1698

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

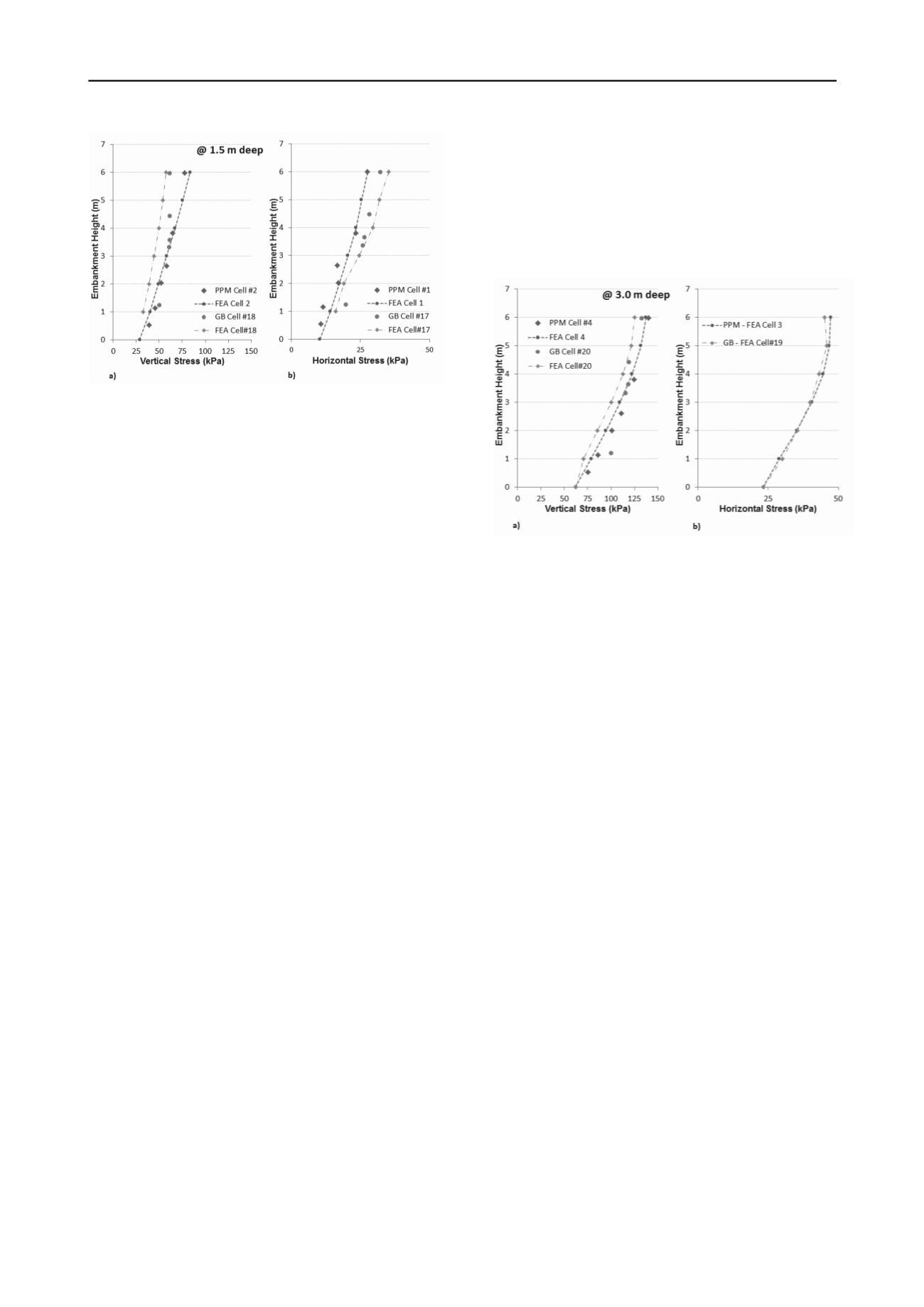

Figure 4. Compression of the FEA results with the vertical and

horizontal stresses data obtained from the field test at 1.5 m depth.

