1696

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

and to gain an understanding of the stress reduction mechanism.

This paper presents the results of stress measurements inside the

trench protected using at-grade geogrid bridging as well as the

results of numerical model that helped clarify mechanisms of

stress reduction. The material presented in this paper is

considered to be of interest to researches and engineers.

2 METHODOLOGY

2.1

Description of the field test

An instrumented test embankment is constructed by Ontario

Ministry of Transportation over a 3 m deep trench to study the

effects of embankment construction on the underground

utilities. The test embankment is constructed as part of Highway

407 contract and is located near the Highway 407 and Weston

Road in Vaughan, Ontario. The test embankment comprised

several sections which facilitated the evaluation of four different

configurations including the positive projection installation,

induced trench installation and at-grade geogrid reinforcing

bridging. Since the objective of the testing program was to

evaluate the stresses reductions achieved by each of the

considered installation techniques, no actual culverts were

installed. Instead, the earth pressure cells were placed in

granular protective surrounds located at two different depths in

the trench. The first section is constructed as a conventional

control section (Section 1), which included an instrumented

trench that was conventionally backfilled with granular material

up to the grade level (Positive Projection Method). The second

section represents an Induced Trench Method installation (ITM)

(Section 2), which included an instrumented trench that was

backfilled with granular material that is overlain by a layer of

compressible Styrofoam chips up to the grade level. The third

