1732

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

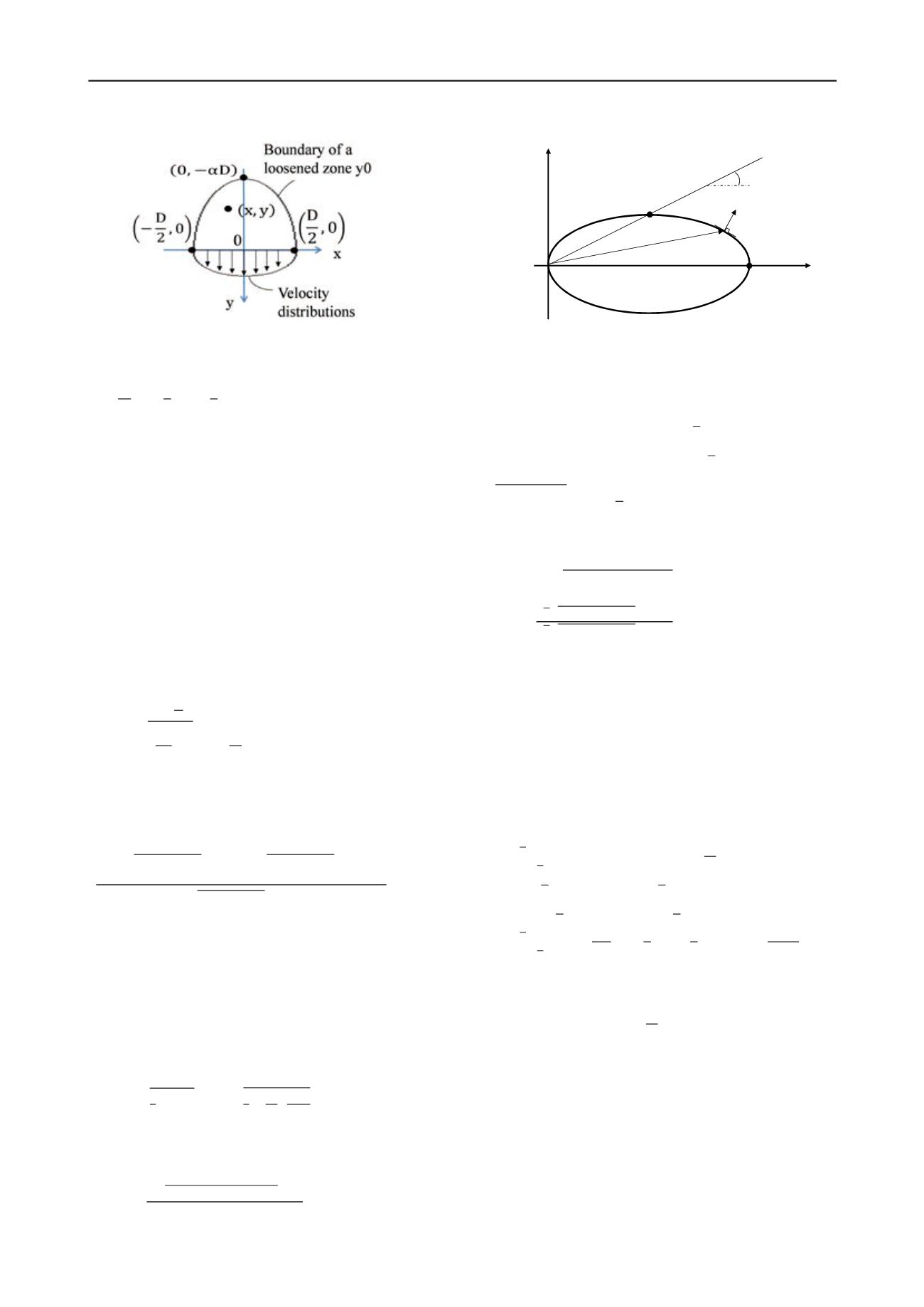

0,

βy

,

0,

(1)

A parameter

α

stands for a size of a loosened zone with respect

to the width D. Another parameter

β

is a magnitude of a

velocity which can be negligible due to the first order of

homogenuity in upper bound calculations.

2.2 Calculation of dissipation rate

Internal dissipation rate per unit volume can be expressed as in

Eq. (2) in terms of mean effective stress

p’

and deviatoric stress

q

.

w

σ

∙ ε

p′ ∙ ε

q ∙ ε

(2)

