1708

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

carbonate components was found in medium-grained oolitic

limestone with maximum values of 8%, which is mostly given

by quartz and subordinately by feldspar.

3 METHODS

3.1

Sampling, core drilling and laboratory analyses

Samples were obtained from underground structures and surface

quarries. Additionally where it was avilable core drillings were

made.

For the laboratory analyses samples were drilled and cut

from porous limestone blocks or core drillings were processed.

Cylindrical test specimens were used and the following rock

mechanical tests were made according to European Norms: bulk

and material density (EN 1936), ultrasonic pulse velocity (EN

14579), water absorption (EN 13755) uniaxial compressive

strength (EN 1926), indirect tensile strength.

3.2

Numerical modelling

Different FEM codes were use to modell the cellars cut into

porous limestone such as Plaxis v8, Geo4 Tunnel module,

Phase2, Examine3D.

The first three codes use the same calculation methods but

they are able to use different material models. The Plaxis v8 and

the Geo4 are developed for modeling soils while the Phase

2

is

for modeling rocky environment. In spite of it the Plaxis and

Geo4 can be also used for rocks but the Phase

2

has some

specific material model for rock masses for example the Hoek-

Brown model, and it is able to calculate with the anisotropy of

the rock masses.

The porous limestone can be described as soft rock or hard

soil, therefore all of these codes can be used for modeling its

behaviour. The rock mass of the porous limestone is usually can

be considered as intact rock or blocky according to the chart of

Marinos & Hoek (2000). The joint system of the limestone is

characterized by faults or bedding. The Phase

2

has a good tool

for modeling the joints.

The geometry of the cellars sometimes very different, in the

area of Budapest can be found individual cellars, but sometimes

huge cellar systems as well. The cross-sectional area of them is

varies from 2 m

2

to more than 100 m

2

and there are cellar

systems which is above each other. The modeling of a cellar

system with such complicated geometry is not easy, sometimes

it is necessary to use 3D tools for example Examine3D. This

software is easy to use, but it is not able to consider different

layers and joints.

