1697

Technical Committee 204 /

Comité technique 204

3 NUMERICAL MODEL

In order to investigate the stress reduction mechanism of

geogrid bridging, finite element analyses (FEA) were carried

out using the software package Plaxis 2D (Plaxis bv. 2011).

Two sets of numerical models were developed to analyze

stresses generated in cases of PPM installation (Section 1) and

the 3 m wide at-grade geogrid bridging, GB (Section 4)

installation. An elastic-plastic soil model with Mohr-Coulomb

failure criterion is used during the simulation of full scale field

test due to the simplicity of the model and availability of model

parameters.

The strength parameters were determined and reported in a

geotechnical investigation and design report prior to the

construction of test embankment. However, no direct

determination for the stiffness properties of soil was performed.

Thus, elastic moduli for various soils were determined based on

experience and calibrated against the deformation of

embankment. The stresses within the trench were affected by

the stiffness of the granular fill. Thus, the hyperbolic hardening

soil model from the Plaxis’ library was used to model the stress

dependent variation of stiffness of the fill materials within the

trench. A fully fixed boundary condition was applied at the base

of the models. The lateral boundaries of the models were placed

such that a distance equal to five times of embankment width

was maintained between the toe of the embankment and the

external boundaries of the soil domain, which is assumed to be

free in vertical direction and fixed in horizontal direction. The

subsurface conditions were determined using three boreholes

drilled within the footprint of embankment. The soil

stratigraphy comprises clayey-silt-till/silty-clay-till from ground

surface to a depth of 10 m (Layer 1). The Layer 1 is underlain

by a layer of silt/silty-clay layer to a depth of 20 m (Layer 2).

The embankment was constructed using native clayey silt-

till/silty-clay-till material. Table 1 summarizes the mechanical

properties of foundation soils, embankment fill and the

materials that comprise the trench fill.

4 RESULTS AND DISCUSSION

The results of the field test are presented here along with the

results of the FE analyses performed to investigate the trends of

stress variations measured during the field tests using the

estimated soil properties. The accuracy of the numerical

analyses is subjected to realistic material property assumptions.

The comparisons of the measured and calculated stresses for

PPM and GB installations show that despite local differences in

the magnitudes of stresses, the similar trends of stresses are

captured using the material properties outlined in Table 1. The

complex geometry of embankment-trench system and the use of

material with different stiffness values around the load cells

make the stress regime within the trench very complex both in

field test and numerical analyses. Thus, the main objective was

to show the influence of the geogrid bridging on the stresses

occurring in a trench, rather than presenting an exact stress

values that may occur in a conduit installation.

