1700

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

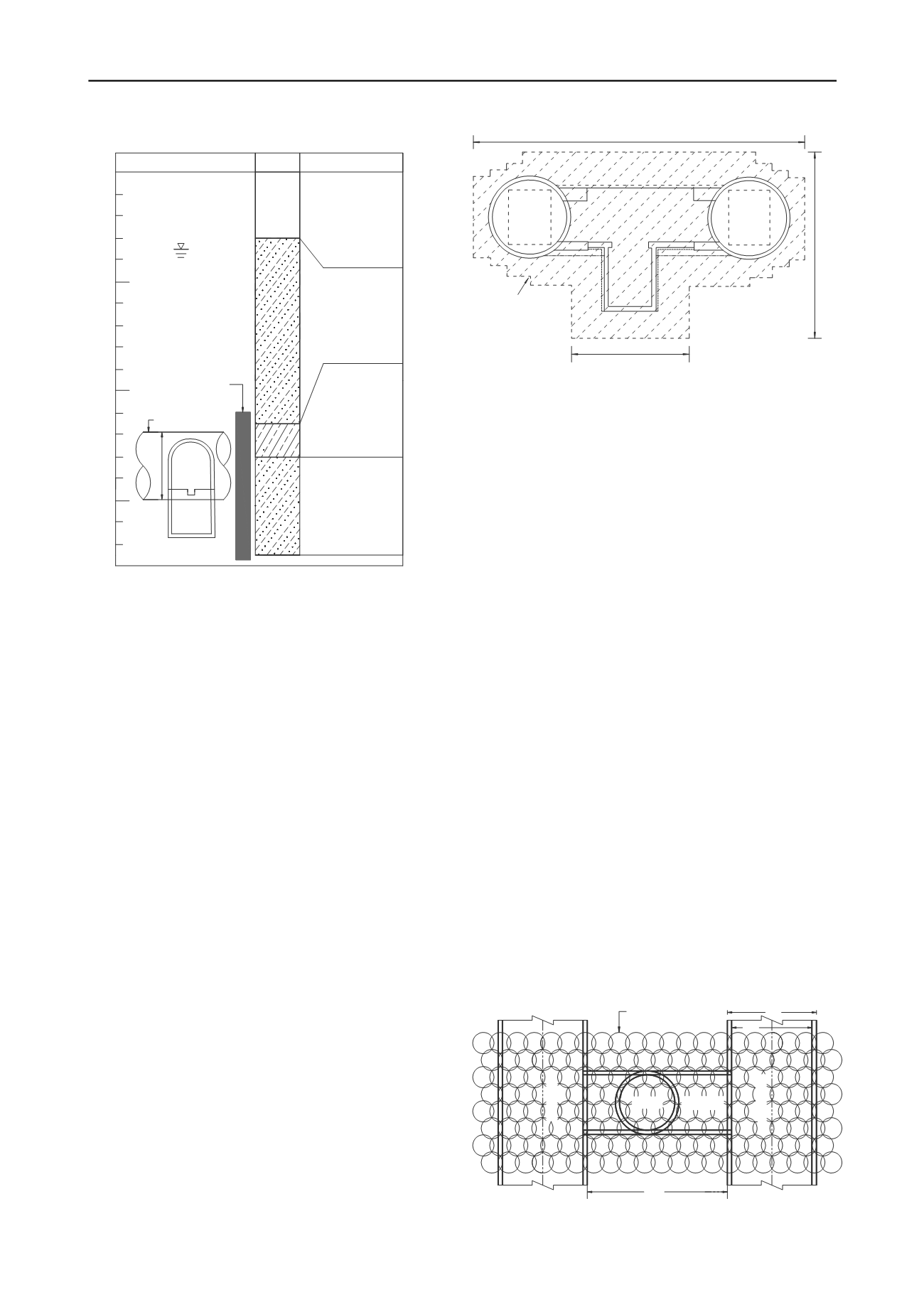

Depth (m)

Boring log

SB-16

Description

10

GWT

Surface fill (CL)

N = 3-7

w = 17.9%

w

L

= 21

w

P

= 8

Sublayer V

Silty sand (SM)

N = 14-22

w = 20.2-27.3%

Sublayer IV

Silty clay (CL)