4 RESULTS

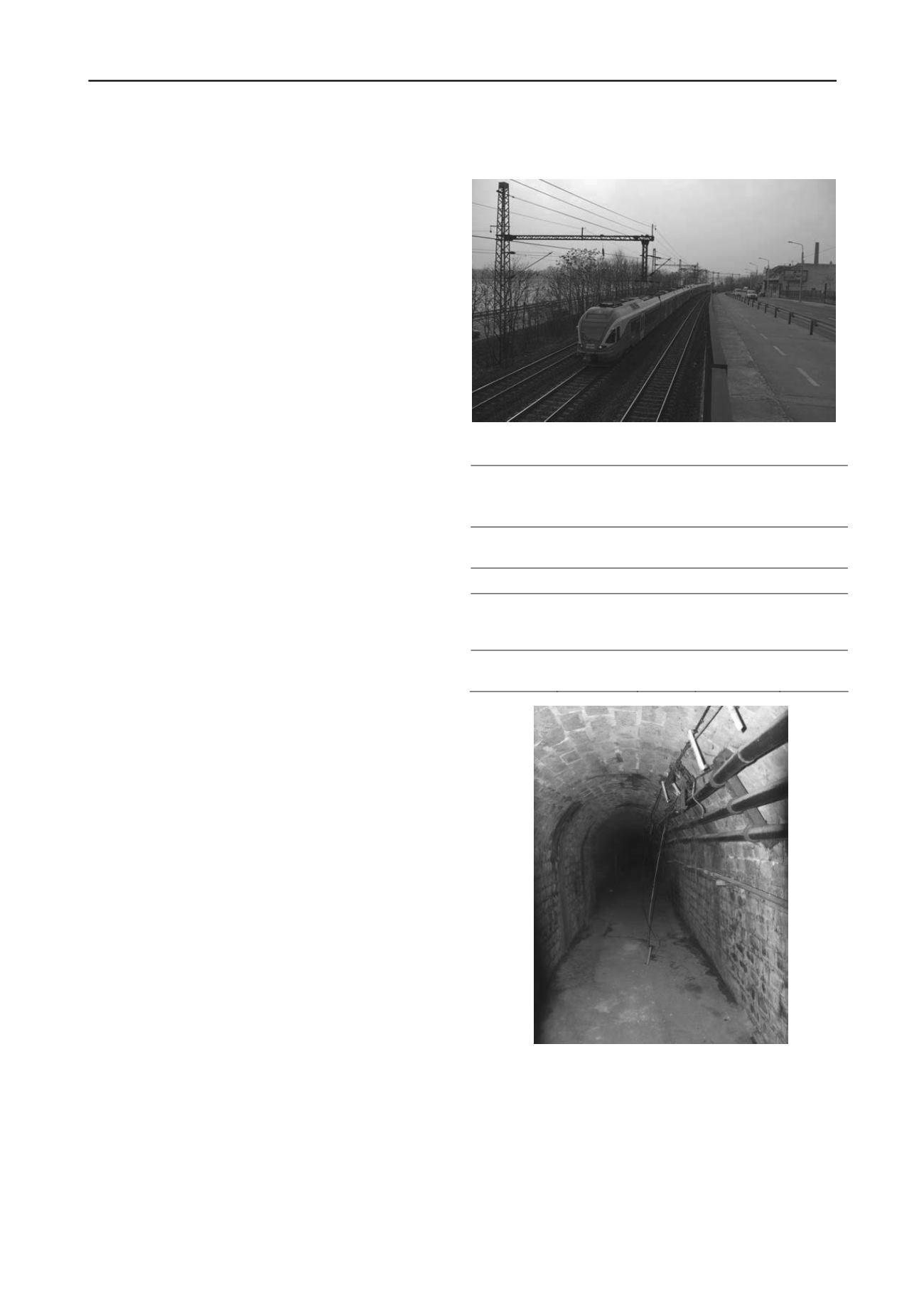

The paper provides three different cases on cellar system cut

into porous limestone. The first one is a more than a hunderd

years old individual cellar that was cut under a road and a

railway (Fig.1). There is a plan to enlarge the cross-section to

use the system as an access footpath to a huge cellar system.

The small cover above the tunnel is the major risk.

The second case is the study of the interaction of two cellar

systems, which are above each other.

The third case study deals with a cellar that is located just 3

metres below the surface. According to plans a new house is to

be built above.

4.1

Tunnel enlargement

The area of the first and the second case study is located very

close to each other, namely the planed tunnel goes into the

cellar system of the second case. Thus the differences between

them are the vertical placements of the cellars. The base level of

the tunnel is at 102.8 m Asl., while the base level of the second

one is about 106.5 m Asl. The geological set-up of the area of

the tunnel is showed in the table 1.

Figure 1. The road and the railway above the tunnel

Table 1. Layers and its parameters used for modeling

Layer

bulk density

(kg/m

3

)

friction

angle

(degree)

cohesion

(kPa)

rock mass

modulus

(MPa)

