1656

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

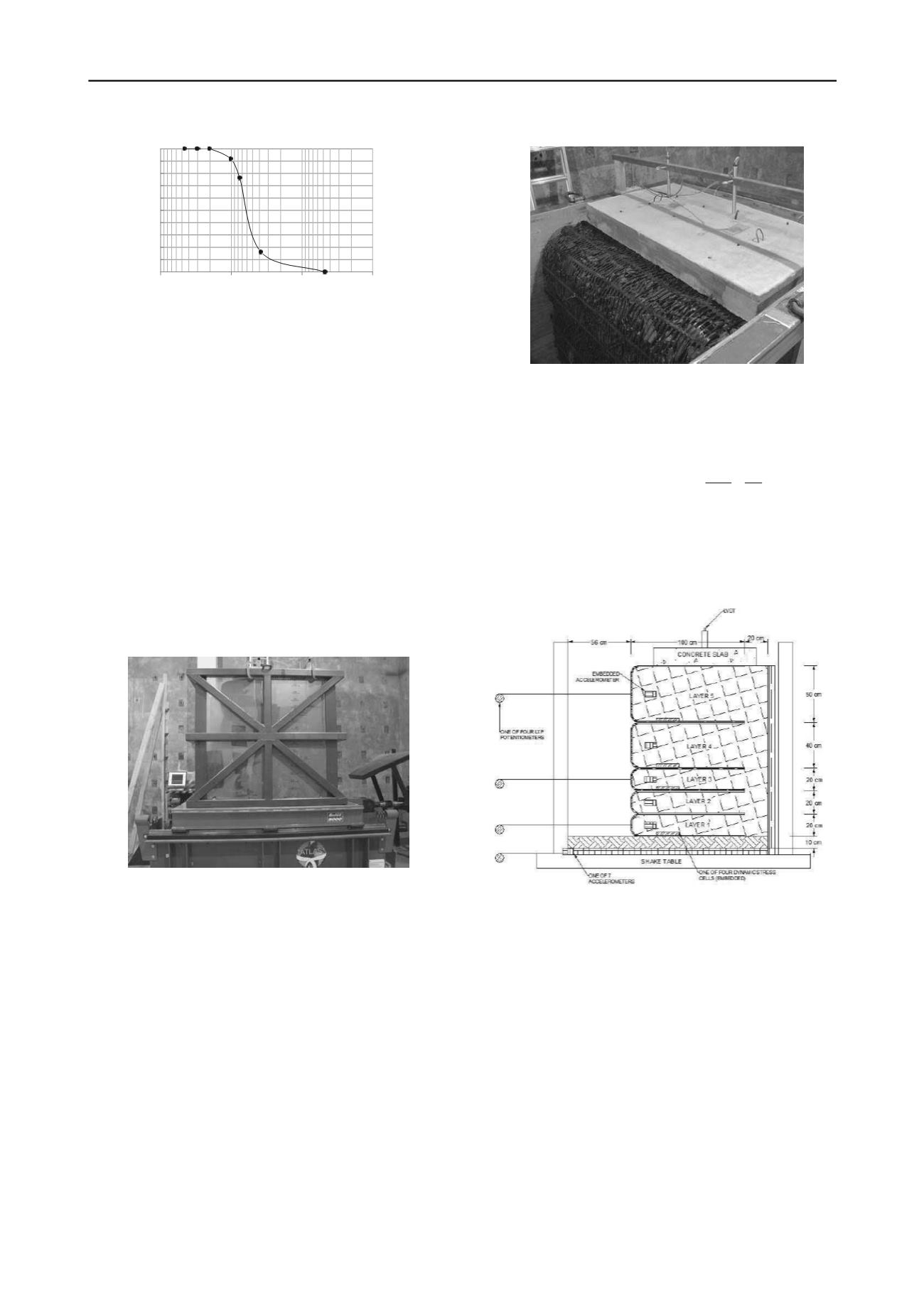

0

10

20

30

40

50

60

70

80

90

100

0.1

1

10

100

Percent Finer by Mass (%)

