1713

Technical Committee 204 /

Comité technique 204

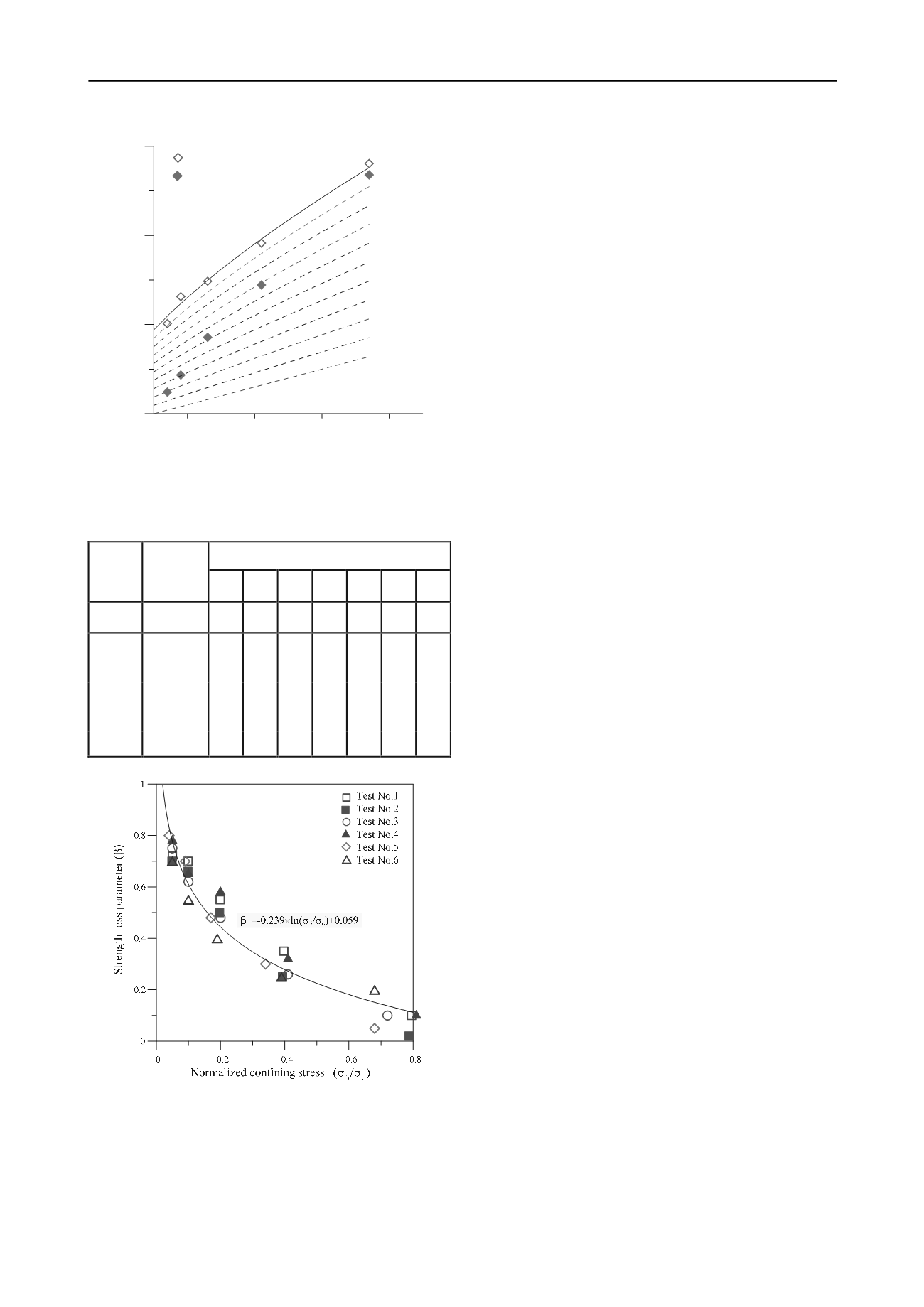

0

20

40

60

80

(MPa)

0

100

200

300

(MPa)

=0.0

=0.3

=0.5

=1.0

=0.1

=0.8

Peak strength

Residual strength

=0.2

=0.4

=0.6

=0.7

=0.9

Figure 3. Schematic evaluation of the stress loss parameter by using the

post-peak form of the Hoek-Brown failure for the Test No.1

marble specimen

Table 2. Results of post-peak strength estimation for the Test No.1

marble specimen (stress unit: MPa)