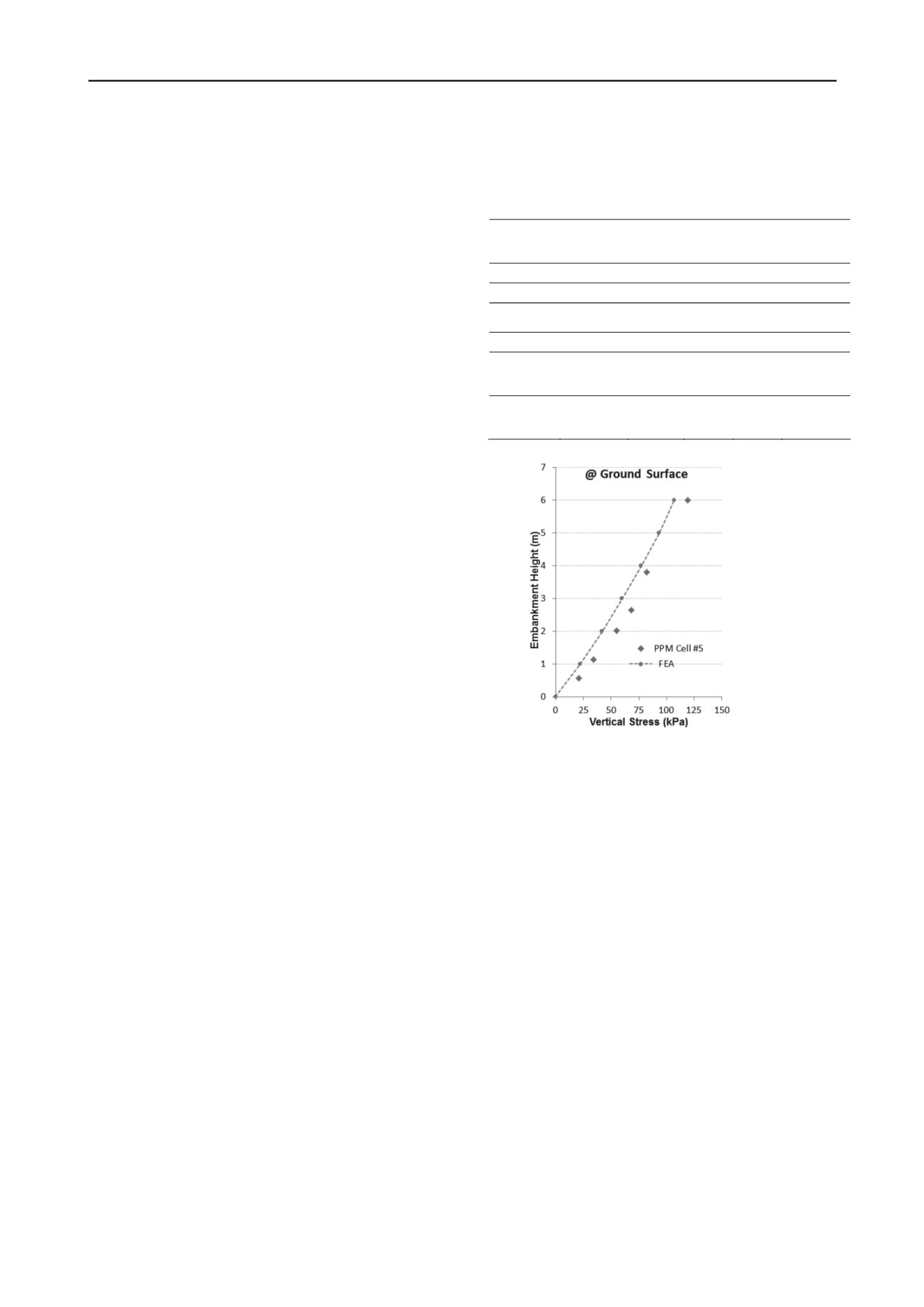

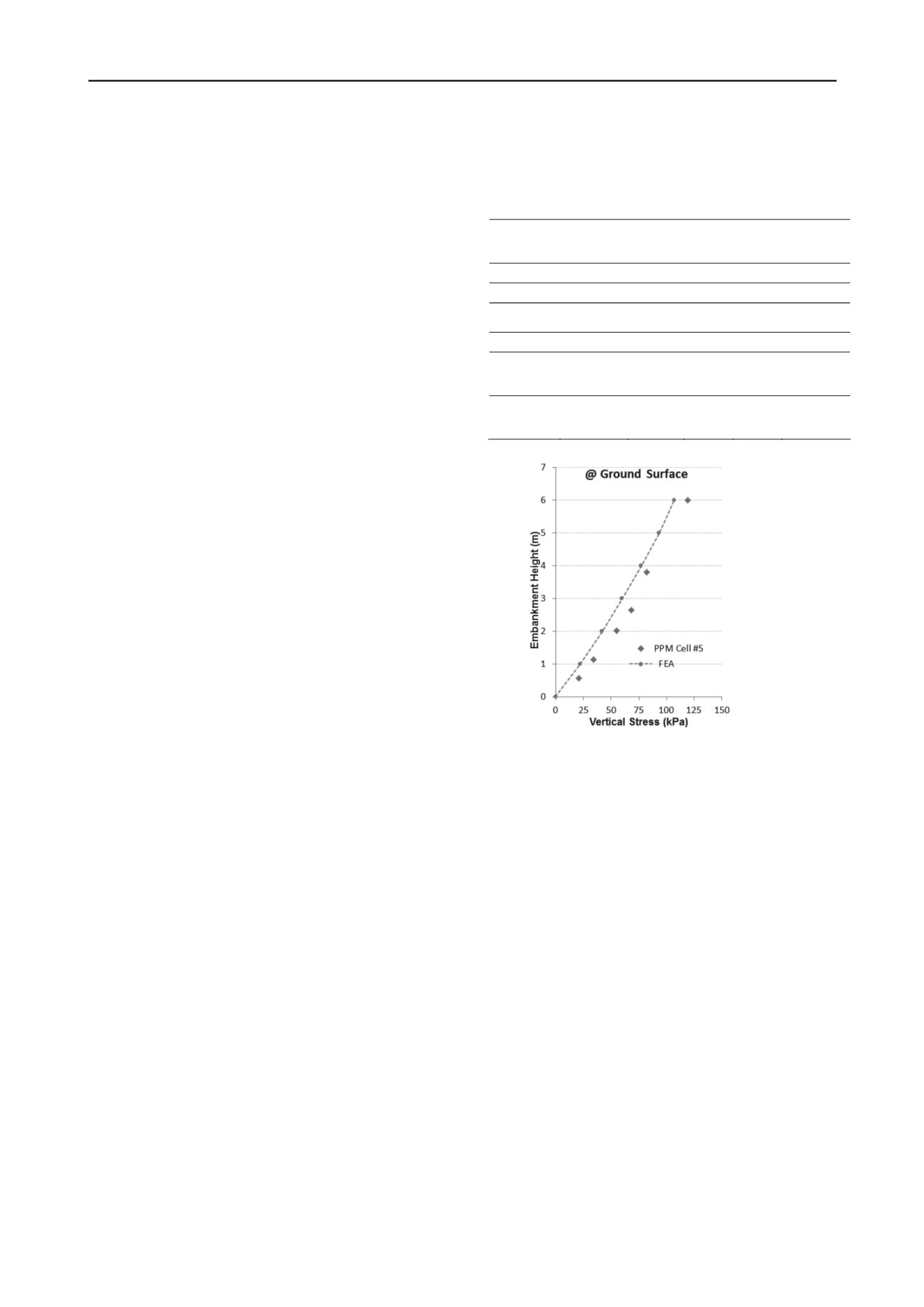

Figure 3 shows the variation of vertical stresses measured at the

foundation-embankment interface (cell 5) with the embankment

height. As it can be seen from Figure 3, the vertical stresses

show a typical increase that is almost linearly proportional to

depth of embankment.

4.1

Stresses Measured at Mid-height of the Trench (1.5 m)

Figure 4 shows the variation of the vertical and horizontal

stresses that were measured at 1.5 m depth in the trench (cells

1and 2, vertical and horizontal pressure cells for PPM; and cells

17 and 18, vertical and horizontal pressure cells for GB) and its

comparison to the stresses predicted by the FE analyses.

Table1. The parameters used in the FEA.

* unit weight varies with depth

+ in HSM m=0.5 and E

ur

= 3E

50

Figure 3. Compression of the FEA results with the vertical stress data

obtained from the field test at the foundation-embankment interface.

The results indicate that there is a reasonable agreement

between measured and calculated vertical and horizontal

stresses. The results shown in Figure 4a indicate that the vertical

stresses increased as the embankment height was increased.

This increase ranges from 45 kPa to 76 kPa for PPM installation

and from 45 kPa to 60 kPa for GB installation for embankment

heights of 1m and 6 m, respectively. The results indicate that