and fourth sections include geogrid void bridges installed on the

instrumented trenches with different trench widths. The

evaluation of the induced trench method installation section was

performed as part of a separate study and is beyond the scope of

the present work. This study involve the results of the PPM

represented in Section 1 (the control case) and the 3 m wide at-

grade geogrid bridging, GB (Section 4). The following is a

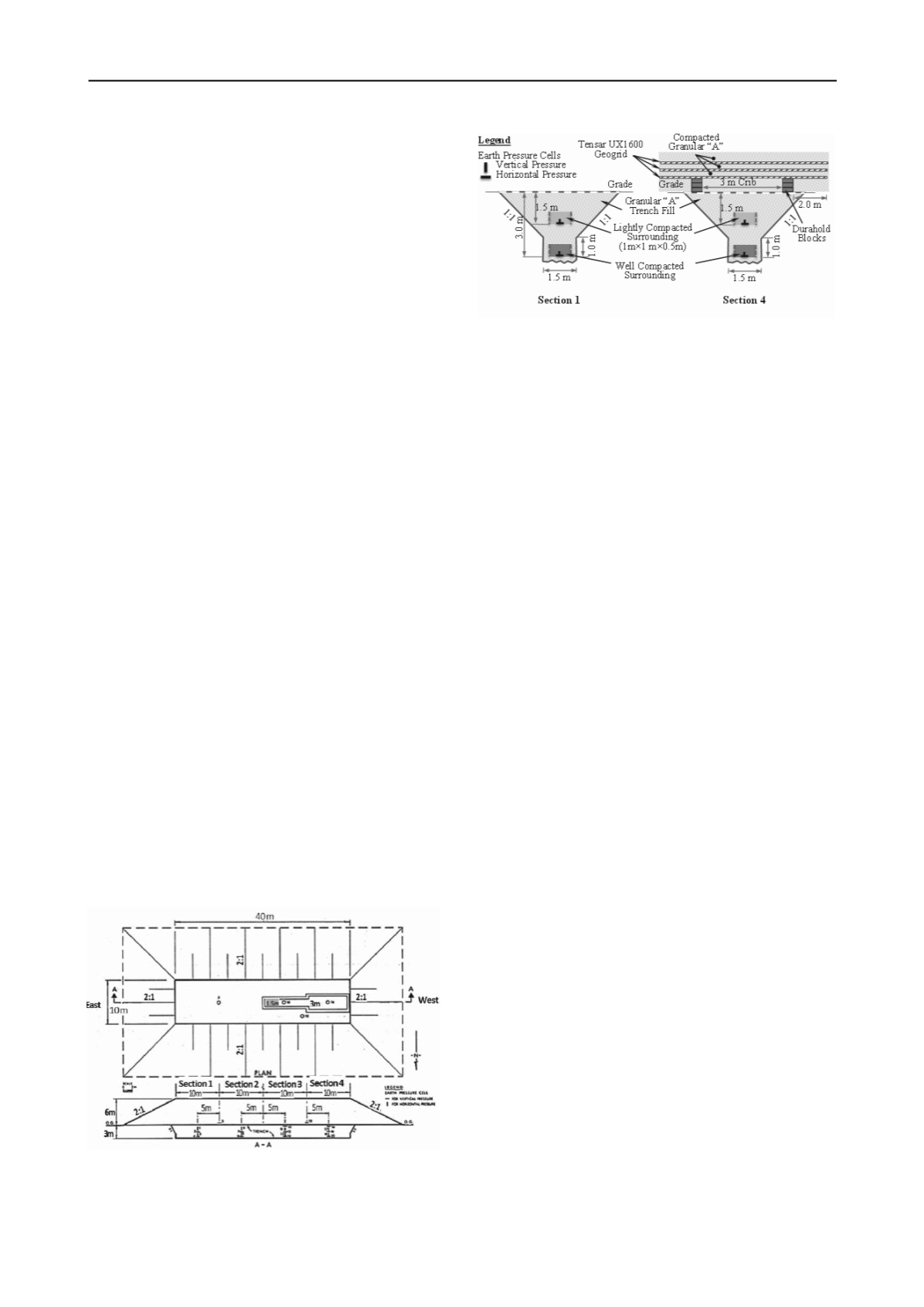

general description of field tests. The layout of test embankment

is depicted in Figure 1. The considered test configuration

comprises a 3 m deep trench backfilled up to the grade level

which underlies an embankment with the footprint dimension of

64m x 34m in length and width and with a height of 6 m. The

slopes of the embankment were constructed with a 2H:1V

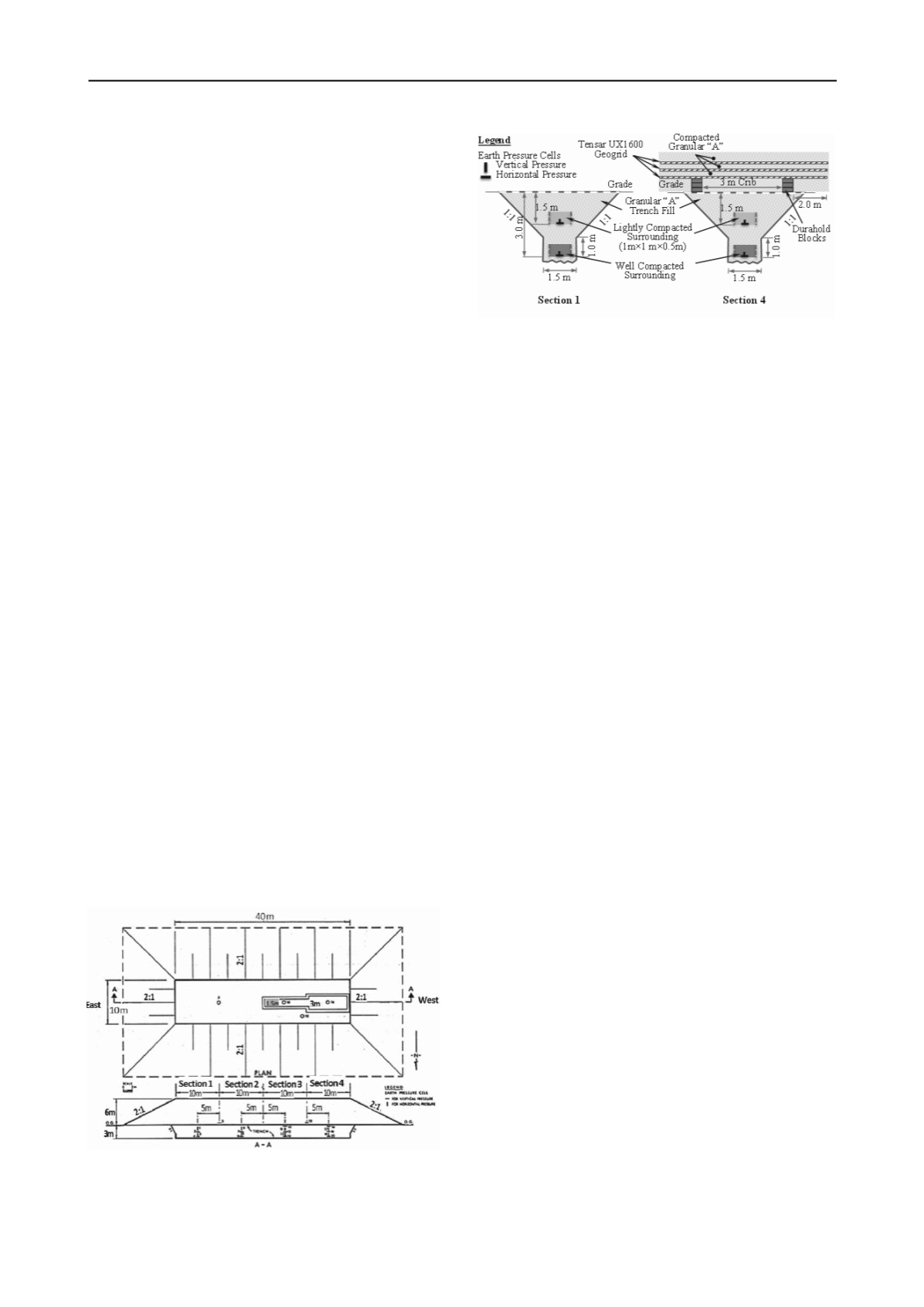

inclination. Figure 2a and 2b show the details of instrumented

trenches for Section 1 and 4, respectively.

Figure 1. Plan and Profile of Test Embankment

Figure 2. Details of the instrumented trenches

2.2

Construction and Instrumentation

The site was leveled and topsoil was removed prior to the

construction of the test embankment. A 1.5 m wide trench was

excavated to a depth of 3m. 1m above the bottom of trench,

trench slopes were cut to 1H:1V to maintain the integrity of

trench side slopes during the construction (see Figure 2). Two

drainage sumps are installed at each end to maintain a dry

condition in the trench. The base of the trench is filled with a

300mm thick compacted granular pad comprising Granular-A

(OPSS 314). Then, the installation of earth pressure cells was

initiated. Earth pressure cells with vibrating wire pressure

transducers were used. The earth pressure transducers were

placed at the bottom (3m from the grade) and the mid-height

(1.5 m from grade) of the trench with horizontal and vertical