N = 14-22

w = 23.3-33.1%

w

L

= 22-46

w

P

= 2-20

Sublayer III

Silty sand (SM)

N = 16-23

w = 16.9-23.8%

6m

26m

35m

SF

23m

20

30

Jet

grouting

zone

sump

Drainage

Cross

passage

6.1m

Shield Tunnel

13.5 m

23.5 m

8.2 m

Down-Track

tunnel

Up-Track

tunnel

Cross passage

Drainage

sump

JSG soil

improvement

Down-Track

Tunnel

Up-Track

Tunnel

Cross

passage

JSG

= 1.4 m

Drainage

sump

5.6 m

6.1 m

9.4 m

Figure 2. Geological profile for excavation of cross passage and

drainage sump. (after Continental Engineering Corp., 2003)

1992), Figure 2 shows the geological profile adjacent to the

cross passage. In the figure, the groundwater table was at about

7 m below ground level.

Figure 2 shows the cross passage was constructed at the depth

of 24.7 to 29.3 m. Plus the 4.4 m-deep drainage sump, the

excavation was extended to the depth of 33.7 m. Soils excavated

for the cross passage included silty clay (classified as CL) and

silty sand (classified as SM). Engineering properties of these

soil deposits, such as the natural water content w, standard

penetration test blow count N, liquid limit w

L

and plastic limit

w

P

were indicated in Figure 2.