22% reduction in vertical stresses was achieved by the use of

GB installation when the full embankment height is reached.

The horizontal stress showed an inverse trend. The results

shown in Figure 4b indicate that the increased embankment

height increased the horizontal stresses from 11 kPa to 29 kPa

for PPM installation and from 18 kPa to 33 kPa for GB

installation. The results indicate that the use of GB installation

increased the horizontal stresses relative to those generated by

PPM installation. This increase was as high as 60% at the start

of embankment construction. However, the difference

weakened as the embankment height increased.

The results also show that both vertical and horizontal stresses

measured/calculated at the 1.5 m depth are substantially lower

than the values one would practically approximate using the

depth of overburden and the unit weigh of material. Such

reduction is caused by lightly compacted uniform granular

surrounding, which has a substantially lower stiffness that

reduced the magnitude of both vertical and horizontal stresses.

Constitutive

Modeling

Unit

Weight

(kN/m

3

)

Modulus

of

Elasticity

E

oed

(MPa)

Angle of

internal

friction

Layer 1

MC

22

130

-

40

Layer 2

MC

22

160

-

42

Embankmen

t Fill

MC

20-22*

95

-

33

Trench Fill

HSM

+

20

130 130

36

Lightly

compacted

surrounding

HSM

+

18

20

20

33

Well

compacted

surrounding

HSM

+

22

120 120

35