orientations in order to allow measurement of vertical and

horizontal pressures, respectively. The pressure transducers

were placed in a 0.5m x 1m x 1m granular protective surrounds.

The granular surrounds were constructed as lightly compacted

at mid-height pressure cell and well compacted at the bottom

pressure cell to see the effect of the surround compaction on the

measured stresses. The protective surrounds, which were

constructed to eliminate a possible damage to pressure cells

were constructed using steel separators in four sides. The steel

separators separate the lightly compacted and well compacted

granular surrounds from compacted Granular-A, which

constitutes the rest of the fill material in the trench. The steel

separators were removed as the level of granular surrounds

reached 0.5 m height. A total of 2 transducer couples (vertical

and horizontal) were installed at the bottom and mid-height of

each trench for each section and an additional transducer is

installed at the interface between trench backfill and

embankment. The trench backfill encapsulating granular

surrounds, comprise Granular A compacted to 95% of Standard

Proctor Dry Density. The pneumatic lines were extended

through a PVC pipe, which followed the edges of trench and

connected to a monitoring station.

The embankment was constructed using native cohesive soils in

the area. The soil was placed in the lift of 300mm and

compacted to 95% of Standard Proctor Dry Density. The

portion of the embankment fill immediately above the trench

was placed by hand and compacted by self-propelled

compaction equipment (Bomag BW65S) in order to protect

against heavy machine loading used for compaction of

embankment fill. The embankment fill, including the zone

above the trench, is compacted using regular compaction

equipment after fill height reached 1.3 m.