1658

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Table 1. Measured maximum accelerations of the shake table and the

ackfill (the values are in g)

b

Shake

table Box Layer 1

(bottom)

Layer

2

Layer

3

Layer

4

Layer 5

(top)

1.89

1.56

1.75

1.87

1.77

2.16

2.25

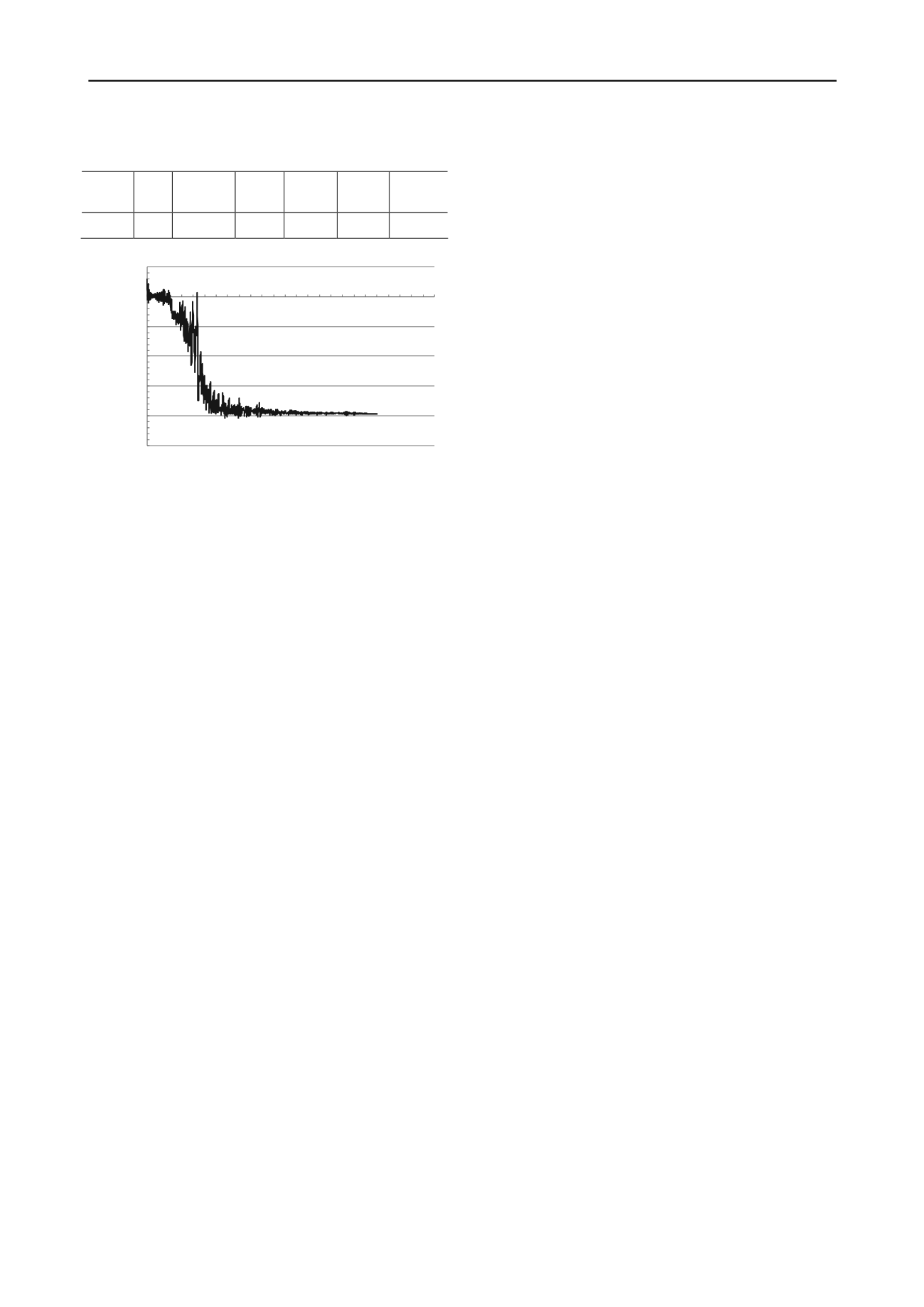

Figure 7 Seismic vertical settlements of MSE wall (measured at the top

of the backfill)

Figure 7 shows the seismic vertical settlements measured by

the LVDT transducers at the top of the wall. Two LVDT

transducers were positioned at the top and they recorded

similar settlements. Therefore, only the readings from one

LVDT were shown in the figure. In the first 10 to 15 seconds, a

maximum vertical settlement of approximately 2 cm was

recorded. After that, the settlement remained at approximately

2 cm. This initial settlement could be due to the lack of

complete compaction of the TDA. Due to calibration errors, the

vertical stresses that were recorded by the dynamic soil

pressure cells in the backfill were considered incorrect and

were not presented in this paper.

4 CONCLUSIONS AND LIMITATIONS OF THIS

RESEARCH

This paper presents a preliminary experimental research on the

seismic responses of a reduced-scale geogrid-reinforced

retaining wall with TDA backfill under the simulated Loma

Prieta earthquake excitations. The research used a shake table

to produce the scaled earthquake motions. Overall the wall with

TDA backfill performed well with no apparent damage. The

maximum horizontal deflection of the wall face occurred at the

top of the wall and was 7 cm, or 4.7% of the wall height. Due

to the difficulty in achieving higher density, the TDA had a

small settlement (approximately 2 cm) in the first 10-15

seconds, or 1.3% of the wall height.