Mechanical parameters

Confining

stress

(

3

)

c

R

c

b

m

R

b

m

s

a

Peak

-

0 94

-

6.0

-

1.0 0.5

64

0.05

89

5.7 1.0 0.5

32

0.30

66

4.2 1.0 0.5

Post-peak

16

0.48

-

49

-

3.1 1.0 0.5

8

0.70

28

1.8 1.0 0.5

4

0.80

19

1.2 1.0 0.5

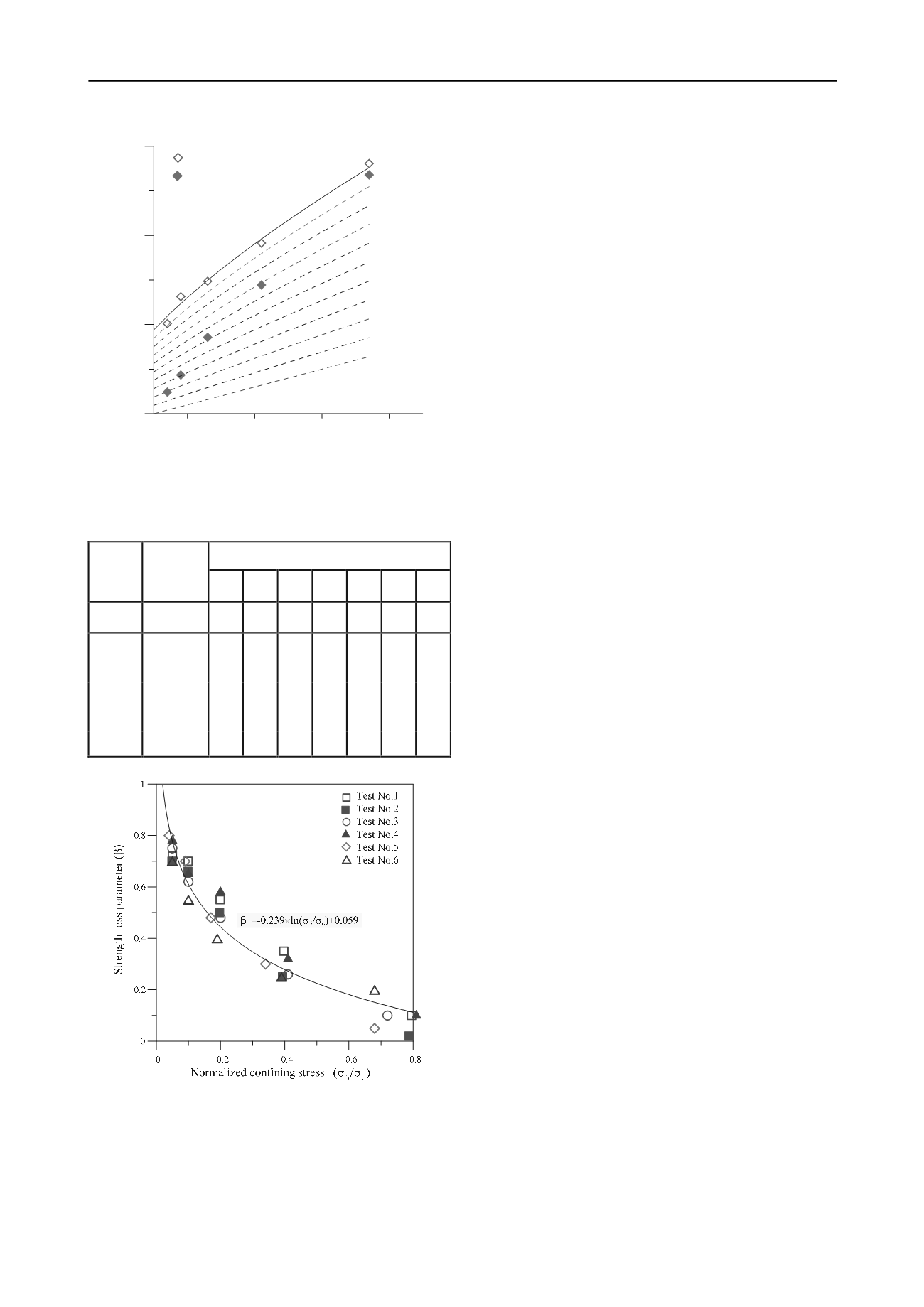

Figure 4. Correlation between strength loss parameter and normalized

confining stress on marble

Furthermore, the relationship between the strength loss

parameter and the normalized confining stress (divided by

uniaxial compressive stress) for the tests showed in Table 1 was

sketched (see Figure 4). From the figure, the strength loss

parameter is progressively increased with the decreasing of the

confining stress and the regression equation can be obtained as

059 .0 /

ln 239 .0

3

c

(5)

4 CASE STUDY

The effect of post-peak strength degradation on deep

underground excavation was examined by a modeling of a road

tunnel. The tunnel is part of the project providing a safe and

reliable connecting highway for east and north Taiwan. The

case tunnel is a twin-hole tunnel with excavation span of 12.5 m.

The pillar width between two tunnels is about 30 m. According

to the geotechnical survey report (Sinotech 2011), the main rock

type along the tunnel is marble, which average uniaxial

compressive strength is around 80 MPa. The strength

parameters of rock mass in good quality range (GSI=80) was

estimated by using the method suggested by Hoek (2002). The

estimation results of peak strength are listed in Table 3.

Furthermore, Equation 2, 3 and 5 was adopted to estimate the

post-peak strength under various confining stresses. The

computer program FLAC was used to simulate the tunnel

construction. A subroutine of FISH language embedded within

FLAC was developed to input the parameters of post-peak

strength depending on the value of confining stress as the

element is yielding during period of calculation.

The top heading method is designed for the tunnel

excavation and the cycle length is 3.5 m for good rock mass

(GSI=80). The support works used including 8 cm thick steel

fiber reinforced shotcrete with systematic rock bolts. The rock

bolts installed are of 25 mm

with length of 4 m and spaced of

2.0m

×

3.0~4.0m. The allowable tunnel deformation is 5 cm in

the support system. Two different overburden depths of 500 m

