1664

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2

used for the low ground pressure tests and T-Rex was used for

higher ground pressure tests.

The mobile shakers were first used to apply a static vertical

load increment on the foundation. The foundation settlement

during static load application was measured from spanning

beams. The vertical load was varied, allowing for an in situ

assessment of the effect of vertical stress in the MSW. The

sequence of applied vertical loads is shown in Fig. 3. At each

vertical load increment, small-strain crosshole and downhole

seismic testing was performed. Then, a 30-50 Hz sinusoidal

horizontal load at increasing load amplitudes was applied by the

mobile shakers and the ground motion was captured by the

geophones embedded in the waste. Upon completion of testing,

the waste was excavated and in situ unit weight tests were

performed as described in Zekkos et al. (2006).

3 DATA INTERPRETATION

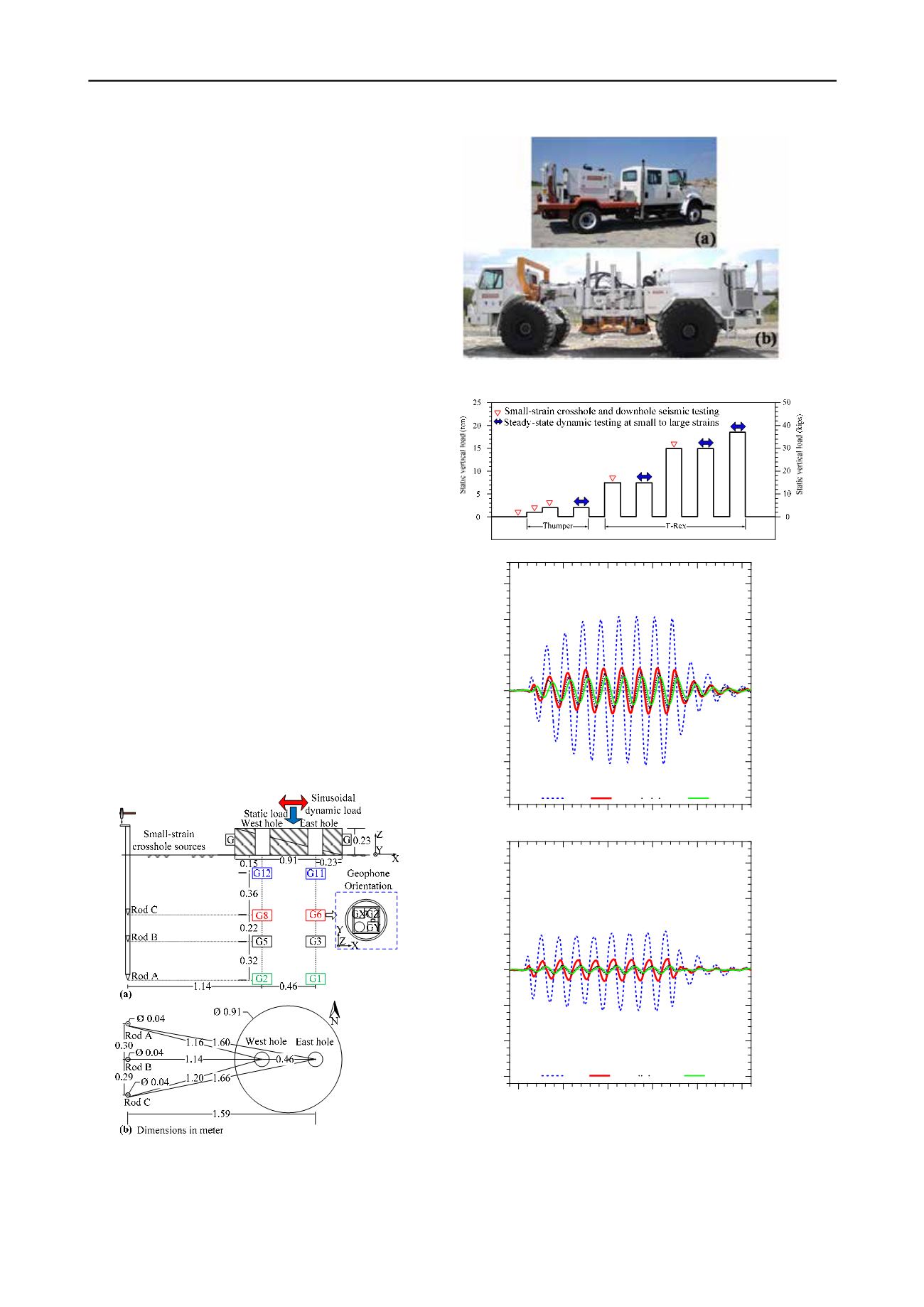

The waves generated during cyclic loading by the mobile

shakers propagated downwards and were sensed by three-

component geophones in each vertical array. Examples of

dynamic loading time histories in the horizontal and vertical

directions of shaking are shown in Figs. 4a and 4b, repectively.

Shear wave velocity was calculated using the travel time of the

waves that propagate from the shallower to the deeper sensors.

The equivalent shear modulus was calculated using the in-situ

measured MSW unit weight. To assess the shearing strain

amplitude, the three-component displacement time history was

calculated by integrating the recorded velocity time history. A

4-node element was used by selecting pairs of geophones at two

different depths (Chang 2002) and the shearing strain time

history was then calculated for the element, as shown in Fig. 5.

Use of a 2-node approach (one sensor at each depth) or ignoring

the vertical displacement component (shown in Fig. 4b) in

calculating the shearing strain was found to underestimate the

shearing strain.