Aggregate Size (cm)

Figure 1. Size distribution of the TDA

Young’s modulus of the TDA was also obtained using a

large-scale compression test. The dimensions of the TDA

sample in the compression test was 112 cm long, 71 cm wide,

and 50 cm tall and was confined in a wooden box. The stress-

strain relationship, which was not included in this paper due to

page limit, showed an apparent upswing trend as the

compressive deformation continued. Within 10% strain, the

curve appeared to be a linear line, and the Young’s modulus of

the TDA is approximately 400 kN/m

2

. The bulk density of the

TDA in the backfill was 721 kg/m

3

, which is at the lower end

of the density range that is used in the engineering practice.

Higher density was not able to be reach due to the compaction

capability in the lab. In order to obtain the shear resistance of

the TDA, large scale shear testing was conducted. The shear

resistance of the TDA was found to be approximately

c

= 0,

=

30

.

2.2 Experimental Setup

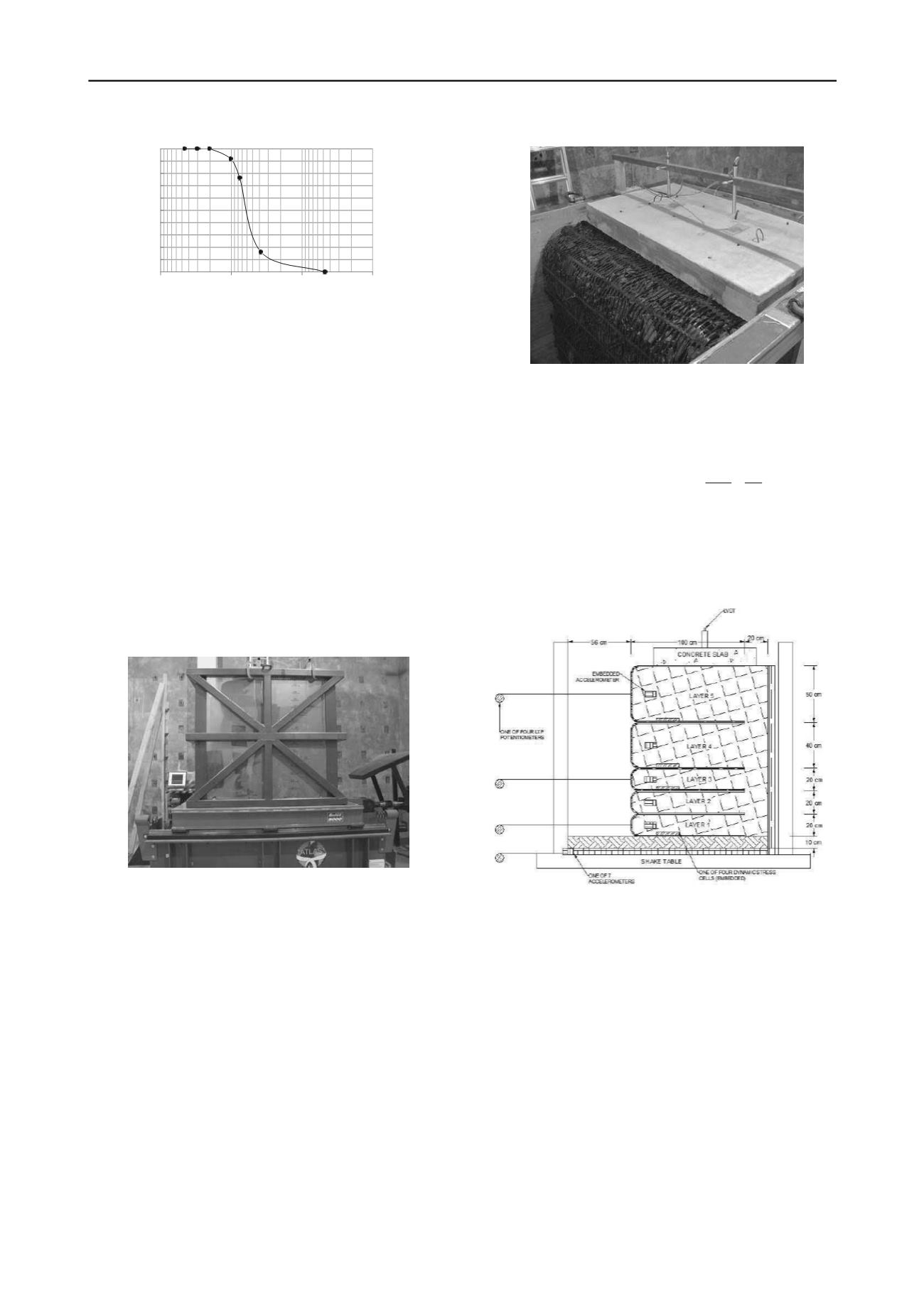

Figure 2. Shake table

A section of reduced-scale MSE wall was built in a 1.5 m

1.87 m

1.8 m rigid steel box that was anchored on a 2.4 m

2.1 m one-dimensional shake table. The load capacity of the

shake table is 177.9 kN, the actuator provides 245 kN of

hydraulic driving force, and the maximum travel distance of the

table is

12.7 cm. The shake table is capable of replicating

recorded historical earthquake motions that are within the

table’s allowable displacement range. Figure 2 is a photo of the

shake table and the box with a retaining wall built inside.

Figure 3 shows the completed model MSE wall with TDA

backfill.

The model MSE wall’s configuration is shown in Figure 4.

The wall was 1.5 m high, 1.2 m deep, and 1.5 m long. Five

wrap-around layers of reinforced TDA were used. Uniaxial

geogrid was used for both reinforcement and containment of