sandy clay

fill

1800

25

0

5

clayey rubble

1950

18

40

8

porous

limestone

rubble

1650

47

17

80

porous

limestone

1650

49

174

248

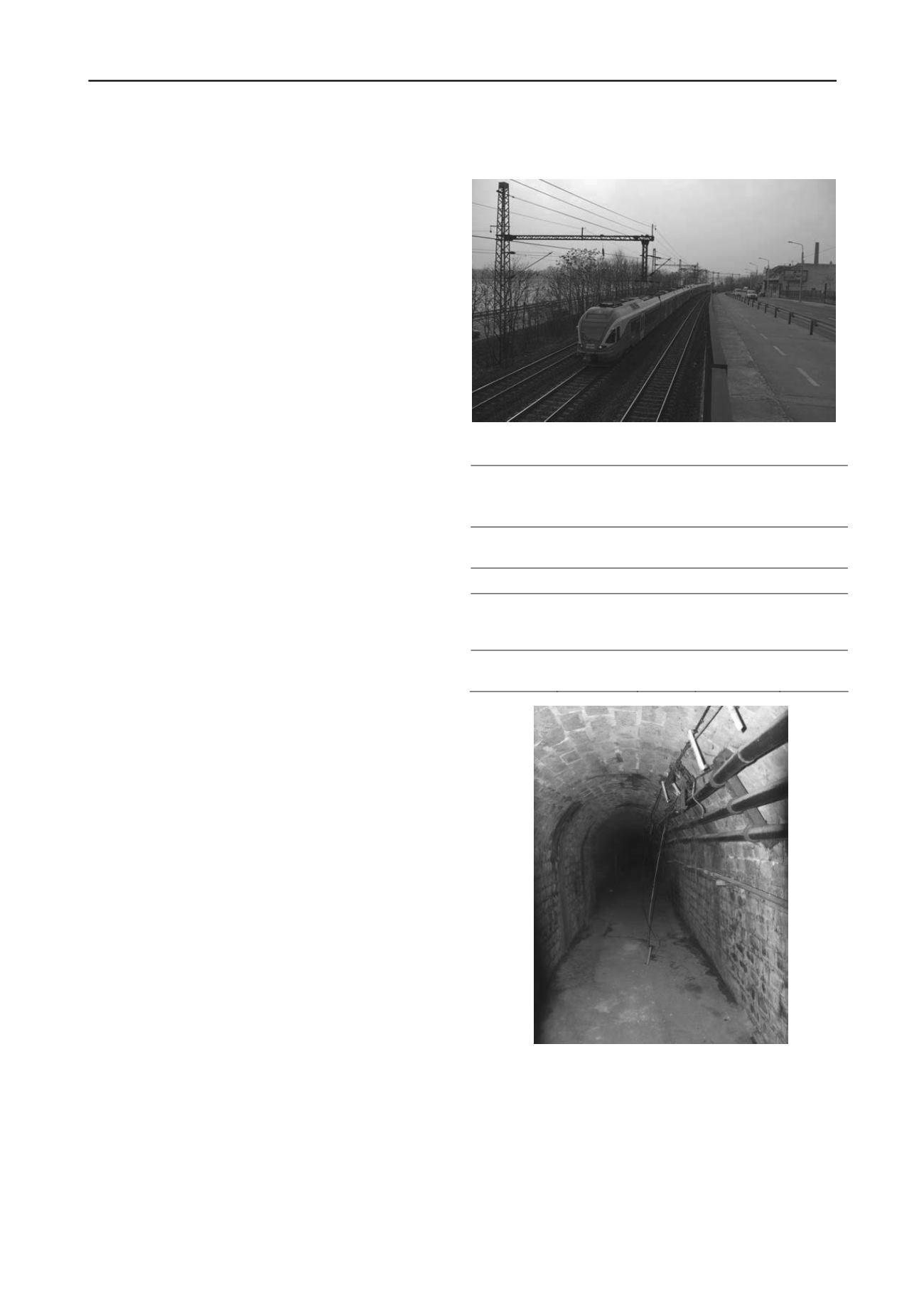

Figure 2. The tunnel with the concrete masonry support system

The cover of the tunnel is 1.3 m, and it has a concrete

masonry linning system (Fig.2).

Above the tunnel the clayey rubble layer is found, and

behind the tunnel lining the porous limestone rubble, while the

intact porous limestone only occurs under the base level of the

tunnel. The enlargement of it can be built by reducing the base

level of the tunnel. According to the drilling results behind the

concrete block masonry the void between the porous limestone

blocks are very high. Therefore the rock mass behind the