At each vertical load increment, vertical and horizontal stress

distributions were calculated using Foster and Ahvlin (1954).

By varying the dynamic load from low to high amplitudes, the

shear modulus reduction was evaluated. The effect of confining

stress on the shear modulus reduction was evaluated by varying

the vertical load increment. Different pairs of geophones were

selected to define a 4-node element, as shown in Fig. 6, to allow

an in-situ assessment of MSW variability.

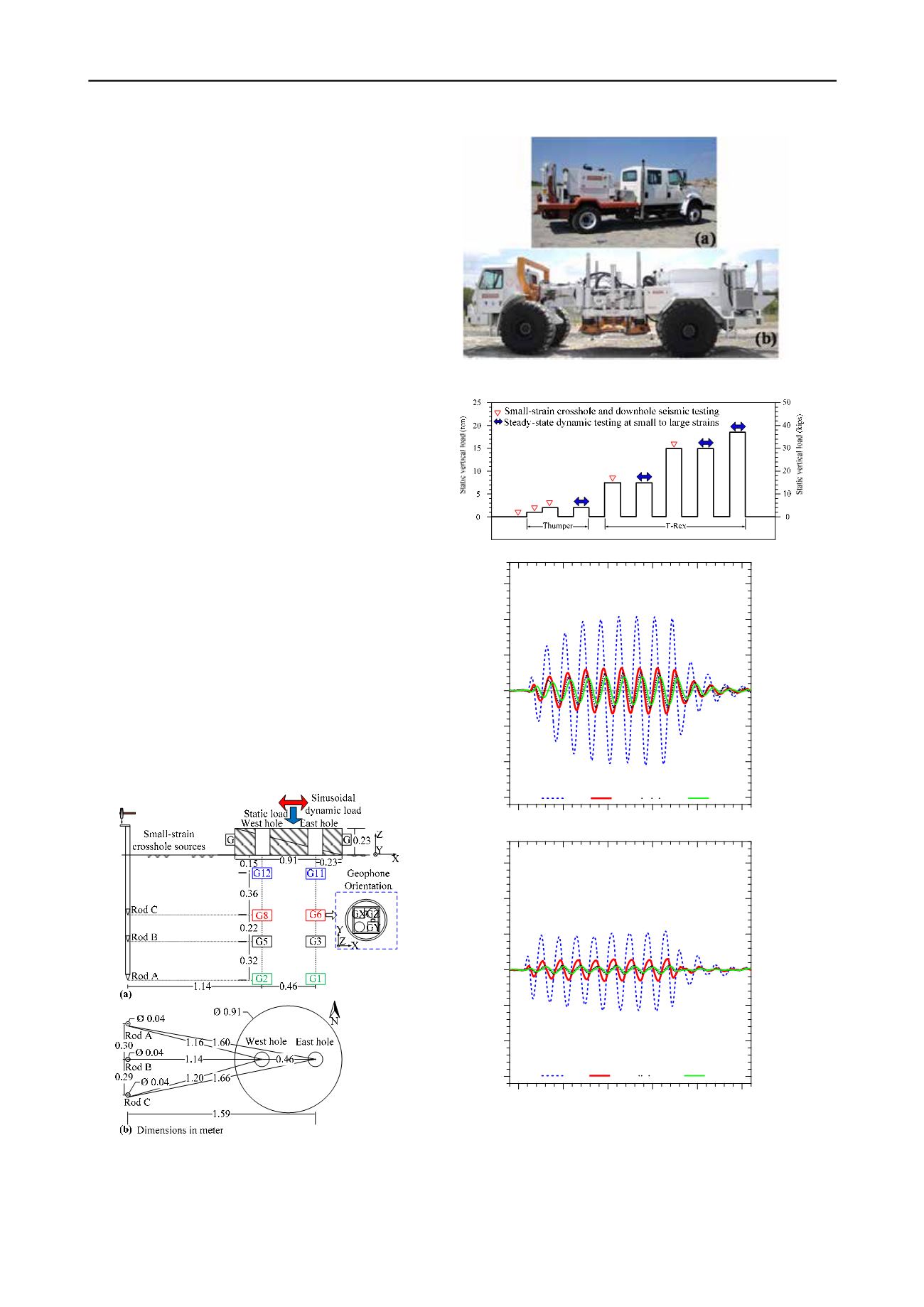

Figure 1: Schematic of the testing setup at location #1: (a) cross-section;

(b) plan view.

Figure 2: Photographs of large mobile shakers used to apply static and

dynamic loads to the MSW: (a) Thumper and (b) T-Rex.

Figure 3. Sequence of static loading and dynamic testing at location #1

Figure 4. Time-history records from the four geophones (G2, G5, G8,

G12) in one vertical array: (a) X axis (horizontal shaking direction) and

(b) Z axis (vertical shaking direction).

0.15

0.10

0.05

0.00

-0.05

-0.10

-0.15

Output Amplitude (volt)

250

200

150

100

50

0

Time (msec)

(a)

Shaker: Thumper

Vertical static load ~ 2 tons

Hor. dynamic load ~ 0.25 ton; Exc. Freq: 50 Hz (8 cycles)

G12X

G8X

G5X

G2X

0.15

0.10

0.05

0.00

-0.05

-0.10

-0.15

Output Amplitude (volt)

250

200

150

100

50

0

Time (msec)

(b)

Shaker: Thumper

Vertical static load ~ 2 tons

Hor. dynamic load ~ 0.25 ton; Exc. Freq: 50 Hz (8 cycles)

G12Z

G8Z

G5Z

G2Z