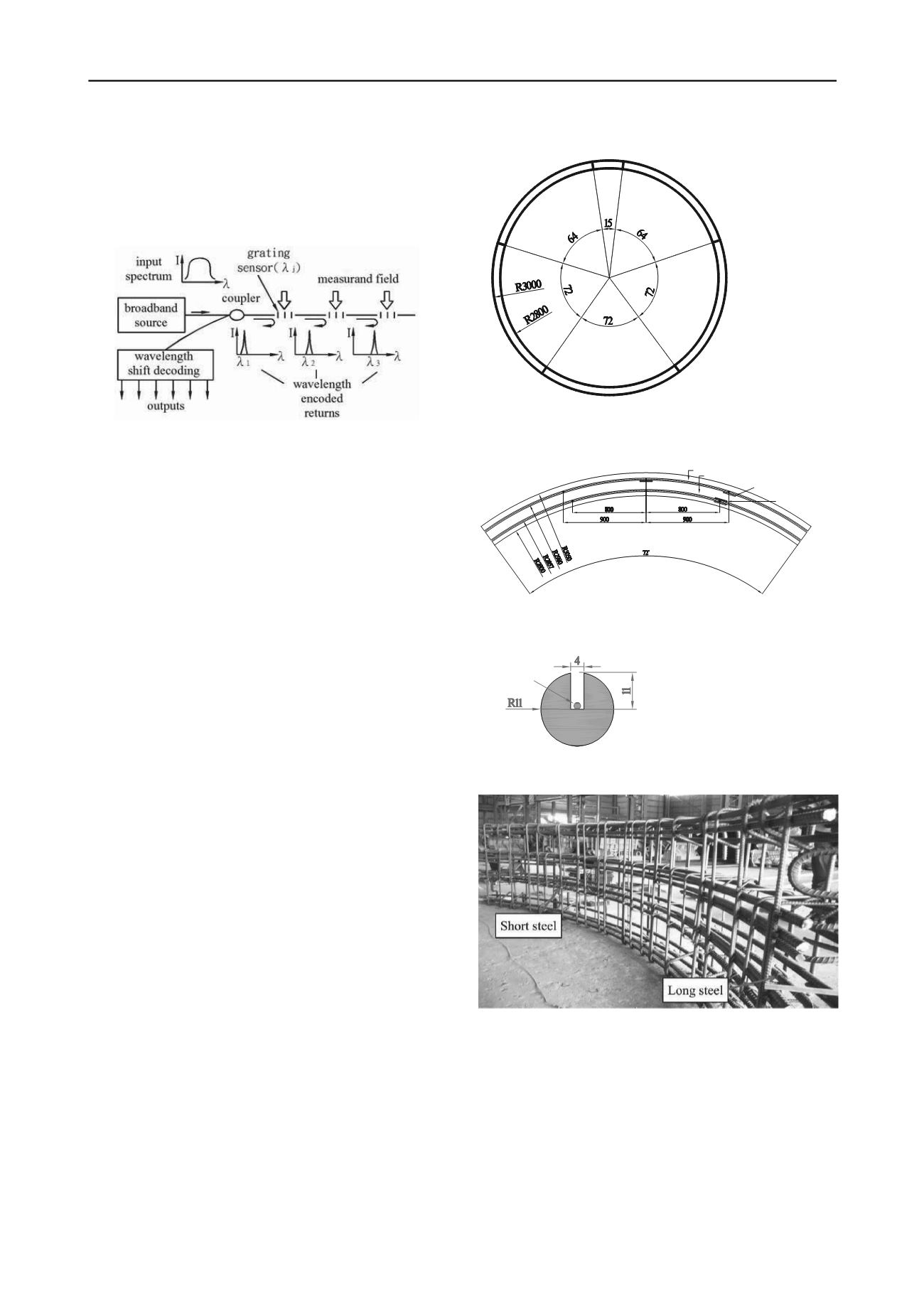

Figure 2 shows a typical cross section of the Taipei MRT Xinyi line

tunnel. It has an outside diameter of 6m and a thickness of 200mm. The

tunnel lining is fabricated by assembling six, 1m long pre-cast concrete

panels. The designations and the dimensions of these panels are shown

in Figure 2. For the case reported herein, FBG strain sensors were

installed in panels A1, A3 and B. For each panel, an inner (short) and an

outer (long), No. 7 reinforcement steel was selected for instrumentation.

Three FBG strain sensors were attached to the designated reinforcement

steel. The FBG’s on the long steel were numbered in the clockwise

direction while those on the short steel were numbered in the counter

clockwise direction. Figure 3 shows the locations and numbering the

FBG strain sensors for the case of A1 panel. An electrical thermo

couple and a vibrating wire (VW) strain gage were also installed as

shown in Figure 3 to provide reference values. A 4mm wide and 11mm

deep channel was milled into the reinforcement steel as schematically

shown in Figure 4. The optical fibre along with the FBG’s were

attached to the bottom of the channel. For strain measurement, the

FBG’s were epoxied to the surface of a well-polished and cleaned steel

surface. A separate FBG, designated as FBG (T) sealed inside a tubing,

so that it is not making contact with the steel, was placed next to

FBG2(L) and served as a temperature sensor. The empty space of the

channel was then filled with epoxy. This arrangement minimizes the

effects of local bending of steel on FBG strain readings and provides

good protection of the optical fibre during casting and handling of the

panel. Figure 5 shows a fully assembled reinforcement steel cage with

all FBG sensors included.

A1

A2

A3

C

K

B

Forward Direction

Unit : mm

¢X

¢X

¢X

¢X

¢X

¢X

Figure 2. Cross section of the Taipei MRT Xinyi line tunnel.

VW strain gauge

Long steel

short steel

FBG3(L)

FBG2(L)

FBG1(L)

FBG3(S)

FBG2(S)

FBG1(S)

Unit

:

mm

Thermo couple

Figure 3. Numbering of FBG strain sensors in A1 panel.

Optical fiber

Unit:mm

Figure 4. Placement of optical fiber in reinforcement steel.

Figure 5. A fully assembled reinforcement steel cage for A1 panel.

The precast concrete panels were manufactured in a factory. The

reinforcement steel cage along with low slump concrete were placed in

a steel mold and subjected to vibration. Upon initial setting and de-

molding, the panel was cured in a steam room and followed by

submerging under water for three days before taking out and undergo

the rest of the curing in the air. The effects of this harsh environment are

reflected in the sharp increase in the FBG wave length during steam

curing as shown in Figure 6. Every one pm (10

-12

m) wavelength change

corresponds to approximately 1

of strain. The continued readings

assure the integrity and functionality of the FBG’s during the curing

stage of the panel.