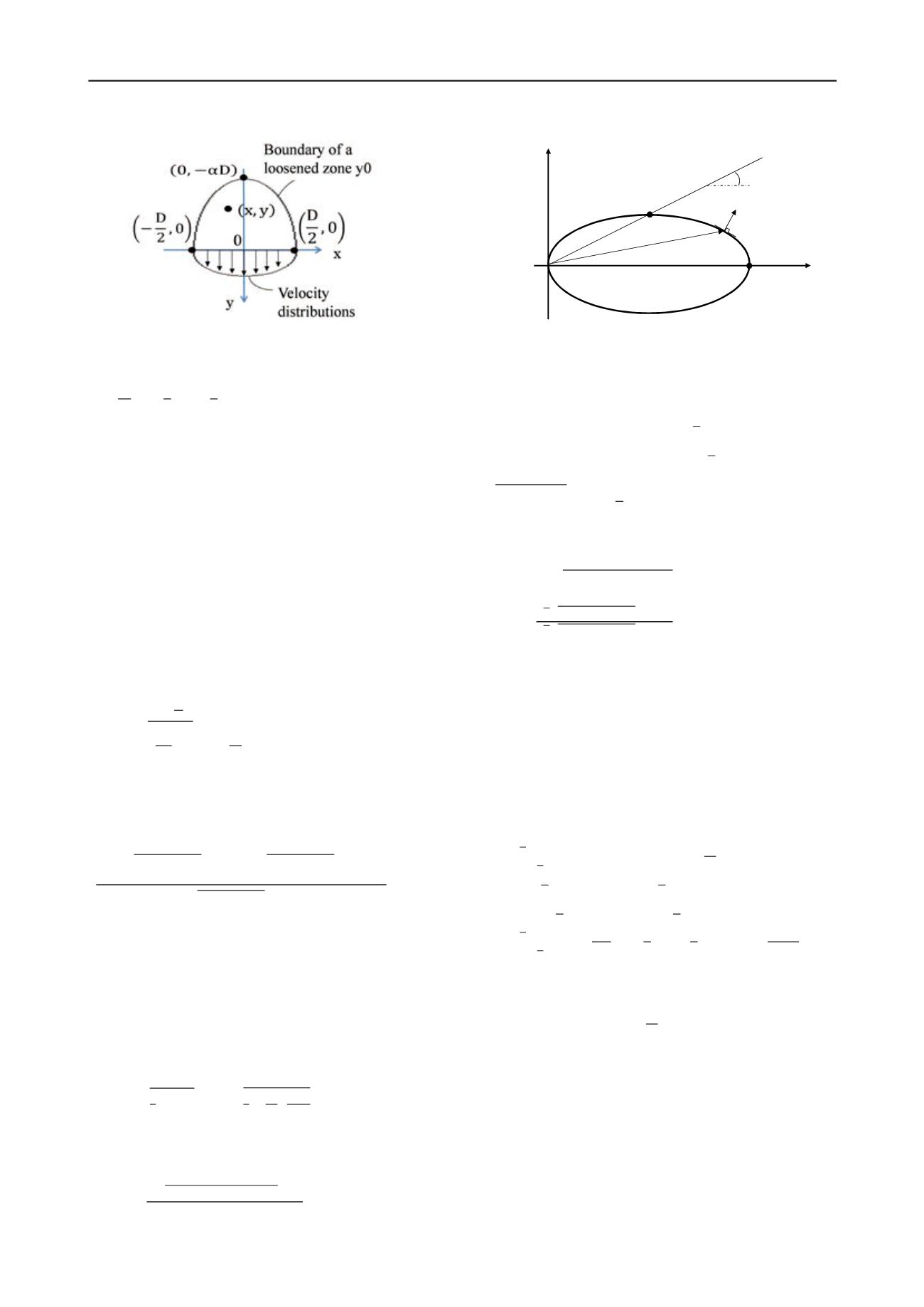

For a case of modified Cam-clay model (Figure 3), internal

dissipation rate should be derived from its yielding function (Eq.

3) and associated flow rule (Eq. 4) :

f p

∙

p

=0

(3)

ε

λ ∙

ε

λ ∙

(4)

Concrete form of internal dissipation rate for modified Cam-

clay soil is as follows,

w

ε

ε

ε

ε

ε

ε

ε

p

(5)

where

p

and

M

stand for a maximum consolidation stress and a

gradient of a critical state line which is can be uniquely

determined by tri-axial compression tests.

Volumetric plastic strain rates

ε

and deviatoric plastic

strain rates

ε

for assumed failure modes are as follows,

ε

ε

ε

ε

β

(6)

ε

e

e

β

∙

(7)

By substituting Eqs. (6) and (7) into Eq. (5), internal dissipation

rate per unit volume is shown as

w

∙ p

(8)

Total internal dissipation rate is then calculated by integrating

Eq. (8) over a volume,

W

w

x ∙ dv 1 ∙ w

dx dy

p

βD

55296α

M

18432

√34

9192

4

9

(9a)

Where

A

and

k

are as follows,

A 48

4

9 2304

96

216

(9b)

k log

√

√

(9c)

In this formulation, a closed-form solution of

W

can be

obtained.

2.3 Calculation of external plastic work rate

External plastic work rate consists of two terms;

W

done by

self-weight of a soil in a loosened zone and

W

due to

uniform upward pressure q.

W

γ u

dv

γ ∙ βy y

dv

=

γ ∙ βy y

dy dx

γα

βD

(10)

W

q ∙ u

dx

=

q ∙ βy

dx

=

q ∙

x

x

dx

(11)

External plastic work rate

W

is then calculated as follows,

W

W

W

αβD

4γ αD 10q

(12)

2.4 Evaluation of uniform pressure q to stabilize a trap

door

According to the upper bound theorem, a following inequality

holds if a structure is stable for the assumed failure mechanism:

W

W

(13)

Therefore, by equilibrating internal dissipation rate and external

plastic work rate in eq. (13) and arranging them with respect to

a uniform upward pressure q, a following equation can be

derived,

Figure 2. Assumed failure mode and velocity distributions

Figure 3. Modified Cam-clay model and associated flow rule

0

M

(p

y

’,0)

q, ε

d p

ε

ij p

ε

v p

,

ε

d p

σ

ij

p′, ε

v p