4.2

Stresses Measured at the Bottom of the Trench (3 m)

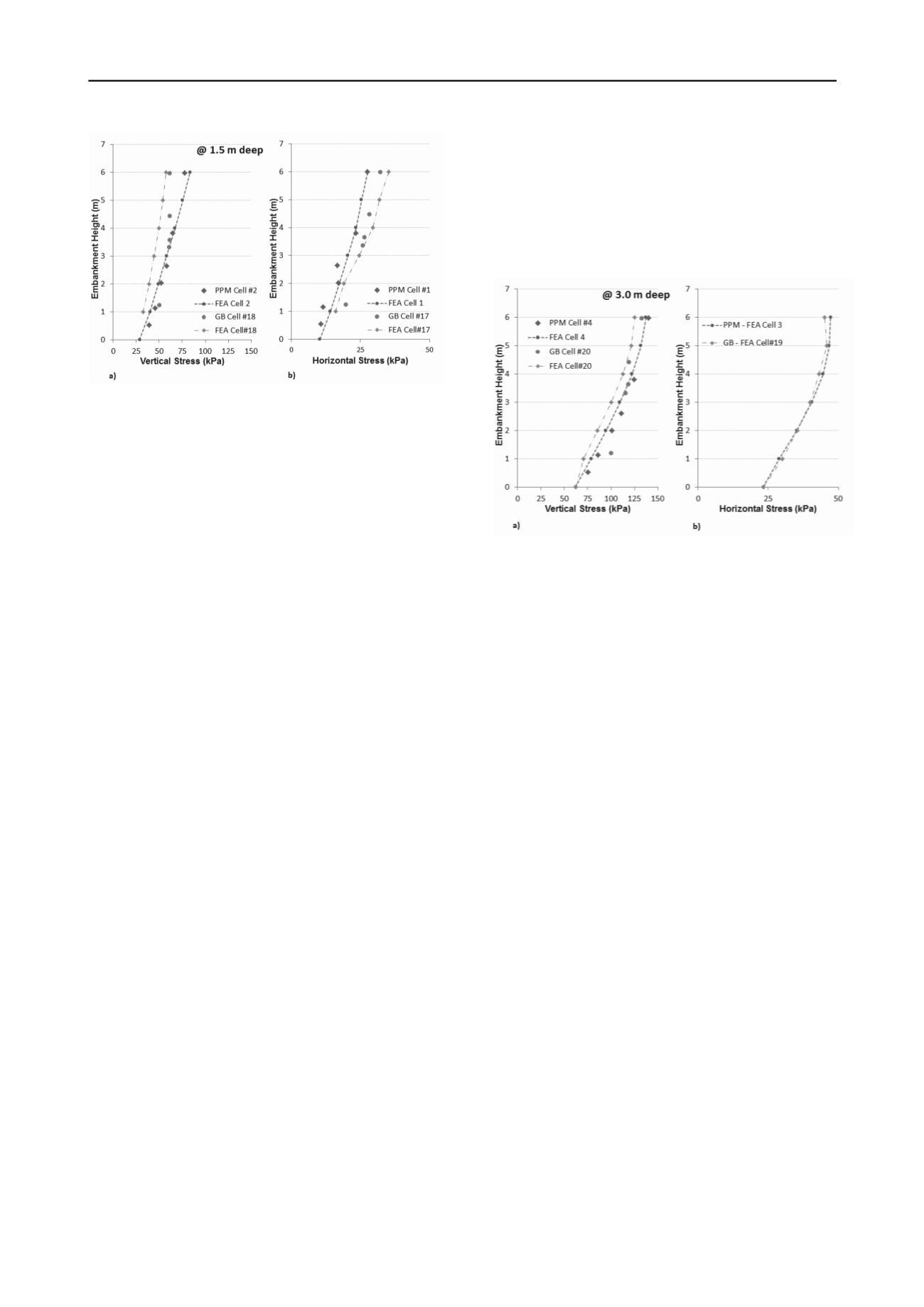

Figure 5 shows the variation of the vertical stresses that were

measured at 3.0 m depth in the trench (cells 4 for the PPM and

20 for the GB) and its comparison to the stresses predicted by

the FE analyses. Pressure Cells #3 and 19 that measures the

horizontal stresses were damaged during construction, thus

Figure 5b shows only the results of the FEA for these cells. The

stresses at this depth are also complex since their magnitude is

influenced not only by the installation method (i.e. the existence

of the 3 m wide crib in GB) but also the stress arching caused

by the lightly compacted surrounding above this location. The

measured and calculated stresses show a reasonable agreement

at this depth as well.

The results shown in Figure 5a indicate that the measured

vertical stresses increased as the embankment height was

increased. This increase ranges from 78 kPa to 140 kPa for PPM

installation and from 70 kPa to 125 kPa for the GB installation

for embankment heights of 1m and 6 m, respectively. The

results indicate that 11% reduction in vertical stresses is

achieved by the use of GB installation when the full

embankment height was achieved.

The results shown in Figure 5b indicate that the increased

embankment height increased the horizontal stresses from 23

kPa to 47 kPa for PPM installation. It should also be noted that

the difference between the horizontal stresses occurred at PPM

and GB cases was not as pronounced at this depth, possibly due

to the higher stiffness of well compacted granular surround and

as the depth increase the arching effect due to the 3 m wide

geogrid bridging softens.

5 SUMMARY AND CONCLUSION

A full scale instrumented test embankment was constructed by

Ontario Ministry of Transportation to study the effects of

embankment construction on the existing underground utilities.

The test embankment comprised four sections which facilitated

the evaluation of four configurations including the conventional

backfill, induced trenching and two at-grade geogrid reinforcing

bridging with different spans. Each configuration consisted of a