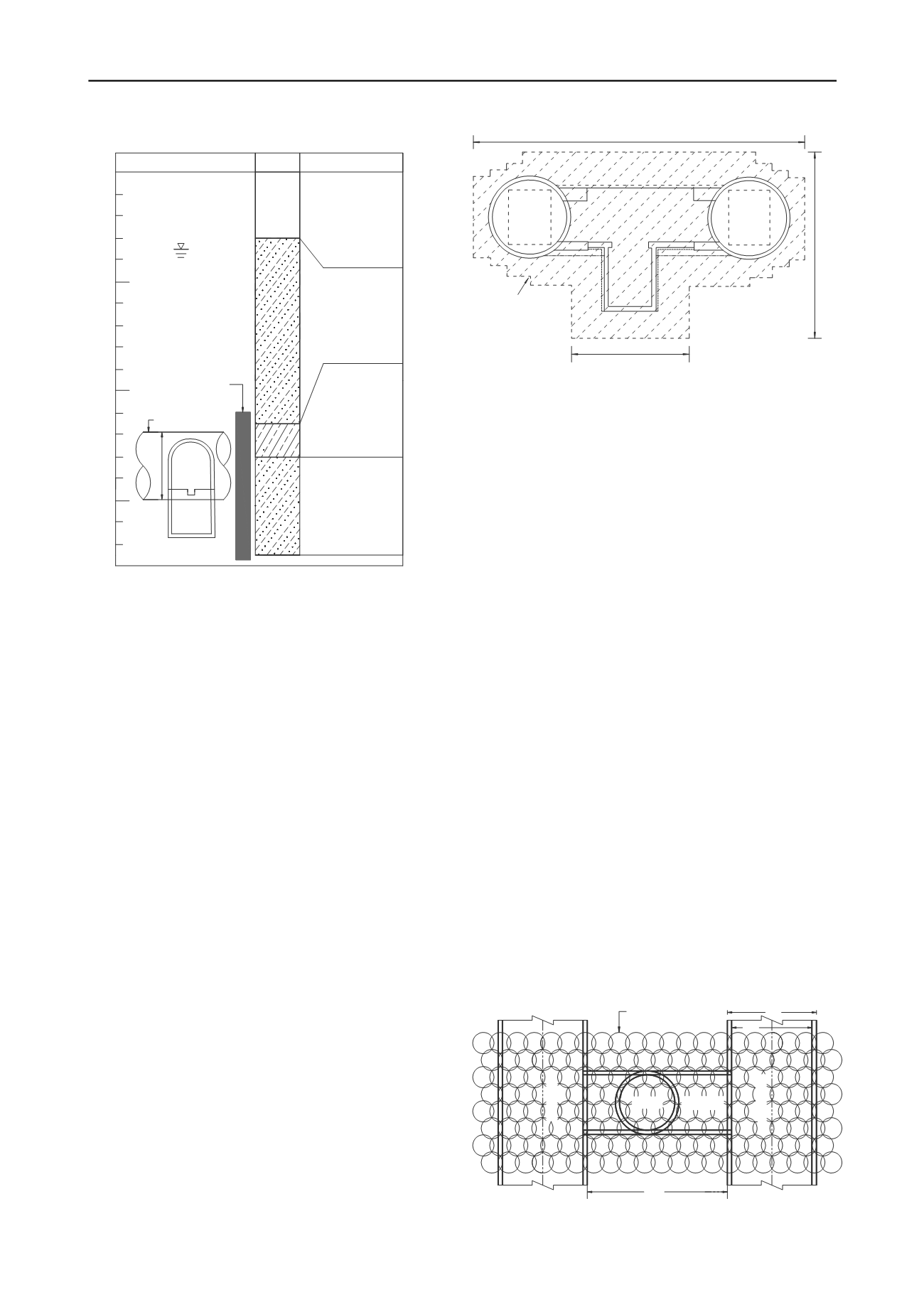

JSG (Jumbo Special Grout) operation was completed before

the shield machine arrived. Based on the size of the cross

passage and the recommendations of the Jet Grout Technical

Information (JJGA 1990), the grouting zone was 13.5 m-high,

and 8.2 to 23.5 m-wide as illustrated in Figure 3. Figure 4

shows a total of 168 1.4 m-diameter JSG piles were fabricated.

2.2

JSG operation and quality control

The technique of JSG utilizes high-pressure water-cement jet

streams (sheathed with air pressure) to cut, replace and mix with

native soils. For every 1 m

3

of jet grout, 600 kg of type I

Portland cement was mixed with 0.81 m

3

of water. The jetting

pressure was controlled at 19.6 MPa (200 kgf/cm

2

), and the rate

of flow was 0.06 m

3

/min. The air pressure used was 0.6 to 0.7

MPa (6 to 7 kgf/cm

2

). The grouting rod was controlled to rotate

at 6 to 7 r.p.m., and to uplift at the speed of 2.0 m/hr.

After ground improvement, soilcrete cores were drilled and

field permeability tests were carried out. The minimum core

recovery of 80% and the maximum coefficient of permeability

of 1 x 10

-7

m/s were required for the improved body. 28 days

after grouting, the design specification requires the uniaxial

compressive strength of sample obtained from sandy and clayey

layer should reach at least 2.94 MPa (30 kgf/cm

2

) and 0.98 MPa

(10 kgf/cm

2

), respectively. For more information regarding the

JSG application for the construction of Taipei MRT, the reader

is referred to Fang and Chung (1997), Fang and Yu (1998), and

Figure 3. Section of JSG ground improvement for cross passage.

Fang et al. (1993, 1994a, 1994b).

3 CONSTRUCTION OF CROSS PASSAGE

3.1

Preparation

Due to the pushing, cutting and disturbing of the cutter disc of

the EPB shield tunneling machine, cracks and discontinuities in

the improved ground might be induced. As a result, the

water-leak test on the jet-grouted body became necessary.

Figure 5 shows holes were drilled from the tunnel to the

soilcrete to investigate the quality of ground modification. The

holes should not penetrate the improved ground as to create new

intruding paths for groundwater. When a significant amount of

water-leak was measured in the tunnel (see Figure 6), additional

chemical grouting was conducted as indicated in Figure 7. Low

pressure grout with a mixture of water-glass and SL reaction

agent was injected to the improved ground to seal all water

paths around the cross passage.

To repress the inflow of groundwater at the face of

excavation, and to increase the safety of construction, the

compressed-air method was employed. The air-lock used is

shown in Figure 8. For most of the working days, the air

pressure was kept at 60 to 80 kPa, and the maximum air

pressure used was about 180 kPa.

For the mining of the cross passage, circular holes were cut

on the steel segments of the main MRT tunnels. The load

release on the opening would cause a redistribution of pressure

on the tunnel lining, and a possible stress concentration on

adjacent lining segments. For this reason, Figure 9 shows the

contractor fabricated octagonal steel reinforcements on both

sides of the opening in the tunnel for protection.

3.2

Excavation

The excavation of cross passage was conducted manually. The

digging was divided into four parts: (1) top heading (the upper

part); (2) bench (the middle part); (3) invert (the lower part);

Figure 4. Plan of JSG ground improvement for cross passage.