and 1000 m were considered in the case study. Vertical stress

(P

0

) was calculated by dead weight of rock mass as P

0

=

H,

where

is the unit weight of rock mass and H is the overburden

depth. The horizontal stress was estimated with references to the

results of in-situ overcoring test in the eastern Taiwan (Hsiao et

al. 2006). The maximum horizontal stress is 1.2 times of

vertical stress.

The Hoek-Brown model (no strength degradation, HB model)

and the post-peak strength degradation model (SD model) were

adopted to analyze the tunnel excavation behavior. The results

of the analyses are displayed in Table 4. When the overburden

depth is 500 m with the Hoek-Brown model, the roof settlement

of tunnel is 1.7 cm, the horizontal convergence of bench is 1.9

cm and both the relaxation zone thickness at the roof and the

sidewall are 0.5 m. Then the tunnel deformation would increase

apparently where the overburden reaches to 1000 m, that is, 3.8

cm in the roof settlement and 4.2 cm in the horizontal

convergence. And the relaxation zone thickness surrounding the

tunnel would increase to 1.5 m as well. However, the tunnel

deformation is still under the designed allowable value of 5 cm

even the tunnel depth reaches to 1000 m.

In case the post-peak strength degradation is considered, the

roof settlement of 3.7 cm and the horizontal convergence of

bench of 4.4 cm are obtained at the tunnel depth of 500 m in the

SD model. And approximate 2.6 times of deformation increased

would occur when the tunnel depth reaches to 1000 m, that is,

9.8 cm in roof settlement and 9.0 cm in horizontal convergence.

The tunnel deformation obviously exceeds the designed

allowable value and tunnel may need re-mining in deep

overburden condition, as shown in Figure 5.

The above analyses demonstrate that the characteristic of

post-peak strength degradation may affect the tunnel behavior.

The effect intensity is progressively significant with increasing

tunnel depth, as illustrated in Figure 5. There is an outstanding

increase in tunnel deformation at the depth of 1000 m for the

SD model. In case additional reinforcement or modified

excavation measure is not adopted, severe tunnel deformation

may endanger tunnel stability. The strength degradation of

marble beyond brittle failure plays an important role in the

stability of deep tunneling.