This experimental study has several limitations. (1) The

geogrid’s tensile strength was not scaled, this could result in an

over-reinforced wall. (2) The reinforcement was based on static

design. Seismic design using the methodologies presented by

Helwany et al. (2012) and by National Concrete Masonry

Association (NCMA 2010) may change the internal

configuration of the MSE wall and consequently the seismic

behavior. (3) The scaling law used in the model test should be

improved to consider the scaling of the TDA-geogrid

composite material properties. (4) External (global) stability,

such as deep-seated rotational failure that can be caused by

earthquakes, cannot be simulated in this test due to the shallow

soil depth. Because of these limitations, extrapolation of the

model results to the field is premature at this stage. This

research work is continued to address the limitations in (1), (2),

and (3). Furthermore, numerical model using Plaxis is being

developed to simulate the laboratory conditions (including the

boundary conditions, material properties, and seismic

excitations). Using the same conditions, the numerical model

can be calibrated using the model test results; then the

numerical model can be used to predict the seismic

performance of this type of retaining walls in the field.

5 ACKNOWLEDGEMENTS

This project is funded by the California Department of

Transportation, USA (agreement number: 65A0449). Steve

Scherer in the Department of Civil and Geomatics Engineering

at CSU Fresno helped the experimental setup. Mr. Cameron

Wright of West Coast Rubber Recycling (Hollister, CA)

provided the TDA; Mr. Willie Liew of Tensar International

provided the geogrid. We appreciate these supports.

-2.5

-2

-1.5

-1

-0.5

0

0.5

0

10

20

30

40

5

Vertical Displacement (cm)

Time (sec)

0

6 REFERENCES

Bosscher, P. J., Edil, T. B., and Eldin, N. N. 1992. Construction and

performance of a shredded waste tire test embankment.

Transportation Research Record

.

1345

, Transportation Research

Board, Washington, D.C., 44–52.

Federal Highway Administration, U.S. Department of Transportation.

1997. User Guidelines for Waste and Byproduct Materials in

Pavement Construction. Publication Number: FHWA-RD-97-148.

Federal Highway Administration, U.S. Department of Transportation

2008. Geosynthetic Design and Construction Guidelines

Reference Manual. Publication No. FHWA-NHI-07-092, by Holtz,

R.D., Christopher, B.R., and Berg, R.R. National Highway

Institute. Washington, DC. August 2008.

Gazetas, G. 1991 Formulas and charts for impedances of surface and

embedded foundation.

ASCE Journal of Geotechnical Engineering

,

117(9), 1363-1381.

Hazarika, H., Kohama, E., and Sugano, T. 2008. Underwater Shake

Table Tests on Waterfront Structures Protected with Tire Chips

Cushion. ASCE

J. of Geotech. and Geoenviron. Engrg

, 134(12),

1706-1719.

Helwany, S., Wu, J.T.H., and Meinholz, P. (2012). Seismic Design of

Geosynthetic-Reinforced Soil Bridge Abutments with Modular

Block Facing. Final Report for NCHRP Project 12-59 (01).

American Association of State Highway and Transportation

Officials (AASHTO), Washington, D.C.

Humphrey, D. N. 1998. Highway applications of tire shreds.

New

England Transportation Consortium Rep.

, September.

Humphrey, D. N., and Manion, W. P. 1992. Properties of tire chips for

lightweight fill.

Proc. Conj. on Grouting, Soil Improvement, and

Geosynthetics,

2 ASCE, New York, 1344-1355.

Koerner, R.M. 2005.

Designing with Geosynthetics

. fifth Edition.

Pearson Prentice Hall. Upper Saddle River, NJ.

Moncarz, P., and Krawinkler, H. 1981. Theory and application of

experimental model analysis in earthquake engineering. The John

A. Blume Earthquake Engineering Center, Stanford University. A

report on a research project sponsored by the National Science

Foundation, Grants ENV75-20036 and ENV77-14444, June 1981.

National Concrete Masonry Association (NCMA) (2010). Seismic

Design Of Segmental Retaining Walls, TEK 19-5A. National

Concrete Masonry Association, Herndon, Virginia.

Strenk, P.M., Wartman, J., Grubb, D.G., Humphrey, D.N., Natale M.F.

2007. Variability and scale-dependency of tire-derived aggregate.

ASCE J. Materials in Civil Engineering

, 19(3), 233-241.

Tandon, V., Velazco, D.A., Nazarian, S., and Picornell M. 2007.

Performance monitoring of embankments containing tire chips:

case study.

ASCE J. of Performance of Constructed Facilities

,

21(3), 207-214.

Tsang, H. H. 2008. Seismic isolation by rubber-soil-mixtures for

developing countries.

Earthquake Engineering and Structural

Dynamics

, 37, 283-303.

Tweedie, J.J., Humphrey, D.N., Sandford, T.C. 1998. Tire shreds as

lightweight retaining wall backfill: active conditions.

ASCE J.

Geotech. and Geoenvir. Eng

., 124(11), 1061-1070.