the TDA. The spacing and length of each reinforcement layer

were determined according to the “Geosynthetic Design &

Construction Guidelines Reference Manual” (FHWA 2008)

and “Designing with Geosynthetics” (Koerner 2005).

Figure 3. Constructed model MSE wall

The design parameters for the geogrid reinforcement are

listed as follows:

Ultimate tensile strength:

T

ult

= 54 kN/m

Total reduction factors:

RF

= 3.6

Allowable tensile strength:

T

all

T

ult

RF

54

3.6

15 kN/m

Factor of safety for pullout failure: FS = 1.5

Height of wall (prototype):

H

= 4.5 m

External friction angle (

) between geogrid and TDA:

assume

=

TDA

= 30

Adhesion between geogrid and TDA:

c

a

= 0.

Figure 4. Configuration and instrumentation of MSE wall

Beneath the first layer of the TDA, a 10 cm sand layer was

compacted to simulate the friction of the base soil. It is noted

that in each of the wrap-around layer, the top geogrid sheet is

only half of the length of the bottom geogrid sheet for that

layer, since the top wrap-around sheet was not intended to

serve as a reinforcement layer. The TDA were compacted using

a 15 kg hand hammer with a long handle and 30 cm

30 cm

steel base to reach the target density of 721 kg/m

3

. A concrete

slab was placed at the top of the wall and anchored to the top

layer with ten steel rebar, so that the slab did not move freely

during the shaking. The concrete slab simulated a surcharge of

3.4 kN/m

2

. Transparent Plaxiglas sheets were used at the

interface between the TDA wall and the sides of the box to

minimize the friction between the TDA and the boundaries.

Figure 4 also depicts the instrumentations used in the model

test. Three linear potentiometers were used to measure the

horizontal deflections of the wall face at the bottom, middle,

and top layers. The potentiometers were fixed to an inertial

frame outside of the shake table, and an inelastic wire