3 m deep trench underneath a 10 m wide, 10 m long and 6 m

high embankment section. The earth pressure cells were

installed to monitor stresses at the fill/ground interface and at

the depths of 1.5 m and 3 m. A numerical model of the full scale

instrumented test embankment was developed using the finite

element program PLAXIS. Both measured and estimated

material properties were utilized in the numerical analyses to

reproduce the trends of changes in stresses as a result of

installation methods. This paper presents the results of stress

measurements in a utility trench overlain by an embankment.

The measurements that were obtained both during and after

construction of a full-scale test embankment and results of

numerical modeling that helped clarify mechanisms of stress

reduction were presented. The performed analyses showed that

geogrid bridging has potential to reduce the stresses on buried

infrastructures at shallow depths; however, the magnitude of

reduction reduces with depth as the arching effect decreases.

Figure 5. Compression of the FEA results with the vertical and

horizontal stresses data obtained from the field test at 3.0 m depth.

6 ACKNOWLEDGEMENTS

The authors acknowledge and the financial support provided by

the New Brunswick Innovation Foundation (NBIF), and the

support provided by the Ontario Ministry of Transportation,

Material Engineering and Research Office.

7 REFERENCES

AASHTO "AASHTO LRFD Bridge Design Specifications", American

Association of State Highway and Transportation Officials,

Washington, 2007.

CHBDC,"Canadian Highway Bridge Design Code", Canadian

Standards Association, Rexdale, Ontario, 2006.

Haas, R.,Walls, J. and Carroll, R.G., 1988, “Geogrid Reinforcement of

Granular Bases in Flexible Pavements”, Transportation Research

Record 1188, pp. 19-27.

Love, J.P., 1984. Model testing of geogrids in unpaved roads.

Dissertation (Doctoral). University of Oxford, Oxford, UK.

OPSS 314 (1993), “Construction Specification for Untreated

Granular, Subbase, Base, Surface Shoulder and Stockpiling”,

Ontario Provincial Standard Specification.

PLAXIS BV (2011). Reference Manual PLAXIS BV: Amsterdam, the

Netherlands.